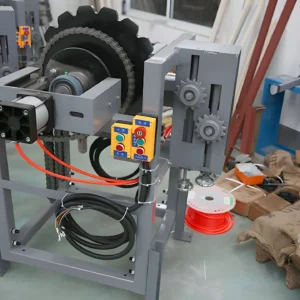

Automatic Counting Machine for PVC/Nitrile Glove Production Line

Fully automatic glove counting and stacking system that syncs with your line to increase throughput, reduce labor, and ensure accurate counts.

描述

Automatic Glove Counting & Stacking System

Boost glove line throughput with a fully automatic system that grabs, stacks, and counts half-off gloves—synchronized to your production rhythm, reducing labor and eliminating miscounts.

Quick Highlights

- Motor-synced grabbing & stacking

- PLC intelligent counting (detects empty molds)

- Automated folding, stacking, transport

- Quiet operation & safety-centric design

Technical Specifications

- Dimensions: Rear frame: 450×400×620 mm; Conveying frames: 1030×500×620 mm and 1330×500×620 mm

- Motors: 2 pcs per set, total power 800W

- Power Supply: 220V (customizable)

How It Works

Precise Glove Handling

Manipulator clamps gently grab individual half-off gloves from molds without damage.

Synchronized Operation

Grabbing and stacking speed matches the line pace to keep flow continuous and smooth.

Automated Counting & Stacking

Every N gloves are folded, stacked, and conveyed with real-time counting that excludes empty molds.

Key Benefits

Efficiency: Automates counting and stacking so staff can be redeployed.

Labor Savings: Reduces headcount with hands-off operation.

Accuracy: PLC logic filters empty molds to avoid false counts.

Quiet & Safe: Low noise operation (<40dB) with built-in safety features.

FAQ

A: Yes. Intelligent PLC control distinguishes and skips empty molds to keep counts accurate.

A: Designed for seamless sync, it integrates without major reconfiguration, aligning with your line’s timing.

A: Yes. You can configure how many gloves (N) are folded and stacked before delivery.

A: Routine clamp inspection and system diagnostics; modular design keeps servicing fast.

A: Yes. Clamps and timing parameters are adjustable for a range of glove types and dimensions.

Optimize your glove line with automated counting, stacking, and real-time accuracy.