Kuvaus

This document outlines the key considerations and design elements for a Power Take-Off (PTO) frame used in a PVC/Nitrile glove production line.

1. Purpose:

The PTO frame serves as a mechanical interface between the main drive motor and various downstream equipment in the glove production line. It transmits power from the motor to components like:

-

Extruder: Melts and extrudes the PVC/Nitrile compound.

-

Forming Machine: Shapes the extruded material into glove molds.

-

Curing System: Vulcanizes the gloves.

-

Other Auxiliary Equipment: Such as beading machines, washing systems, and drying units.

2. Design Considerations:

-

Power Requirements:

-

Determine the torque and speed requirements of each downstream equipment.

-

Calculate the total power demand and select a motor with sufficient capacity.

-

Consider future expansion and potential increases in production volume.

-

-

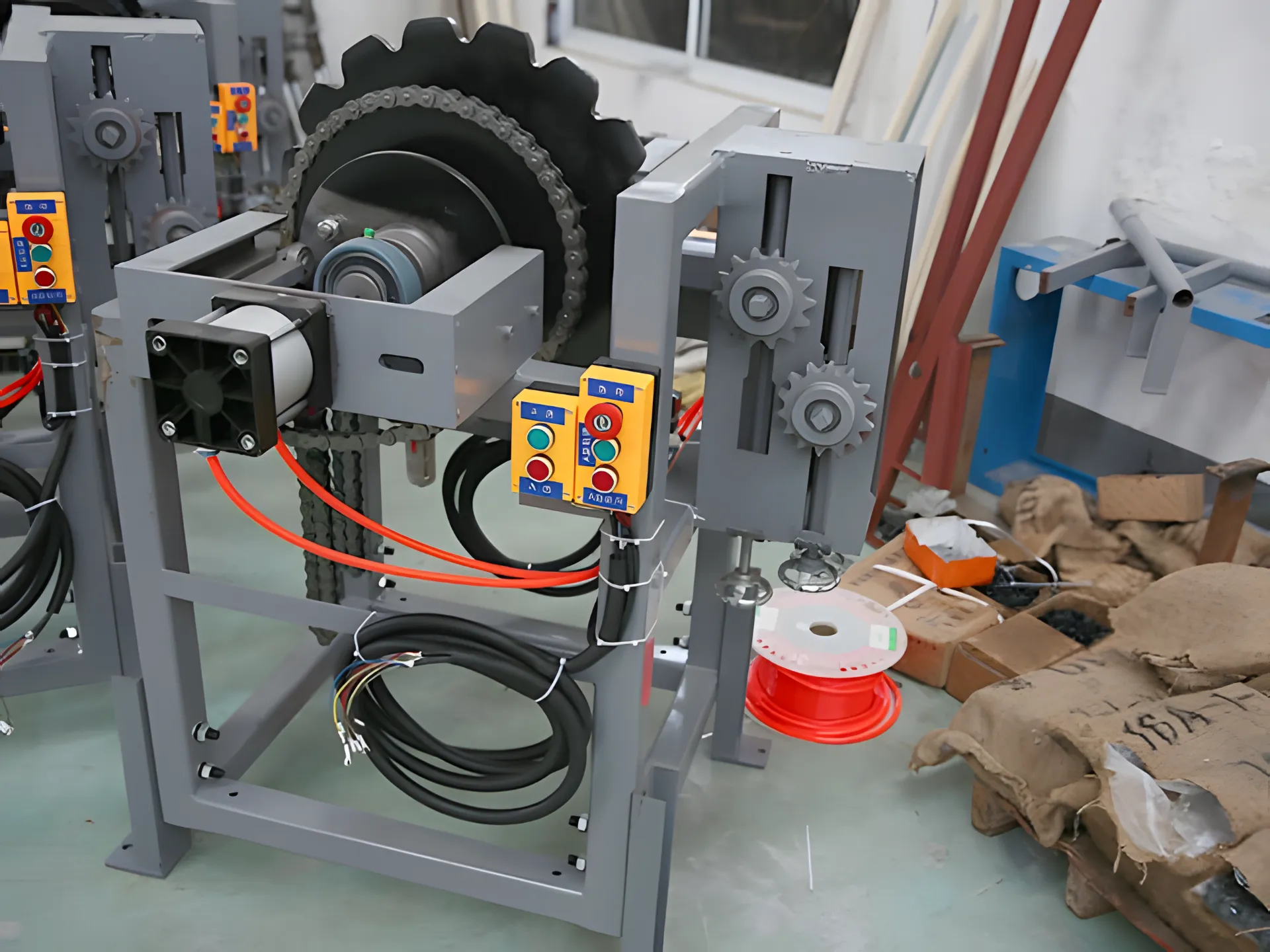

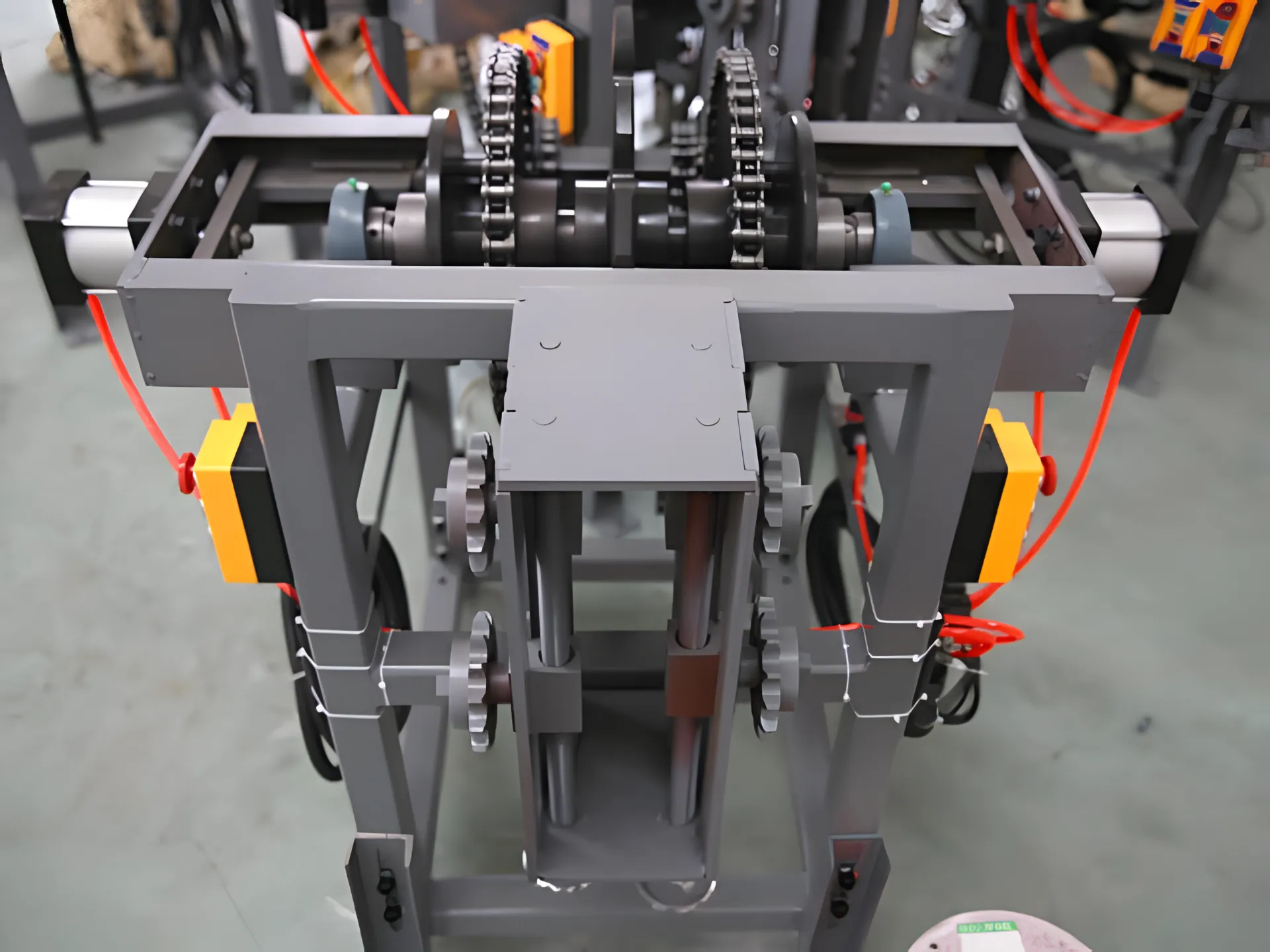

Transmission System:

-

Gears: Use robust gears with appropriate ratios to match motor speed to equipment requirements. Consider helical gears for quieter operation and smoother power transmission.

-

Belts and Pulleys: Offer flexibility and ease of maintenance. Choose belts with high tensile strength and wear resistance.

-

Chains and Sprockets: Suitable for high-torque applications. Ensure proper lubrication and chain tensioning.

-

-

Frame Construction:

-

Material: Use sturdy materials like steel or aluminum for structural integrity and durability.

-

Design: Ensure rigidity and stability to minimize vibrations and noise.

-

