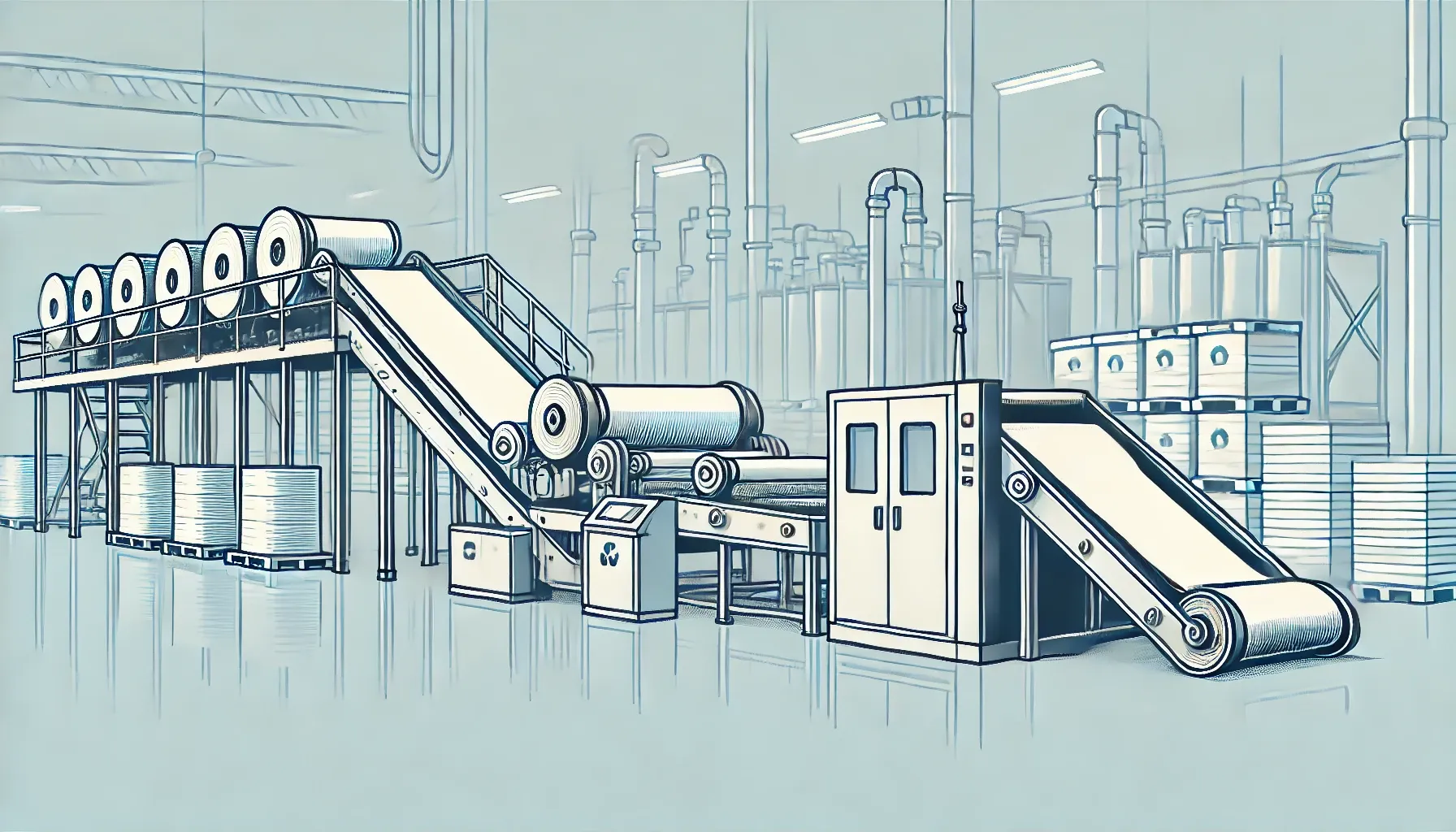

Recycling plastic film is a critical step toward a sustainable future. If you’re considering investing in a plastic film recycling machine, it’s essential to understand the factors that influence its cost. Here, we’ll explore the various elements that contribute to the pricing of these machines, from technology and capacity to the reputation of the manufacturer.

Factors Influencing the Cost of Plastic Film Recycling Machines

1. Technology and Features

The technology incorporated into a plastic film recycling machine plays a significant role in determining its price. Machines with advanced features, such as automated sorting, shredding, washing, and pelletizing, typically cost more. These advanced systems enhance efficiency, reduce labor costs, and provide higher quality recycled material, justifying the higher investment.

2. Capacity and Throughput

The capacity of the machine, measured in kilograms per hour (kg/h), directly affects the cost. Higher capacity machines can process more plastic film in a shorter time, making them suitable for large-scale operations. However, these machines require a larger initial investment. Smaller capacity machines, while less expensive, may not meet the demands of high-volume recycling centers.

3. Manufacturer Reputation and Quality

The reputation and reliability of the manufacturer are crucial factors. Renowned manufacturers with a track record of producing durable, efficient, and high-quality machines tend to charge a premium. Investing in a machine from a reputable manufacturer can ensure better performance, longevity, and after-sales support, which can save costs in the long run.

4. Customization and Add-ons

Many manufacturers offer customization options and add-ons, such as enhanced control systems, energy-efficient components, and additional processing stages. These customizations can significantly increase the cost but also enhance the machine’s functionality and efficiency, tailored to specific recycling needs.

5. Geographical Location and Import Costs

The geographical location of the buyer can influence the price due to shipping and import costs. Machines manufactured locally might be less expensive compared to imported ones, considering the additional costs of international shipping, duties, and taxes.

6. Energy Consumption and Efficiency

Energy-efficient machines, while often more expensive upfront, can lead to substantial savings in operational costs over time. Machines designed to minimize energy consumption without compromising performance are becoming increasingly popular despite their higher initial cost.

7. Warranty and After-Sales Service

A comprehensive warranty and reliable after-sales service can add to the initial cost but provide peace of mind and protect against future expenses. Manufacturers offering extended warranties and robust customer support often charge more, reflecting the added value of these services.

Conclusion

The cost of a plastic film recycling machine varies widely based on technology, capacity, manufacturer reputation, customization options, and other factors. Investing in a high-quality machine may require a significant initial outlay but can lead to long-term savings and higher efficiency in your recycling operations.

For more detailed information on specific models and pricing, you can check out the plastic film recycling machine from reputable manufacturers.

By understanding these factors, you can make an informed decision and choose a plastic film recycling machine that best suits your needs and budget.