Choosing the right plastic recycling machine is crucial for any business looking to implement sustainable practices. With various types of machines available, each offering different features and capabilities, it’s important to understand which one fits your needs best. This article provides a comparative overview of the main types of plastic recycling machines, highlighting their features, costs, and suitability for different scales of operation.

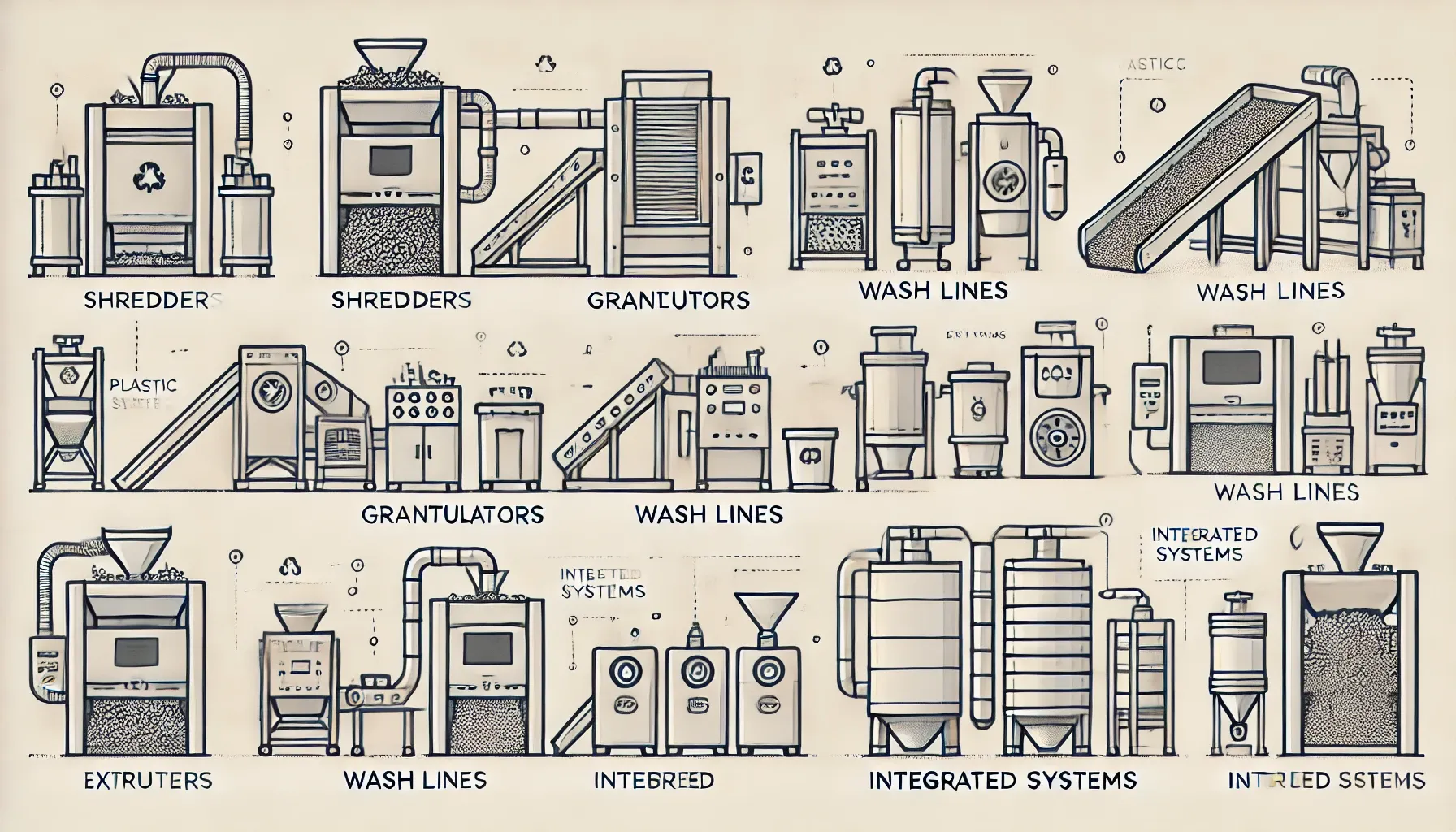

Types of Plastic Recycling Machines

1. Shredders

Features

- Function: Shredders break down plastic waste into smaller pieces, making it easier to process further.

- Capacity: Available in various capacities to handle different volumes of plastic waste.

- Technology: Some models include advanced features like automated feeding and dust suppression.

Costs

- Price Range: $5,000 to $50,000 depending on capacity and features.

- Maintenance: Generally low, with periodic blade replacements required.

Suitability

- Small to Medium Businesses: Ideal for businesses with moderate amounts of plastic waste.

- Pre-Processing Stage: Best used as the initial step in a comprehensive recycling process.

2. Granulators

Features

- Function: Granulators further reduce shredded plastic into fine granules.

- Capacity: Suitable for continuous operation with high throughput.

- Technology: Often includes noise reduction features and energy-efficient motors.

Costs

- Price Range: $10,000 to $70,000 depending on size and capabilities.

- Maintenance: Moderate, with regular inspection and cleaning needed.

Suitability

- Medium to Large Businesses: Perfect for operations requiring fine granules for recycling or resale.

- Secondary Processing: Typically used after shredders in the recycling process.

3. Washing Lines

Features

- Function: Washing lines clean plastic waste to remove contaminants like labels and residues.

- Capacity: Designed to handle large volumes with continuous washing and drying stages.

- Technology: Advanced models include automatic sorting and drying systems.

Costs

- Price Range: $20,000 to $100,000 based on complexity and capacity.

- Maintenance: High, with frequent cleaning and part replacements.

Suitability

- Large-Scale Operations: Essential for businesses processing high volumes of plastic waste.

- Pre-Processing Stage: Used before granulation to ensure clean material.

4. Extruders

Features

- Function: Extruders melt and re-form plastic granules into new products or pellets.

- Capacity: High-capacity machines can process several tons of plastic per day.

- Technology: Equipped with advanced temperature control and automated feeding systems.

Costs

- Price Range: $30,000 to $200,000 depending on size and features.

- Maintenance: High, with regular checks and component replacements necessary.

Suitability

- Large Businesses and Manufacturers: Ideal for producing recycled plastic products.

- Final Processing Stage: Used after shredding, granulating, and washing stages.

5. Integrated Systems

Features

- Function: Combine shredding, washing, and granulating into one system.

- Capacity: Varies, but designed for seamless integration and continuous processing.

- Technology: Highly automated with minimal manual intervention required.

Costs

- Price Range: $50,000 to $300,000 based on capacity and integration level.

- Maintenance: Moderate to high, with the need for regular system checks.

Suitability

- Comprehensive Solutions: Best for businesses looking to streamline their recycling process.

- Various Scales: Suitable for small to large operations depending on system size.

Making the Right Choice

When selecting a plastic recycling machine, consider the following factors:

- Volume of Waste: Choose a machine that matches your waste output.

- Type of Plastic: Ensure the machine can handle the specific types of plastic you process.

- Budget: Balance initial investment with long-term maintenance costs.

- Space Availability: Make sure you have sufficient space for installation and operation.

- Future Needs: Consider potential business growth and scalability of the machine.

Conclusion

Selecting the right plastic recycling machine depends on your business’s specific needs, including the type and volume of plastic waste, budget, and operational scale. By understanding the features, costs, and suitability of different machines, you can make an informed decision that supports your sustainability goals and operational efficiency.