Desktop Filament Extrusion System

Desktop 3D Filament Extruder Maker

Transform plastic pellets or waste into high-quality, precision 3D printer filament on demand.

Request a QuoteYour In-House Filament Factory

Gain full control over your 3D printing materials with our professional-grade extrusion system. Reduce costs, recycle waste, and innovate without limits.

Drastic Cost Savings

Lower your material expenses by up to 80% by using raw pellets instead of pre-made filament spools.

Sustainable Production

Create a circular economy in your workspace by recycling failed prints and plastic scrap into new, usable filament.

Material Innovation

Experiment with custom colors, blends, and composite materials to unlock new application possibilities.

Ideal for a Range of Applications

Our filament extruder empowers professionals across various industries to achieve their goals.

R&D and Material Labs

Develop and test novel composite materials and custom polymer blends with full control over the extrusion process.

Universities & Education

An invaluable hands-on tool for teaching material science, engineering principles, and sustainable practices.

Small-Batch Manufacturing

Produce custom-colored or specialized filaments on-demand for rapid prototyping and short-run production parts.

Sustainability Hubs

Turn sorted plastic waste into valuable, high-quality filament, creating a true circular economy and reducing environmental impact.

See It In Action

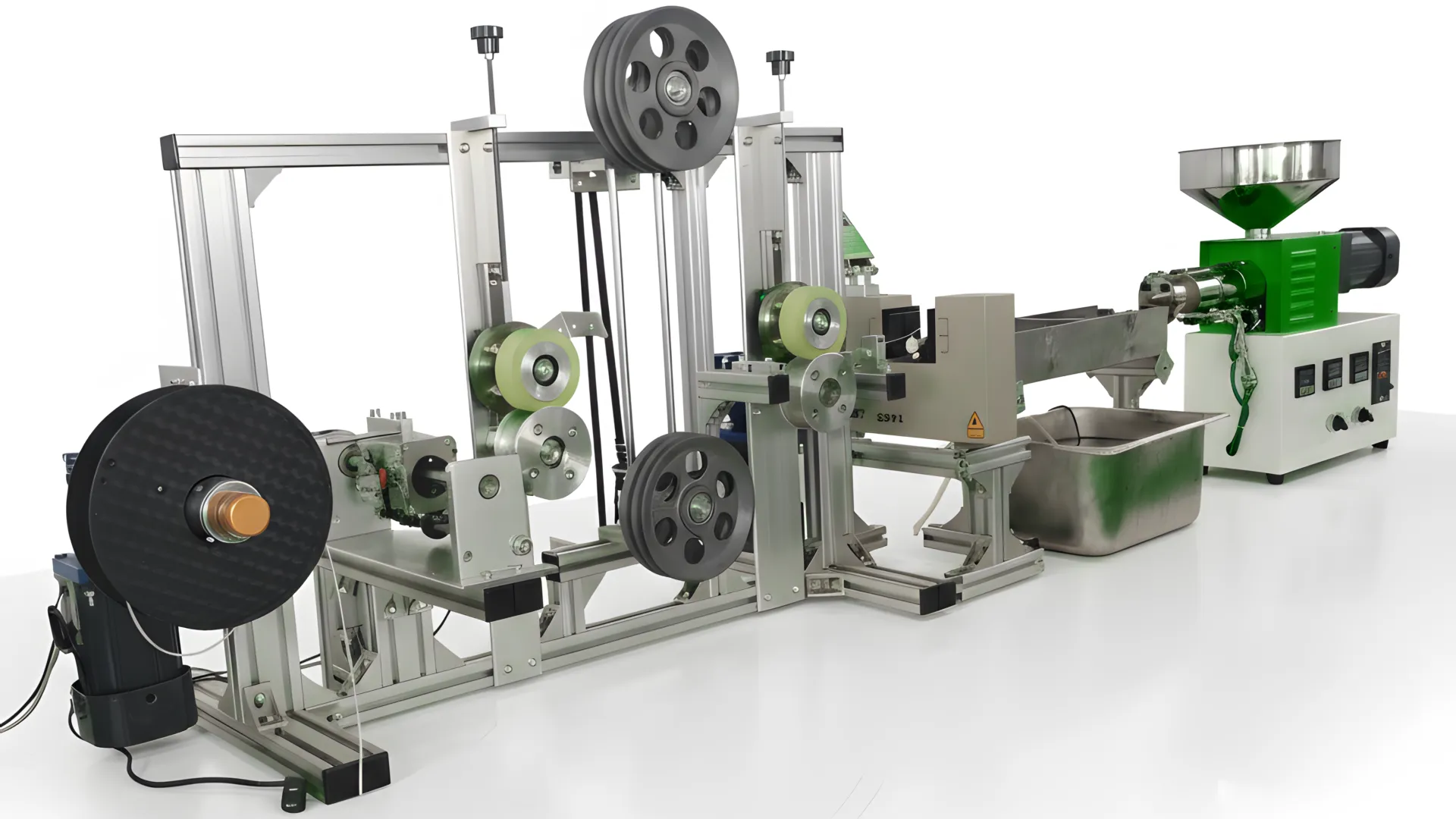

Product Gallery

Explore the robust construction and precision components of our filament extruder.

