Bac de séparation par flottaison pour le recyclage des bouteilles en PET

Rumtoo’s sink-float separation tank uses water density to wash and separate sinking PET flakes from floating PP/PE caps and labels—boosting purity for downstream hot-wash, friction, drying, and pelletizing.

- Density-based PET vs PP/PE separation

- Washing and soaking in one continuous tank

- Screw discharge + skimming drums for stable output

Turn Mixed Bottle Flakes into High-Purity PET

After crushing, PET bottle flakes are usually mixed with floating contaminants like PP/PE caps, rings, and label fragments. In a sink-float tank, PET (density ~1.38 g/cm³) sinks while PP/PE (0.90–0.96 g/cm³) floats. This simple physics step is one of the most effective ways to raise PET purity before drying and extrusion.

- Separates PET sinks from caps/labels in a continuous wash stage.

- Long tank length provides soaking time to loosen dirt and glue residues.

- Engineered for stable feeding to friction washers, dewatering, and dryers.

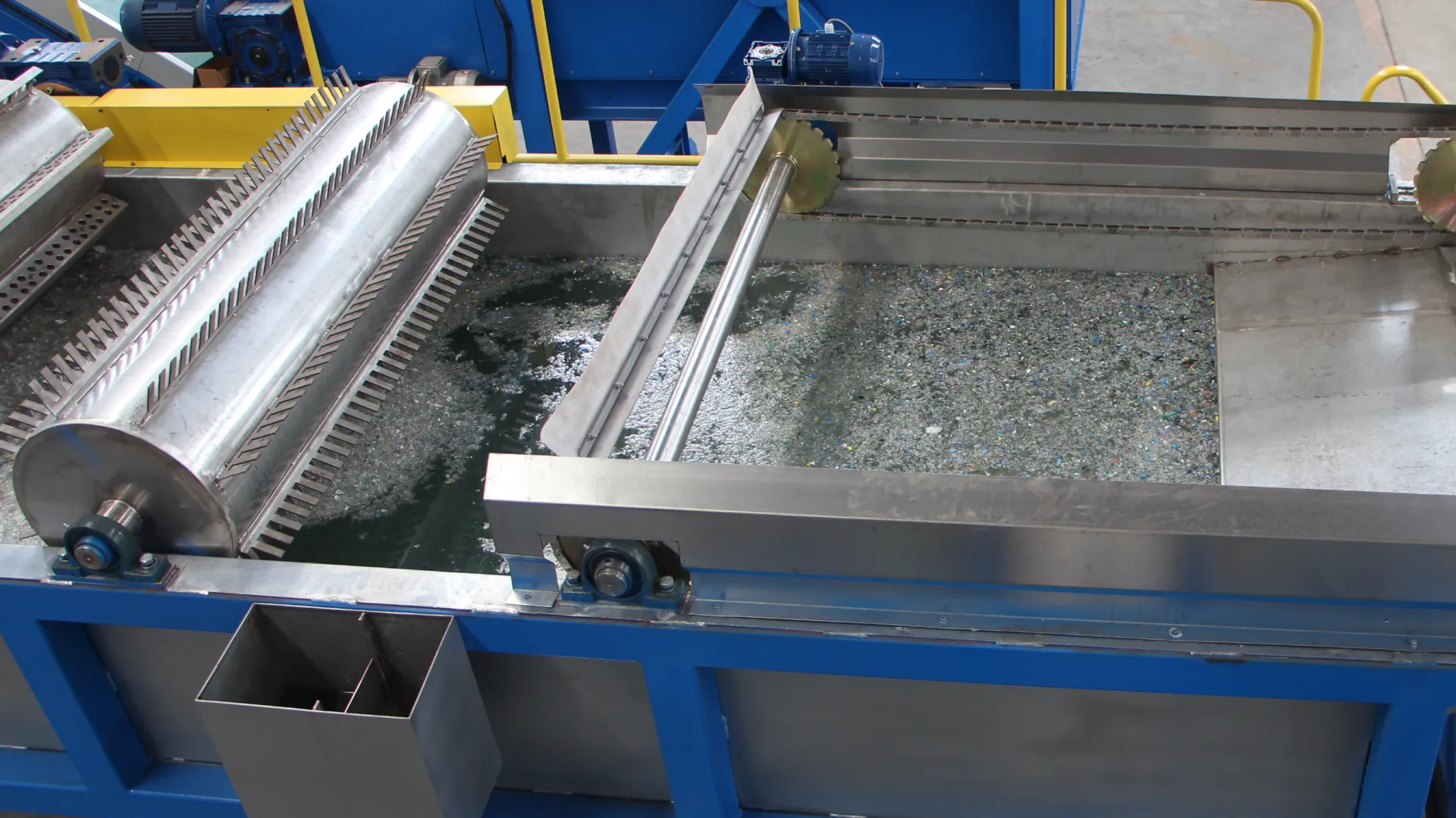

PET sinks are discharged by a bottom screw conveyor, while rotating surface drums skim floating caps and labels.

