Choosing the right 3d filament extruder is a significant decision for any professional enterprise. It is not merely a purchase. It is an investment in your operational independence, material innovation, and financial bottom line. For businesses tired of supply chain delays, high filament costs, and limitations on material choices, an in house extruder offers a clear path forward. This guide provides a direct, practical framework for purchasing managers and technical leads to select a machine that delivers both performance and long term value.

We will move beyond simple feature lists. Instead, we will focus on the core engineering principles that define an extruder’s efficiency and durability. You will learn what specifications truly matter and how they translate into tangible benefits for your work.

Understanding the Core Function of a 3D Filament Extruder

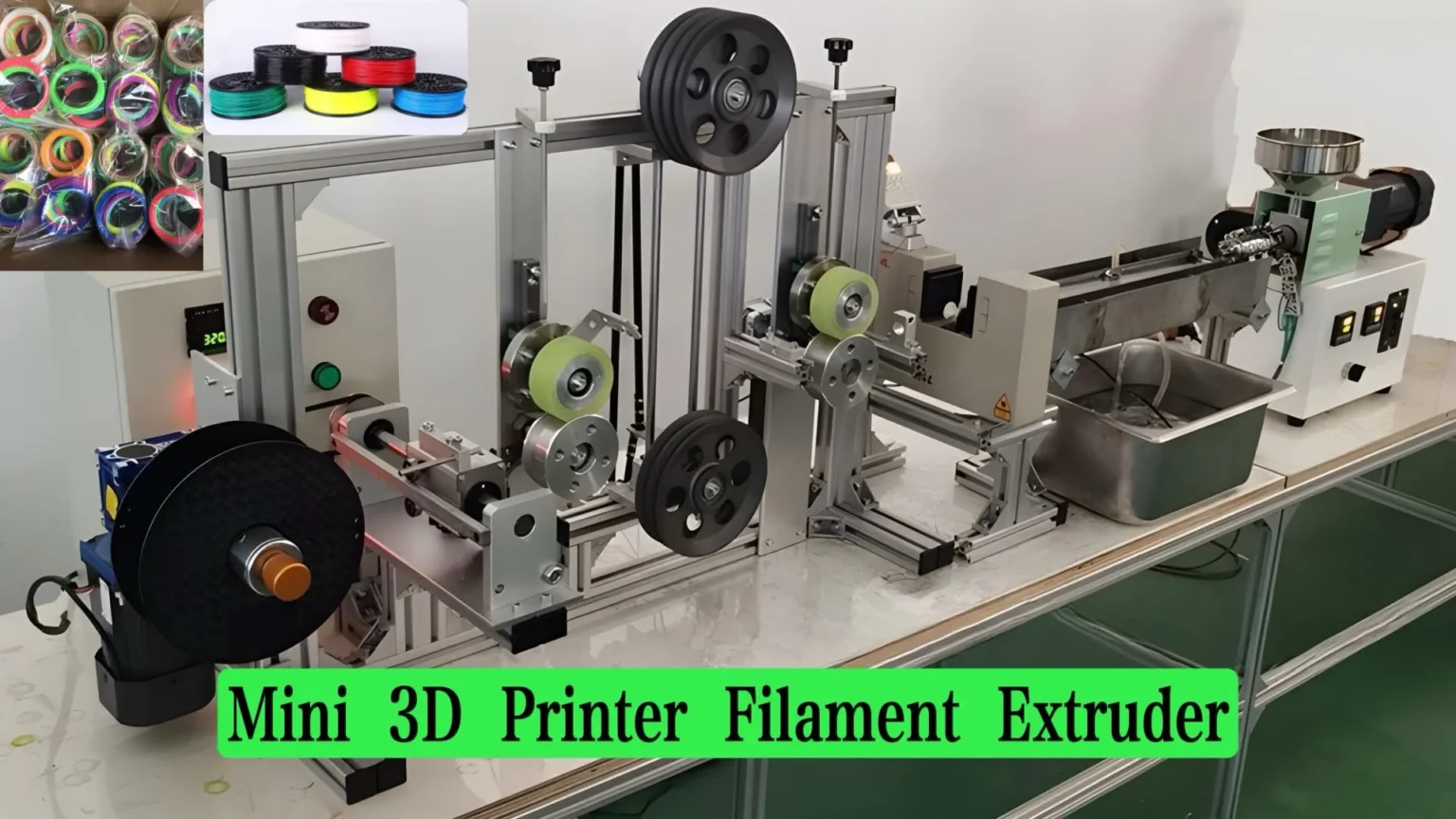

At its heart, a 3D filament extruder performs a straightforward task. It takes raw plastic pellets, melts them under precise thermal conditions, and pushes the molten material through a die to form a continuous strand of filament with a specific diameter. The machine then cools this filament and winds it onto a spool, ready for use in a 3D printer.

However, the difference between a consumer grade toy and a professional tool lies in the consistency and control of this process. For a business, an extruder is a production asset. It must create high quality filament hour after hour, day after day. This level of performance enables three primary business advantages:

- Cost Reduction: Buying raw plastic pellets is significantly cheaper than purchasing spooled filament. The savings can be as high as 70-80%, leading to a rapid return on investment.

- Material Innovation: You gain the freedom to create custom polymer blends, experiment with additives like carbon fiber or wood, and develop proprietary materials for specific applications.

- Supply Chain Control: Producing filament in house eliminates dependence on external suppliers, reduces lead times, and ensures you always have the material you need.

Key Factors in Selecting a High Performance Extruder

When you evaluate a 3D filament extruder, focus on the components that directly impact quality and output. A machine is only as strong as its weakest link. Here are the critical areas to examine.

The Screw: The Heart of the Machine

The screw is arguably the most important component. It conveys, melts, and pressurizes the plastic. Its design dictates how well the machine handles different materials. Look for a screw made from hardened steel, such as nitrided or chrome plated tool steel, for wear resistance.

