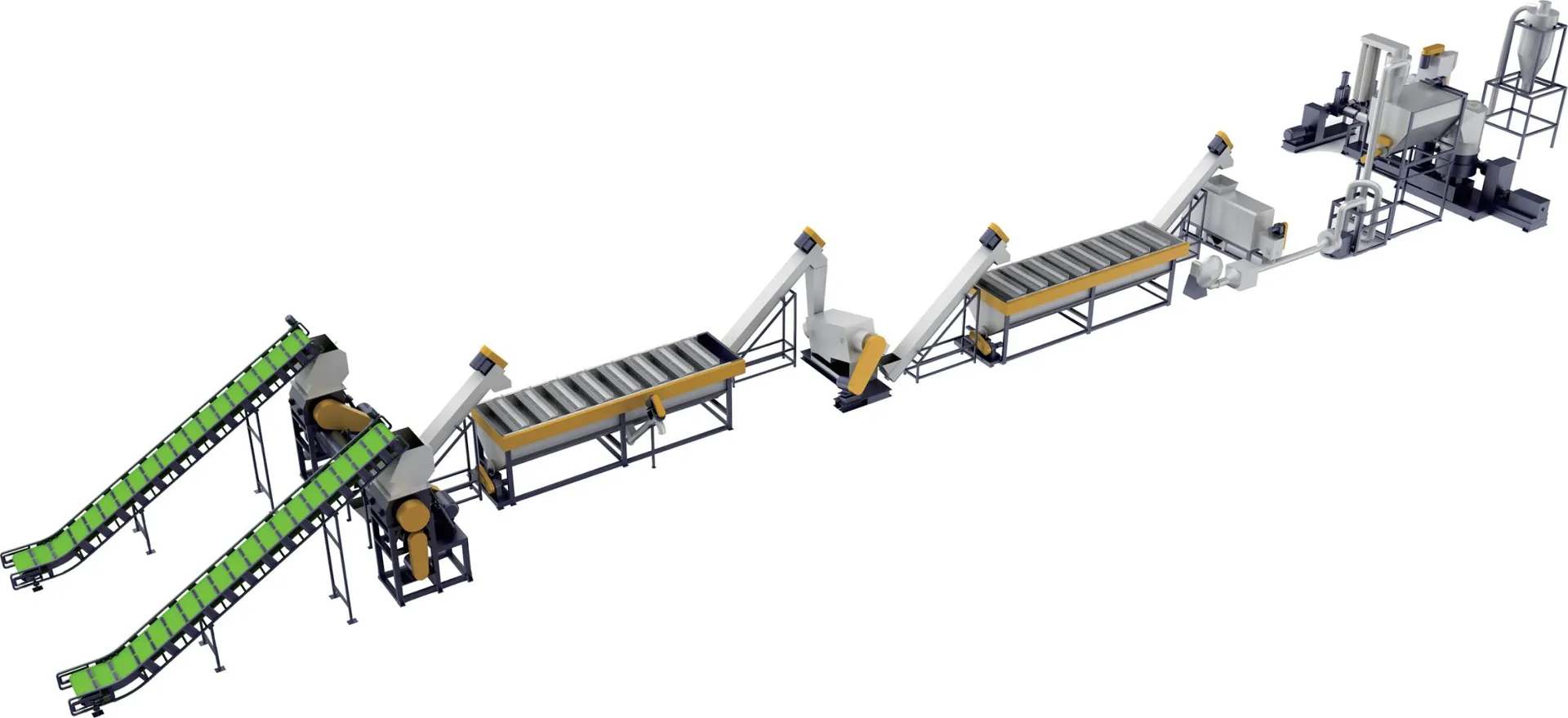

High-Performance Plastic Waste Recycling Machine

A Plastic Waste Recycling Machine, also known as an industrial waste recycling system, is a series of equipment designed to transform used plastic items—like bottles, films, and containers—into high-quality raw materials (pellets). These pellets can then be used to manufacture new plastic products, closing the loop in the circular economy.

