Standard Plastic Granulator is a type of machinery designed specifically for crushing and processing plastic waste. It can quickly and effectively crush various types of plastic products, such as bottles, pipes, containers, and woven bags, into small particles, providing convenience for subsequent processing.

The working principle of the Plastic Crusher is to use a rotating cutter wheel to quickly cut and crush plastic waste into small pieces, which enter the sieve hole with the rotation of the cutter wheel and further crush into small particles. The crushed small particles can be directly used for plastic product manufacturing, or further processed and recycled.

Plastic Granulator is widely used in plastic recycling, waste disposal, and granulation. By using this equipment, waste pollution to the environment can be minimized, waste disposal costs can be reduced, and convenience is provided for plastic recycling. In addition, Plastic Crusher is easy to operate, safe, and reliable, and can be adjusted and optimized according to different material characteristics and processing requirements.

In summary, Plastic Granulator is an efficient, reliable, and environmentally friendly machinery that can be widely used for recycling and utilization of plastic waste, providing effective technical means for sustainable development.

Vigtigste tekniske parameter

[tabel-id=2 /]Our standard heavy-duty plastic granulator machines, sometimes called plastic crushers, are essential machines in theplastic recycling industry.

Arbejdsprincip

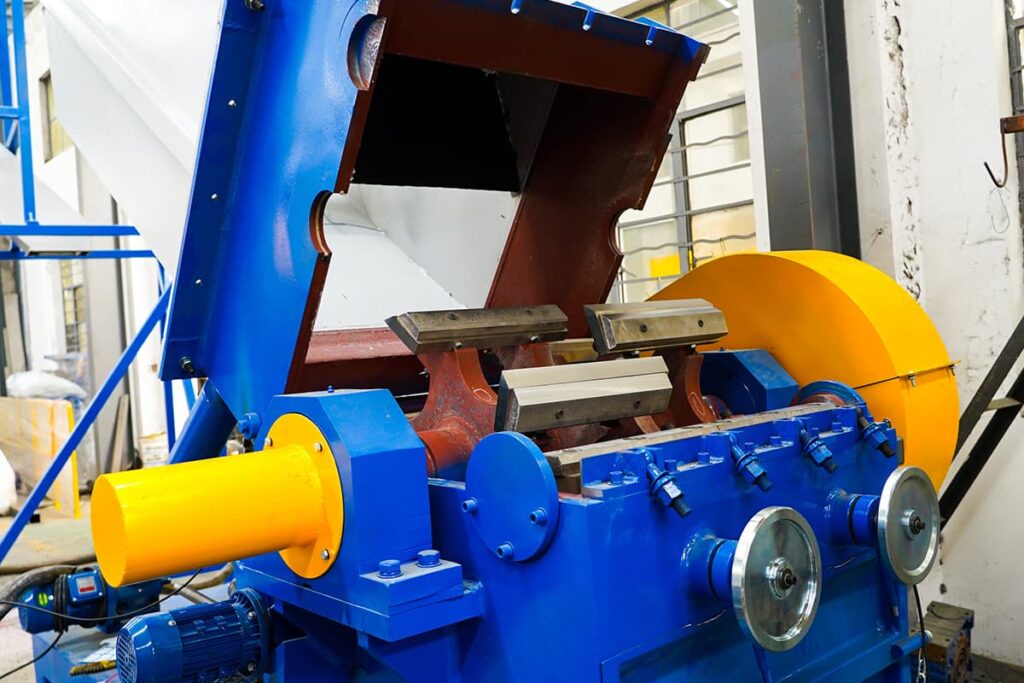

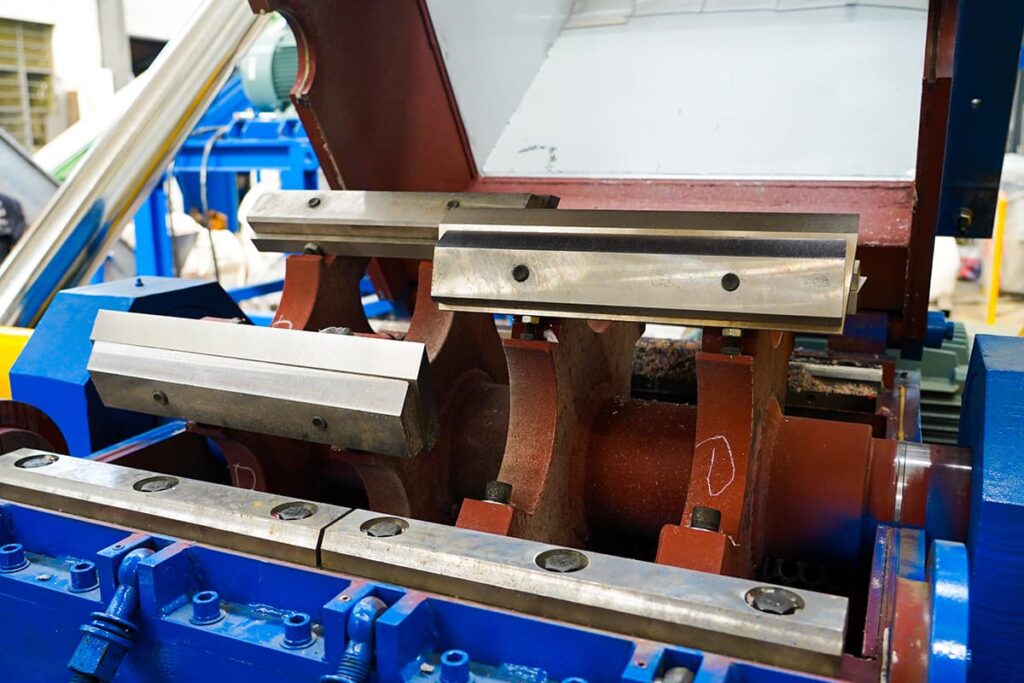

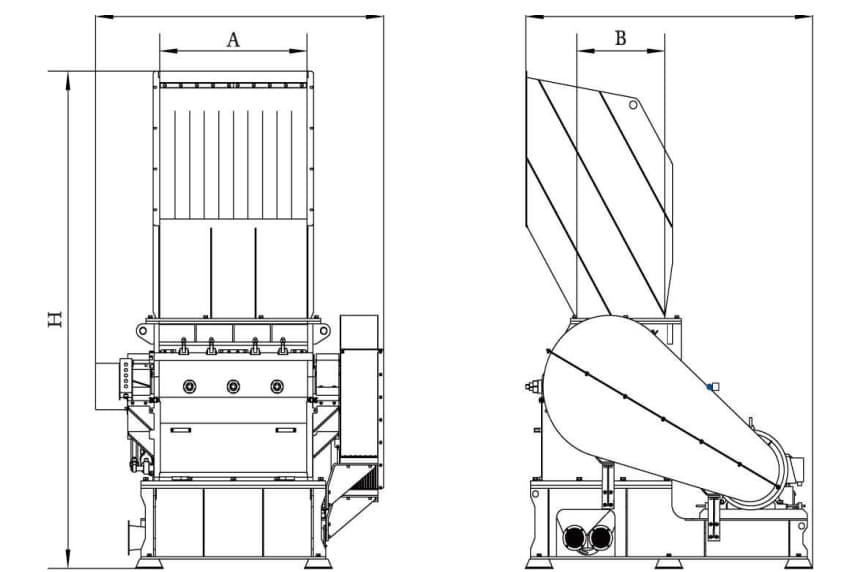

Our plastic granulator machine operates with an open rotor that is mounted with heavy-duty knives in either a double-scissor cut or v-shape array based on your needs. As the rotor spins at high speeds, its knives come into contact with stationary knives mounted within the cutting chamber. The material is continuously cut until it is small enough to pass through a screen filter. Our filter screens typically range from 10mm to 100mm, but can be customized according to your requirements. Our standard plastic granulator contains 12 rotor knives and 3 stationary knives. All knives use ultra-durable D2 (equivalent to SDK11) high-carbon, high-chromium steel, ensuring the longest usage times before requiring sharpening. The knives are easily adjustable with hydraulic-assisted access to the cutting chamber.

Features

- The blade adopts stepped distribution which can improve the cutting force and enhance working efficiency. Movable screen and dismounting convenience are easy for cleaning and changing. Sound insulation interlace is used in the feeding mouth to reduce the noise level and improve the working environment. A limited switch is installed in the feeding mouth to protect the operator’s safety.