Mounting: Provide secure mounting points for the motor, gearbox, and downstream equipment.

-

-

Safety Features:

-

Guards: Install guards around moving parts to prevent accidents.

-

Emergency Stop: Incorporate an easily accessible emergency stop button.

-

Interlocks: Implement interlocks to prevent operation if safety guards are not in place.

-

-

Maintenance Access:

-

Design for easy access to lubrication points, belts, and other components requiring regular maintenance.

-

Consider incorporating quick-release mechanisms for faster disassembly and reassembly.

-

3. Additional Features:

-

Variable Speed Drive (VSD): Allows for precise control of motor speed and torque, optimizing production efficiency and reducing energy consumption.

-

Torque Limiter: Protects the drive system from overload by disengaging when torque exceeds a preset limit.

-

Cooling System: May be necessary for high-power applications to prevent overheating.

4. Customization:

The PTO frame design should be customized to the specific requirements of the glove production line. Factors to consider include:

-

Layout: The arrangement of equipment and available space.

-

Production Volume: The desired output rate.

-

Glove Type: The specific type of gloves being produced (e.g., surgical, industrial, disposable).

-

Automation Level: The degree of automation desired in the production process.

5. Collaboration:

It is crucial to collaborate with experienced engineers and equipment manufacturers to ensure the PTO frame is designed and built to meet the specific needs of the glove production line.

Rumtoo Machinery

Rumtoo Machinery Tiedustele nyt

Tiedustele nyt