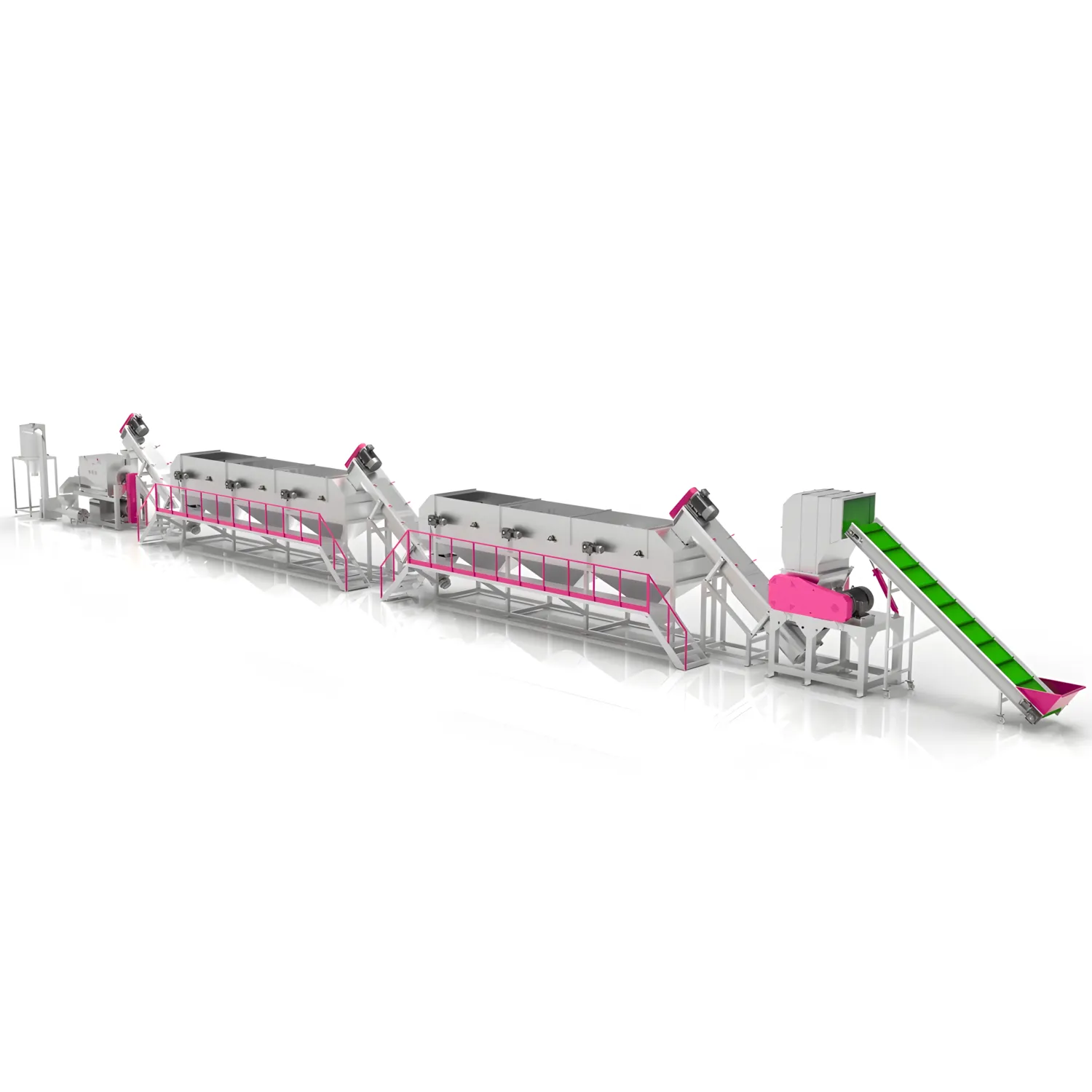

Plastic Film Shredding and Densifying Machine for Recycling Line

Our Plastic Film Shredding and Densifying Machine offers an integrated solution, first shredding film into <50mm pieces, then compacting them into dense Ø8-15mm pellets for cost-effective transport and efficient downstream processing.

