Introduction

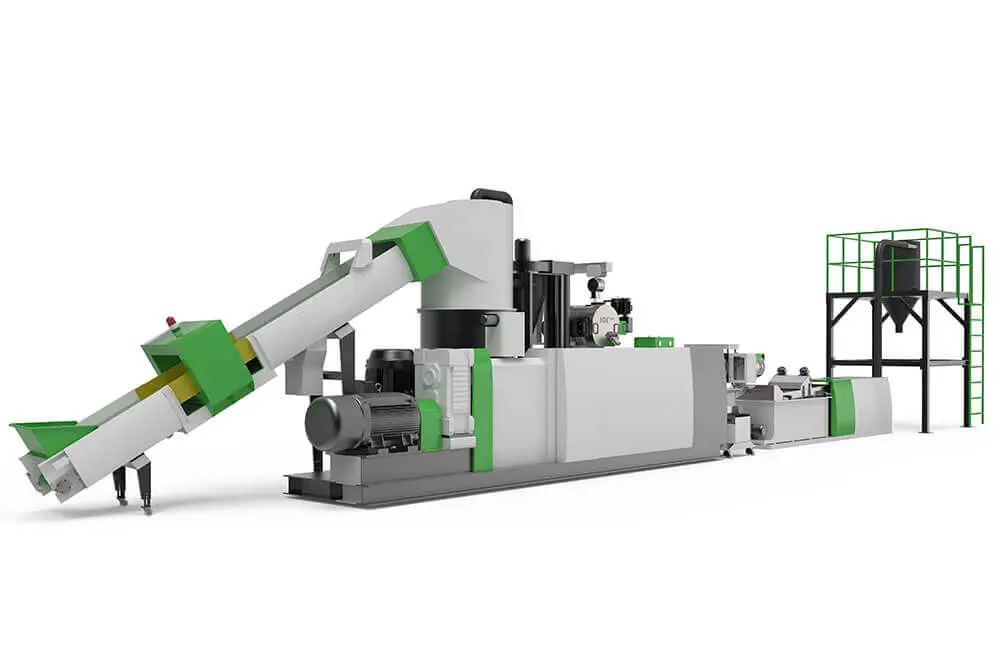

In today’s fast-moving recycling industry, compaction recycling pelletizers are transforming the way plastic waste is processed. By combining compaction, extrusion, and pelletizing in one integrated system, these machines efficiently convert plastic film, bag, and fiber waste into high-quality reusable granules.

At Rumtoo, we provide advanced compaction recycling systems engineered for stability, energy savings, and top-grade output—helping recyclers maximize productivity and sustainability.

The Technology Behind Compaction Recycling Granulators

A compaction recycling granulator integrates multiple processes into one streamlined operation:

- Compacting (Agglomeration) – Plastic waste is compressed and preheated in the compactor to remove moisture and air.

- Extrusion – The pre-treated material is fed into the extruder, where it is melted and homogenized under controlled temperature and pressure.

- Pelletizing – The molten plastic is cut into uniform granules using a precision pelletizing system.

This integrated approach eliminates the need for separate pre-processing equipment and improves overall process stability and output quality.

For flexible packaging and film waste, these systems work exceptionally well when paired with BOPP pelletizing technology.

Learn more about our BOPP Plastic Pelletizing System, designed to handle oriented polypropylene films with outstanding efficiency.

Benefits of Using Compaction Recycling Granulators

1. High Efficiency

The system can process a wide range of materials—from thin films and woven bags to synthetic fibers—handling capacities from small-scale operations to industrial-level recycling plants.

2. Superior Output Quality

Compaction granulators produce dense, uniform, and glossy granules that can be reused for film blowing, injection molding, or extrusion processes without loss of performance.

3. Energy Saving

Integrated heating and material transfer reduce energy loss, while the single-stage process lowers power consumption compared with traditional multi-step systems.

4. Versatility

They are suitable for recycling HDPE, LDPE, PP, PET, and BOPP films, making them ideal for mixed plastic recovery and closed-loop production environments.

5. Space-Saving Design

Combining compaction, extrusion, and pelletizing in one unit reduces equipment footprint and simplifies plant layout, ideal for facilities with limited space.

Applications in Recycling and Waste Management

Plastic Film and Bag Recycling

Perfect for recycling plastic films, stretch wrap, and shopping bags, converting them into reusable granules for manufacturing.

Fiber Recycling

Highly effective for synthetic fiber recycling, supporting sustainability in the textile and nonwoven industries.

Packaging Material Recycling

Excellent for recycling flexible packaging materials—including BOPP, PE, and multilayer films—supporting a circular packaging economy.

Consumer Goods Manufacturing

The recycled granules can be used to produce a wide range of products such as household goods, toys, or construction materials.

Why Choose Rumtoo Compaction Recycling Systems

Rumtoo’s compaction pelletizers combine reliability, innovation, and energy efficiency—delivering exceptional value for recycling professionals.

Our systems feature:

- Advanced temperature and pressure control for consistent performance

- Robust components and wear-resistant materials for long service life

- Intelligent automation and easy maintenance

- Custom configurations to match your production capacity and material types

With Rumtoo, you get more than a machine—you gain a partner committed to long-term recycling success.

Conclusion

The compaction recycling pelletizer plays a vital role in the modern recycling landscape, providing efficient, high-quality, and versatile solutions for plastic waste transformation.

For recyclers processing oriented films and flexible packaging, our BOPP Plastic Pelletizing System offers the perfect complement—ensuring uniform pellets, reduced energy consumption, and superior output quality.

Choose Rumtoo to power your recycling line with proven technology, smart design, and dependable performance.