Principaux avantages

Improve PET flake purity, stabilize downstream throughput, and reduce waste losses from mis-sorted material streams.

Higher PET Purity

Remove floating PP/PE caps and labels reliably so your PET stream is cleaner for hot-wash, drying, and extrusion.

Durable Wet-End Build

304 stainless steel contact surfaces resist corrosion and support continuous operation in demanding washing environments.

More Washing Time

Extended tank geometry improves soaking and rinsing, helping remove dirt and fine contaminants before dewatering.

How the Sink-Float Tank Works

A straightforward, continuous process separates PET flakes from floating bottle caps and labels.

Mixed bottle flakes enter the water bath. Agitation and residence time help loosen dirt and label residues.

PET sinks while PP/PE caps and label fragments float. The tank keeps each fraction moving toward its discharge point.

A bottom screw conveyor removes PET sinks; surface skimming drums or paddles push floats to a separate outlet.

Applications typiques

Used wherever mixed rigid flakes must be separated by density and washed for higher downstream quality.

PET Bottle Recycling Lines

Separate PET sinks from caps and labels before friction washing, dewatering, and thermal drying.

Post-Consumer Rigid Sorting

Split mixed rigid streams into float and sink fractions to improve purity and reduce manual sorting load.

Pre-Pelletizing Purification

Deliver cleaner flakes into pelletizing and extrusion systems to reduce black specks, gels, and contamination defects.

Principaux paramètres techniques (typiques)

Representative configurations for PET bottle washing lines. Dimensions and motors can be customized to your throughput and plant layout.

| Spécification | Valeur (référence) |

|---|---|

| Interior width | 1,500–2,000 mm |

| Total length | 4–6 m |

| Interior material | Type 304 stainless steel |

| Exterior frame | Acier au carbone |

| Screw conveyor motors | 5.5 kW + 3.7 kW |

| Rotating drum motors | 0.37 kW + 2.2 kW |

All parameters above are for reference only. Rumtoo can customize tank length, drives, water circulation, and discharge layout for your materials and contamination levels.

Conseils d'utilisation et d'entretien

Keep separation performance stable with simple daily checks and routine cleaning.

Before Start-up

- Confirm water level and overflow routing are set.

- Inspect the screw conveyor and skimming drums for obstructions.

- Check bearings, reducers, and guards before running.

During Operation

- Maintain a steady feed rate to avoid turbulence and carryover.

- Monitor float discharge; adjust skimming speed as needed.

- Remove accumulated sinks and sediment on schedule.

Soins de routine

- Flush the tank periodically to control fines buildup.

- Inspect screw flights and wear points; tighten fasteners.

- Verify motor current and vibration for early fault detection.

Questions fréquemment posées

What separation purity can I expect for PET flakes?

When upstream shredding and washing are stable, sink-float separation is a highly effective step for removing floating PP/PE caps and labels. Rumtoo can recommend tank length, agitation, and discharge settings based on your contamination level.

Does the tank also remove PVC?

PVC is denser than water, so it sinks together with PET in a standard sink-float tank. For PET/PVC separation, Rumtoo typically recommends upstream sorting (e.g., optical sorting) or specialized separation methods.

How often do we need to change the water?

Most lines run the tank with recirculated water and continuous make-up water. Change frequency depends on dirt load, labels, and fines. Rumtoo can design water management and filtration to reduce consumption.

Can the tank be integrated into an existing PET line?

Yes. Rumtoo can provide layout guidance and connection interfaces for conveyors, friction washers, dewatering equipment, and piping in retrofit projects.

Configure Your Sink-Float Separation Tank

Share your PET throughput, flake size, and contamination mix. Rumtoo engineers will recommend tank dimensions, discharge layout, and water management options.

- Layout support for new builds and retrofits

- Designed to pair with friction washing, dewatering, and drying modules

- Worldwide delivery with commissioning guidance