Pay close attention to the L/D ratio (Length-to-Diameter ratio). A higher L/D ratio, typically 20:1 or greater, provides a longer residence time for the plastic inside the barrel. This allows for more gradual and uniform melting, which is essential for heat sensitive polymers and achieving a homogenous melt.

Motor and Drive System: The Power Behind Precision

The drive system turns the screw. Its ability to maintain a constant speed under load is critical for producing filament with a consistent diameter. A variable speed DC motor with a high quality gearbox is the industry standard. It provides the necessary torque to process high viscosity materials without stalling. Ask the manufacturer about the motor’s power rating (in Watts or Horsepower) and the type of speed controller it uses. A reliable drive system ensures stable output, which is a cornerstone of efficiency.

Temperature Control: The Key to Filament Quality

Precise temperature control is non negotiable. Most professional extruders use multiple heating zones along the barrel, each managed by a PID (Proportional-Integral-Derivative) controller. This setup allows you to create a specific temperature profile, starting cooler at the feed throat and getting hotter towards the die. This precision prevents material degradation and ensures the plastic reaches the ideal viscosity for extrusion. Machines with at least two or three independent heating zones offer far greater process control than those with a single zone.

Material Compatibility: From Standard to Exotic

Your chosen extruder must be able to process the materials you need today and in the future. A machine capable of reaching temperatures of at least 300°C can handle common polymers like PLA, ABS, and PETG. For high performance materials like PEEK or Ultem, you will need a machine capable of 400°C or higher. The quality of the screw, motor torque, and temperature control system all contribute to a machine’s material versatility. You can find extensive data on polymer melt temperatures from reliable sources like the British Plastics Federation.

Extrusion Speed and Output Rate (kg/hr)

Efficiency is measured by how much quality filament a machine can produce in a given time. This is typically expressed in kilograms per hour (kg/hr) or pounds per hour (lbs/hr). While a higher output rate seems better, it must not come at the expense of quality. The ideal machine balances speed with diameter consistency. For a lab or small production environment, an output of 0.5 to 2 kg/hr is often a practical and effective range.

