Aprašymas

About Screw Elements

Screw elements are key components in extruders, and their design and material selection have a direct impact on the performance and efficiency of the entire machine. When evaluating the quality and suitability of screw elements, wear and corrosion resistance are two crucial indicators.

Wear resistance determines the ability of screw elements to resist wear during long periods of operation, which affects their service life and maintenance frequency. Corrosion resistance is related to the stability of screw elements in different chemical environments, particularly when dealing with more corrosive materials. This performance of corrosion resistance is particularly critical.

Therefore, a high-quality screw element not only needs to have good mechanical properties but also should be excellent in terms of wear and corrosion resistance to ensure the efficient and stable operation of the extruder.

Processing Features and Advantages

All component materials used are sourced from leading domestic brands or professional material suppliers in Europe. Elemental and metallographic analysis and inspection are conducted to ensure foolproof raw materials. The internal splines of all components are checked with a spline plug gauge to guarantee interchangeability.

- Powder high-speed steel processed using the European HIP process and components treated in strict accordance with the heating treatment process offer wear resistance and corrosion resistance equivalent to foreign first-line brands.

- Our professional technical team provides timely and accurate sample surveying and mapping design, as well as technical services for component combination.

- We have detailed technical information and special tooling fixtures for both domestic and foreign first-line brand hosts, enabling us to quickly provide spare parts services.

- Common components are kept in ample stock, allowing for same-day shipping, while new products can be delivered within 45 days.

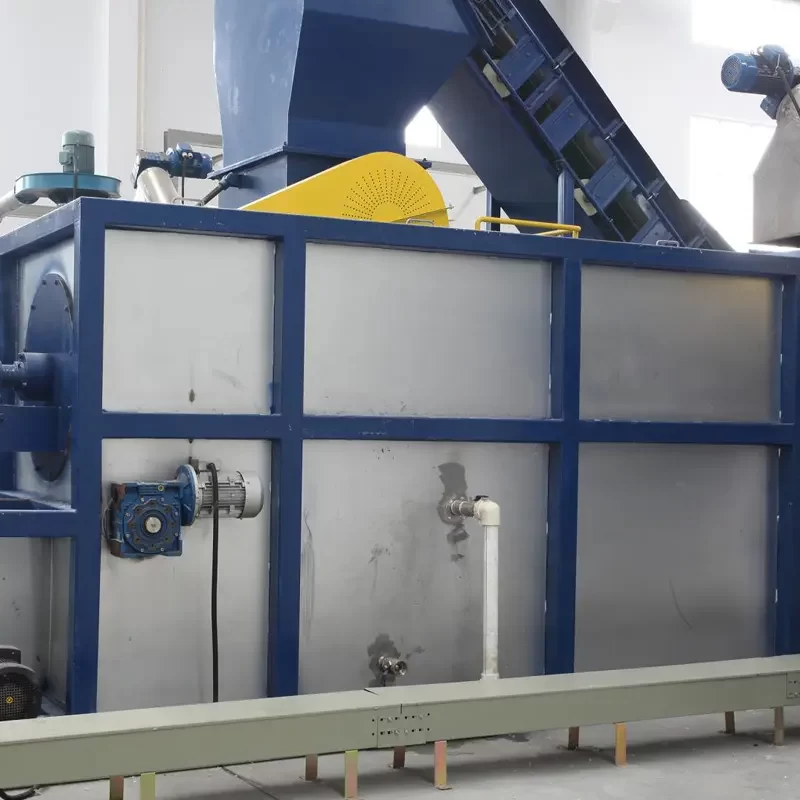

High-quality extruder screw elements for durable and reliable performance.

Pasiteiraukite dabar

Norėdami sužinoti naujausias kainas ir pristatymo laiką, atsiųskite mums žinutę naudodami žemiau esančią formą.

Rumtoo mašinos

Rumtoo mašinos Pasiteiraukite dabar

Pasiteiraukite dabar