Get a Quote for Your ProjectWe Handle a Wide Range of Plastic Materials

PET / PETE (Polyethylene Terephthalate)

Commonly found in beverage bottles and food jars. We provide specialized PET bottle washing and pelletizing lines.

HDPE (High-Density Polyethylene)

Used for milk jugs, detergent bottles, and pipes. Our equipment effectively processes this rigid plastic.

PVC (Polyvinyl Chloride)

Found in window frames, pipes, and packaging film. We have solutions to handle the specific challenges of PVC recycling.

LDPE / PP (Low-Density Polyethylene & Polypropylene)

Agricultural films, woven bags, and packaging materials. Our film recycling lines include powerful washing and drying stages.

ABS / PS (Acrylonitrile Butadiene Styrene & Polystyrene)

Rigid plastics from electronics, car parts, and toys. Our crushers and granulators handle tough materials with ease.

Other Plastics

We can also customize industrial waste recycling systems for other plastics like PC, nylon, and mixed plastic waste.

How Our Waste Recycling Equipment Works: A 4-Step Process

1. Sorting & Crushing

Waste plastics are first sorted to remove contaminants. Then, industrial shredders and crushers reduce the material into smaller, uniform flakes for easier processing.

2. Washing & Cleaning

The flakes undergo an intensive cleaning process using friction washers and float-sink tanks to remove dirt, labels, and glue, ensuring high purity.

3. Drying

A dewatering machine and thermal drying system efficiently remove moisture. This step is critical for producing high-quality, void-free final pellets.

4. Pelletizing

Clean, dry flakes are melted, filtered, and extruded into spaghetti-like strands, which are then cut into uniform pellets, ready for reuse in manufacturing.

Our Solutions Serve Diverse Industries

Recycling Companies

Process post-consumer and industrial plastic waste efficiently, turning low-value material into a profitable commodity.

Manufacturing Plants

Recycle in-house production scrap (e.g., rejects, trimmings) to reduce waste disposal fees and raw material costs.

Government & Municipalities

Implement effective waste management programs and contribute to local circular economy goals with our reliable systems.

Explore Our Plastic Recycling Machine Series

Plastic Crusher

View Size Reduction

Plastic Washing Line

View Washing Systems

Pelletizing Line

View Pelletizers

Drying Machine

View AuxiliariesAdvantages of Our Industrial Waste Recycling Systems

High Automation

Our integrated lines feature intelligent controls for streamlined operation, reducing labor costs and human error.

Energy Saving Design

Equipped with high-efficiency motors and optimized designs to lower power consumption and operational expenses.

High Processing Capacity

Engineered for high throughput, our machines can process from 300kg/h to over 2000kg/h, meeting various production demands.

Robust and Durable

Constructed with wear-resistant materials to ensure long-term stability and reliability, even under 24/7 operation.

Superior Pellet Quality

Advanced washing and degassing technologies produce clean, high-quality pellets that command a higher market price.

Turnkey Solution & Support

We provide a complete service package, from plant design and installation to training and after-sales support.

Frequently Asked Questions

What is the lead time for a complete plastic recycling line?

The lead time typically ranges from 60 to 90 days, depending on the complexity and customization of the waste recycling equipment. We will provide a precise timeline with our formal quotation.

Can you customize the machine based on my raw material and output requirements?

Absolutely. Customization is our specialty. We will analyze your input material (e.g., contamination level, plastic type) and your desired output capacity to design a perfectly tailored industrial waste recycling system for you.

Do you offer installation and training services?

Yes, we provide comprehensive turnkey solutions. This includes sending our engineers to your site for installation, commissioning the line, and providing thorough training for your operators to ensure smooth and efficient operation.

What is your warranty policy?

All our plastic waste recycling machines and complete lines come with a standard one-year warranty. This covers any manufacturing defects and ensures the quality of our equipment. We also provide lifelong technical support and spare parts supply to guarantee the long-term success of your operation.

Request a Custom Quote

Ready to turn plastic waste into profit? Tell us about your recycling needs—plastic type, source, and desired capacity—and our experts will get back to you with a tailored solution and a no-obligation quote.