Thermal Dryer System Closed-loop heat for gentle film drying

A fully insulated plenum, variable-speed fans, and indirect heat reclaim pull moisture from washed film without scorching, so flakes leave the tunnel below 2% moisture and ready for densifying or pelletizing with minimal energy carryover.

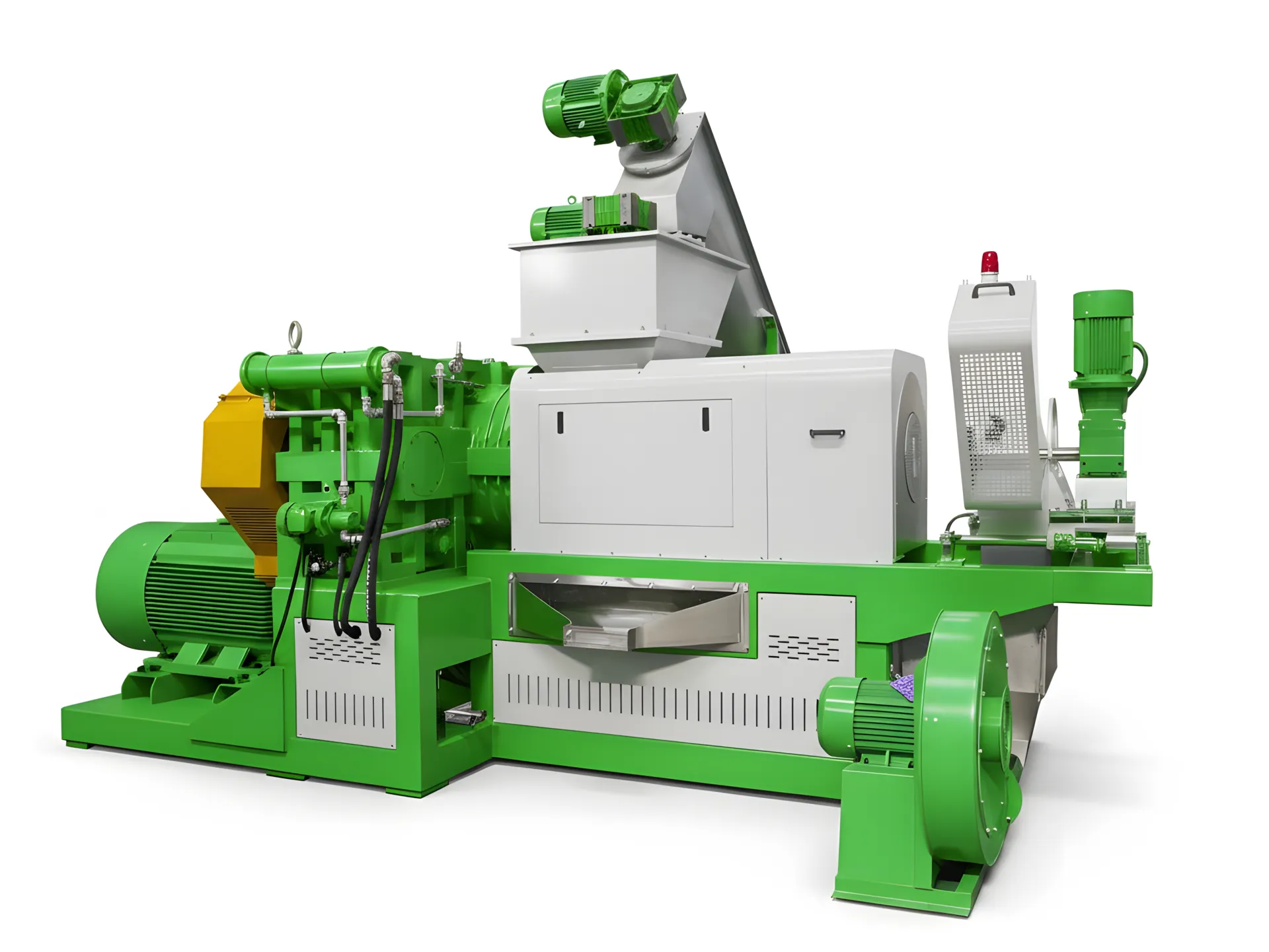

View detailsFilm Squeezer System High-compression dewatering screw

Twin-feed augers meter slurry into a tapered screw that wrings water through perforated barrels while induction heaters flash off the remaining surface moisture, giving flexible film a dense, easily conveyed plug for downstream pelletizing.

View detailsCentrifugal Flake Dryer Blade-tuned rotor for flakes & film

A hardened stainless rotor, self-cleaning screens, and vibration isolation spin water off PET, HDPE, and PP flakes at up to 1,000 rpm, lowering residual moisture below 1% before the stream hits surge bins or air conveyors.

View detailsVertical Mixing Dryer Heated helix keeps batches uniform

Spiral paddles lift pellets through a jacketed column so every particle sees the same residence time, enabling simultaneous mixing, moisture removal, and additive coating before material flows straight into extruders or storage silos.

View details