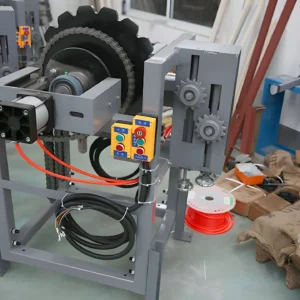

Automatic Stripping Machine for Nitrile Glove Production Line

Automated stripping system for nitrile glove lines that eliminates manual demolding—synchronized operation, no extra drive motors, higher throughput, and consistent quality.

描述

Motor-Free, Synchronized Glove Demolding for Maximum Throughput

Replace slow, manual glove removal with a synchronized, motor-free stripping system that integrates seamlessly into your line—delivering faster demolding, consistent quality, and lower operating costs.

Core Capabilities

- Synchronized stripping without additional drive motors.

- Integrated sequence: mold fitting, blowing, flanging, flaring, outward movement, and glove removal.

- Smooth, quiet operation for continuous production.

Key Benefits

- Faster demolding increases throughput.

- Lower labor requirement—reduce operators per line.

- Consistent glove quality with minimal waste.

- Reduced cost per unit through automation.

Motor-Free Sync: Eliminates separate drive components by leveraging line timing for seamless stripping.

All-in-One Flow: Combines multiple downstream removal steps into a single fluid action, reducing cycle complexity.

Upgrade to automated, synchronized glove stripping for higher output and lower costs.

Frequently Asked Questions

Q: Does this system require a separate motor?

A: No. It operates in sync with your existing production line timing—eliminating the need for additional drive motors while maintaining precise stripping action.

Q: Can it be integrated into an existing nitrile glove line?

A: Yes. The design is meant for seamless retrofit or new-line integration, aligning with mold movement and downstream processes without disrupting cycle flow.

Q: How does it impact labor and yield?

A: Automated stripping reduces operator dependency and lowers labor cost, while consistent demolding minimizes defects—resulting in higher effective yield.

Q: Is the operation noisy or disruptive?

A: No. The system is engineered for smooth, quiet operation, preserving a stable production environment without excessive vibration or sound.

Q: What kind of support or setup assistance is available?

A: We offer integration support, including alignment tuning, startup assistance, and training to ensure the machine syncs properly and delivers immediate gains.