In today’s fast-evolving recycling industry, efficiency, consistency, and material adaptability are more crucial than ever. At Rumtoo Machine, we understand the unique challenges faced by manufacturers and industrial recyclers. One technological solution that is transforming the landscape of plastic recycling is the Twin-Screw Extruder—a powerful, versatile system offering unmatched benefits for reclaiming and reprocessing plastic materials.

What is a Twin-Screw Extruder?

A Twin-Screw Extruder is an advanced plastic processing machine featuring two intermeshing screws rotating inside a barrel. Unlike single-screw extruders, twin-screw systems enable more effective mixing, compounding, and devolatilisation—key factors when working with contaminated or mixed plastic waste streams.

Rumtoo Machine’s extruders are engineered for superior control, throughput, and customisation, making them ideal for handling today’s demanding plastic recycling processes.

Key Applications in Plastic Recycling

1. Processing Mixed and Contaminated Plastics

Twin-screw extruders are especially suitable for handling complex plastic mixtures such as post-consumer or post-industrial waste. At Rumtoo Machine, we integrate venting systems and degassing ports that effectively remove volatiles and moisture—ensuring consistent product quality.

2. Compounding Recycled Materials

Combining recycled polymers with fillers, fibres, or additives is critical for value-added manufacturing. The design of twin-screw extruders allows precise ingredient metering, uniform distribution, and enhanced mechanical properties in the final product.

3. Pelletising and Repelletising

Rumtoo Machine’s twin-screw systems are optimised for pelletising recycled plastics into reusable granules. Our systems maintain excellent pellet uniformity, an essential requirement for high-end applications like injection moulding or extrusion-grade products.

Advantages of Twin-Screw Extruders in Plastic Recycling

1. Superior Mixing and Homogenisation

The intermeshing screw elements of a twin-screw extruder promote high shear and intensive mixing—vital for achieving uniform polymer blends.

2. Higher Throughput

Rumtoo Machine’s twin-screw systems offer enhanced throughput due to more efficient melting and pressure generation, resulting in faster processing and higher yields.

3. Excellent Material Flexibility

Whether recycling PE, PP, PET, or engineering plastics, our twin-screw extruders are designed to handle a broad range of materials without compromising on quality or output.

4. Effective Degassing

Our extruders include strategically placed venting zones to eliminate gases, moisture, and low-molecular-weight compounds, ensuring a stable and reliable output.

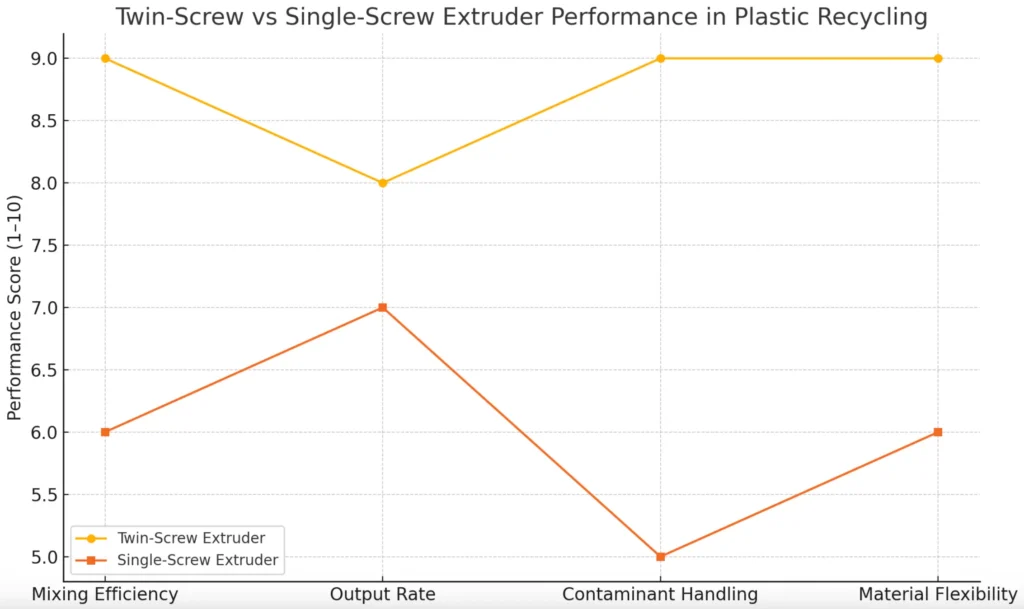

Comparison of Twin-Screw vs Single-Screw Extruders: Rumtoo Machine data based on field performance testing.

Why Choose Rumtoo Machine?

With over a decade of experience in recycling machinery, Rumtoo Machine stands as a trusted partner in delivering tailored extruder solutions that align with your operational goals. Our systems combine German engineering precision with cost-effective manufacturing, offering exceptional ROI and performance.

From design consultation to installation and after-sales support, our expert team ensures seamless integration into your production line.

Frequently Asked Questions (FAQ)

Q1: What types of plastics can a twin-screw extruder recycle?

A: Rumtoo Machine’s twin-screw extruders can recycle a wide range of thermoplastics including PE, PP, PET, ABS, PS, and even engineering-grade plastics.

Q2: Is it possible to add fillers or additives during extrusion?

A: Yes, twin-screw extruders are specifically designed for compounding and can incorporate additives, colourants, and reinforcing agents inline.

Q3: How does a twin-screw extruder handle moisture in the feedstock?

A: Our systems feature efficient degassing zones that remove moisture and volatiles, making them ideal for wet or contaminated inputs.

Q4: How do I determine the right extruder configuration for my recycling needs?

A: Our team at Rumtoo Machine offers free technical consultations to recommend the best extruder model and configuration based on your material type and processing goals.

Ready to Boost Your Recycling Efficiency?

Discover how Rumtoo Machine’s twin-screw extruder technology can transform your plastic recycling operations. Contact us today to discuss your needs or request a quote. Let’s build a cleaner, more efficient future—together.