Durability and Build Quality: An Investment for the Long Term

A professional extruder should be built to last. Examine the machine’s construction. A sturdy, heavy gauge steel frame minimizes vibration and ensures alignment of the drive and barrel. Check the quality of components like bearings, heaters, and electrical wiring. Reputable manufacturers are transparent about their component suppliers. This focus on build quality ensures the machine remains a productive asset for your company for many years.

Diameter Control and Spooling: Ensuring Usable Filament

Producing a filament strand is only half the battle. That strand must have a highly consistent diameter (e.g., 1.75mm or 2.85mm ±0.05mm) to be useful in a 3D printer. High end systems use a dual axis laser diameter sensor to monitor the filament in real time. This sensor feeds data back to the machine’s controller, which automatically adjusts the puller speed to maintain the target diameter. This closed loop control is the defining feature of a truly professional system. An integrated, speed controlled spooler is also essential for neatly winding the finished filament without stretching or tangling.

Calculating the Return on Investment (ROI) for Your Business

A professional 3D filament extruder is a capital expense, and its purchase must be financially justified. Here is a simple way to frame the ROI calculation:

- Calculate Annual Filament Costs: Determine how many kilograms of filament your business uses per year and its average cost per kilogram. (e.g., 200 kg/year * $25/kg = $5,000)

- Calculate Pellet Costs: Research the cost of the same raw material in pellet form. (e.g., 200 kg/year * $5/kg = $1,000)

- Determine Annual Savings: Subtract the pellet cost from the filament cost. (e.g., $5,000 – $1,000 = $4,000 annual savings)

- Calculate Payback Period: Divide the total cost of the extruder system by the annual savings. (e.g., $8,000 extruder cost / $4,000 annual savings = 2 years)

This simple calculation does not even include the added value of creating custom materials or avoiding production downtime, which makes the investment even more compelling.

A Practical Checklist for Your Purchase Decision

Use this checklist to compare different 3D filament extruder models:

- Screw: Is it made of hardened steel? What is the L/D ratio?

- Motor: Is it a variable speed DC motor with sufficient torque?

- Heating: How many independent heating zones are there? Does it use PID control?

- Temperature Range: Does it meet the requirements for your target materials?

- Control System: Does it offer closed loop diameter control with a laser sensor?

- Build Quality: Is the frame made of heavy gauge steel? Are the components from reputable brands?

- Manufacturer Support: What kind of warranty, technical support, and documentation is provided?

The Rumtoo Machine Advantage

At Rumtoo Machine, we design equipment with these professional requirements at the forefront. Our machines are engineered for durability and precision, providing a reliable platform for both production and research. For example, our small laboratory single screw extruder incorporates a hardened screw, multiple PID controlled heating zones, and a robust drive system, making it an ideal choice for organizations looking to take control of their filament production. We believe in empowering our clients with tools that deliver measurable value.

Frequently Asked Questions (FAQ)

How much does a professional extruder cost?

Entry level professional systems with basic controls can start around $3,000 to $5,000. More advanced systems with closed loop diameter control, integrated cooling, and automated spooling typically range from $8,000 to $20,000 or more, depending on output and features.

Can I use recycled plastic pellets?

Yes, using recycled materials is one of the key benefits of an in house extruder. However, the recycled plastic must be clean, dry, and of a consistent type. Contaminants or moisture can severely impact filament quality and potentially damage the machine.

What maintenance is required?

Regular maintenance includes cleaning the screw and barrel between material changes (purging), checking for loose electrical connections, and lubricating the gearbox according to the manufacturer’s schedule. A well maintained machine will provide many years of reliable service.

Conclusion: A Strategic Investment in Your Capabilities

Choosing an efficient and durable 3D filament extruder is a strategic decision that enhances your organization’s capabilities. By focusing on the core engineering principles of the screw, drive system, and temperature control, you can select a machine that serves as a reliable production tool. This investment will not only reduce your material costs but also open new doors for innovation. Make an informed choice, and you will equip your team for success.

Disclosure: This article was created with the assistance of artificial intelligence technologies to help organize research and structure content. The final text, including all technical analysis and recommendations, was written, reviewed, and edited by our human expert to ensure accuracy and value.