Our Advanced 8-Step Extrusion Process

From raw material to spooled filament, every stage is engineered for precision, consistency, and reliability.

1. Extruder

The core of the production line. Our precision screw and multi-zone heating system melts and plasticizes raw materials into a homogenous molten stream, extruded through a hardened steel nozzle.

2. Circulating Cooling Water Tank

The hot filament is immediately immersed in a circulating cold water bath, rapidly solidifying it to ensure a perfectly round cross-section and stable structure.

3. Laser Diameter Gauge (Optional)

A high-precision, dual-axis laser micrometer provides real-time, non-contact diameter measurement, feeding data to the haul-off system to guarantee a tolerance of ±0.03mm.

4. Haul-off Wheel

A digitally controlled, high-traction wheel pulls the filament at an exceptionally stable speed. This works in tandem with the extruder and laser gauge to control the final filament diameter with utmost precision.

5. Dancer Wheel

This tensioning system acts as a buffer, maintaining consistent tension between the puller and the winder. It prevents stretching and ensures accurate length counting and neat spooling.

6. Meter Counter

An integrated digital counter accurately measures the length of the produced filament, allowing for precise spooling according to your specified length.

7. Automatic Traverse Device

The automated traversing guide moves from side to side, laying the filament perfectly on the spool. This ensures a neat, tangle-free wind every time.

8. Winder

The final stage. The winder automatically spools the finished, high-quality filament onto a standard reel, ready for immediate use, storage, or packaging.

Technical Specifications

Standard parameters are listed below. Customization is available to meet your specific requirements.

| Screw Diameter | 25mm |

| Design Capacity | 0.1 – 2 KG/h |

| Machine Dimensions | 0.76 x 0.2 x 0.5 m |

| Motor Power | 250W |

| Voltage | 220V (customizable) |

| Heating Temperature | Room Temp to 350°C |

| Screw & Barrel Material | 38CrMoAl (Nitrided Steel) |

Frequently Asked Questions

Is it cheaper to make your own 3D filament?

Absolutely. Raw plastic pellets cost significantly less than commercial filament spools—often up to 80% cheaper. For any organization that prints regularly, the cost savings on materials alone provides a rapid return on investment.

What plastics can I use in a filament extruder?

Our extruders are designed to work with a wide range of common thermoplastics, including PLA, PETG, and ABS. Furthermore, they are excellent for processing clean, shredded plastic waste from failed prints, turning your scrap into valuable material.

How do you ensure the filament has a consistent diameter?

This is achieved through a closed-loop control system. The optional Laser Diameter Gauge constantly measures the filament, and this data is fed to the Haul-off Wheel, which automatically adjusts its speed. This system is the key to producing professional-grade filament with tight tolerances (e.g., ±0.03mm).

Can I create custom-colored or composite filaments?

Yes. This is one of the main advantages. You can easily mix colorant masterbatch with virgin pellets to create custom colors. You can also experiment by adding other materials, like carbon fiber or wood dust, to develop unique composite filaments for specific applications.

Is a desktop filament extruder worth it for a small business or lab?

For small businesses, R&D labs, and educational institutions, a desktop extruder is a strategic investment. It drastically cuts material costs, enables rapid prototyping with custom materials, provides supply chain independence, and serves as a powerful tool for recycling and sustainability initiatives.

Trusted by Innovators

See what our clients have to say about the impact of our technology on their work.

“The cost savings are incredible. We reduced our filament budget by over 70% in the first quarter. The machine paid for itself in months.”

“Being able to create custom composite filaments on-demand has accelerated our prototyping cycle by weeks. The precision and reliability are top-notch.”

“As an educational institution, this extruder is an invaluable tool for both teaching sustainable practices and for student projects. It’s robust and easy to use.”

Ready to Revolutionize Your 3D Printing?

Contact our team of experts to learn how the Desktop 3D Filament Extruder Maker can integrate into your workflow and accelerate your innovation.

Get a Custom Quote Today