描述

The Ultimate Solution for Film Recycling

Advanced Plastic Film Densifier and Shredder

Our integrated plastic film densifier & shredder (also known as a film agglomerator/compactor) transforms bulky PE/PP films into dense, easy‑to‑handle pellets. Drastically cut storage and transport costs while optimizing your entire recycling workflow.

Why Densify Plastic Film?

The Economic & Operational Benefits of Compaction Explore our Plastic Film Washing Line

Reduce Transport Costs

Loose film is mostly air. Our densifier increases bulk density from ~50 kg/m³ to over 350 kg/m³. Transport 5-7 times more material in the same truck space, dramatically cutting logistics expenses.

Optimize Storage Space

Compacted film pellets require significantly less storage space in your facility, freeing up valuable floor area for other operations and improving on-site logistics.

Improve Pelletizing Efficiency

Dense, uniform pellets provide a stable and consistent feed for the next stage, improving throughput and final granule quality.

Two-Stage Process: From Loose Film to Dense Pellets

High-Efficiency Shredding

An intelligent feeding system controls the input of plastic film into the shredder. Adjustable rotating blades efficiently shred the material into uniform pieces (approx. 50 mm). An integrated dust removal system helps manage dust and reduce noise during this process.

High-Density Densification

The shredded plastic film is then conveyed to the densifier. This unit presses and heats the material into dense pellets (Ø8–15 mm) with high bulk density. This densification process makes the recycled plastic more compact and economical for transport. Intelligent temperature control prevents overheating.See our Plastic Pelletizing Line

Key Features & Advantages

Integrated Shredding & Densifying

Combines two crucial processes into one efficient unit for streamlined film recycling.

High Bulk Density Output

Produces compact, dense pellets that significantly reduce transport costs and improve handling.

Intelligent Feeding & Control

Smart systems for material input and temperature control ensure consistent and safe operation.

Dust & Noise Reduction

Integrated dust removal and noise reduction features contribute to a better working environment.

Durable SKD11 Knives

Shredder equipped with high-quality SKD11 blades for long service life and efficient cutting.

CE Certified & Safe

Built with advanced safety measures and CE certification for reliable and secure operation.

Ideal for a Wide Range of Materials

Our plastic film densifier is engineered to handle various soft plastics, making it a versatile asset for any recycling facility for PE/PP film recycling.

Technical Specifications

Model Parameters

| Model | Capacity (kg/h) | Power |

|---|---|---|

| RTM-200 | 200 | 160–200 kW |

| RTM-500 | 500 | 200–240 kW |

| RTM-1000 | 1,000 | 400–450 kW |

General Specs

| Item | Value |

|---|---|

| Voltage | 380V, 50Hz, 3‑phase |

| Standard Power | 45 kW (varies by model) |

| Standard Capacity | 300–500 kg/h (varies by model) |

| Shredding Size | <50 mm |

| Densified Pellet Size | Ø8–15 mm |

Product Showcase

Please replace placeholders with actual product images.

Revolutionize Your Plastic Film Recycling

Contact our experts today to get the latest prices, lead times, and learn how our Plastic Film Densifying and Shredding Machine can transform your recycling line.

Frequently Asked Questions

What types of plastic film is this machine suitable for?

This machine is designed primarily for PE (Polyethylene) and PP (Polypropylene) films, including agricultural film, industrial packaging film, stretch film, and other soft plastic films.

How does densification benefit the recycling process?

Densification (or agglomeration) significantly increases the bulk density of the shredded film, making it much more compact. This reduces storage space, lowers transportation costs, and improves the stability and efficiency of feeding into subsequent machines like pelletizers.

Can the densified pellets be fed directly into a pelletizer?

Yes, absolutely. The dense, uniform pellets are ideal for direct and stable feeding into a plastic extruder for the final pelletizing stage, leading to higher quality output.

What is the difference between a densifier and an agglomerator?

The terms ‘densifier’, ‘compactor’, and ‘agglomerator’ are often used interchangeably for this type of machine. They all refer to the process of compacting loose, light plastic film into a denser, heavier form.

What is the warranty on this machine?

All our recycling machines, including the Plastic Film Shredding and Densifying Machine, come with a 1-year limited warranty covering manufacturing defects and ensuring reliable operation.