- Main electrical components are trusted brands such as Siemens and Schneider.

- Hopper & cradle are hydraulically actuated for easy blade & screen replacement.

- Rotary and counter blades can be re-sharpened, greatly reducing operating cost.

Ansøgninger

This general purpose plastic granulator can be used for various applications of plastic recycling, including but not limited to grinding plastic bottles, films, and various small hard plastics.

Our plastic granulator is easy to operate, safe and reliable, and can be adjusted and optimized according to different material characteristics and processing requirements. In addition, using a plastic granulator can minimize environmental pollution, reduce waste disposal costs, and provide convenience for plastic recycling. It is an efficient, reliable, and environmentally friendly mechanical equipment, providing effective technical means for sustainable development.

Furthermore, for more convenience, we also provide wet plastic granulators, which have additional rubber seals and connected inlet hoses that allow continuous spraying of water during plastic cutting. This helps to clean plastic waste while keeping the blades cool during operation, thereby improving production efficiency and product quality.

Plastic Granulators VS Shredder Machines

Plastic granulators and shredder machines are both used in the recycling industry to process plastic waste, but they serve different purposes.

Plastic shredders are primarily used to reduce the size of bulky plastic products, such as large plastic containers, drums, and pipes, into smaller pieces that can be easily transported and processed. They use sharp blades to tear, shear, and slice the plastic waste into smaller pieces.

Plastic granulators, on the other hand, are used to process smaller plastic waste, such as plastic bottles, films, and small hard plastics, into small particles that can be directly used for plastic product manufacturing or further processed and recycled. They use rotating cutter wheels to cut and crush plastic waste into small pieces, which enter the sieve hole with the rotation of the cutter wheel and further crush into small particles.

Both plastic shredders and granulators can be adjusted and optimized according to different material characteristics and processing requirements. Choosing the right equipment depends on the type and size of plastic waste being processed, as well as the desired output size and quality.

Garanti

Alle genbrugsmaskiner leveres med 1 års begrænset garanti.

Spørg nu

For at få de seneste priser og leveringstider, send os en besked ved at bruge formularen nedenfor.

Gengivelse er ikke tilladt uden tilladelse.:Rumtoo Maskiner » Standard plastgranulator

Rumtoo Maskiner

Rumtoo Maskiner Spørg nu

Spørg nu