The growing global emphasis on sustainability and environmental responsibility has pushed industries across the USA and Europe to adopt robust recycling solutions. Macchina Rumtoo, an innovator in recycling machinery, continues to lead by offering high-performance plastic recycling machines tailored to meet the evolving needs of manufacturers, industrial recycling equipment buyers, and industry professionals.

This comprehensive guide explores the wide array of waste materials that Rumtoo Machine’s plastic recycling machines can process effectively, enhancing both sustainability and operational efficiency.

Why Recycling Matters in Industrial Sectors

Industries face growing pressure to reduce environmental impact and optimise resource use. Recycling machines offer a viable solution by significantly reducing waste, lowering raw material costs, and improving sustainability metrics.

Rumtoo Machine recognises the critical importance of recycling and develops innovative equipment designed specifically for industrial-scale plastic recycling, offering significant environmental and economic benefits.

Key Types of Waste Processed by Rumtoo Machine’s Plastic Recycling Equipment

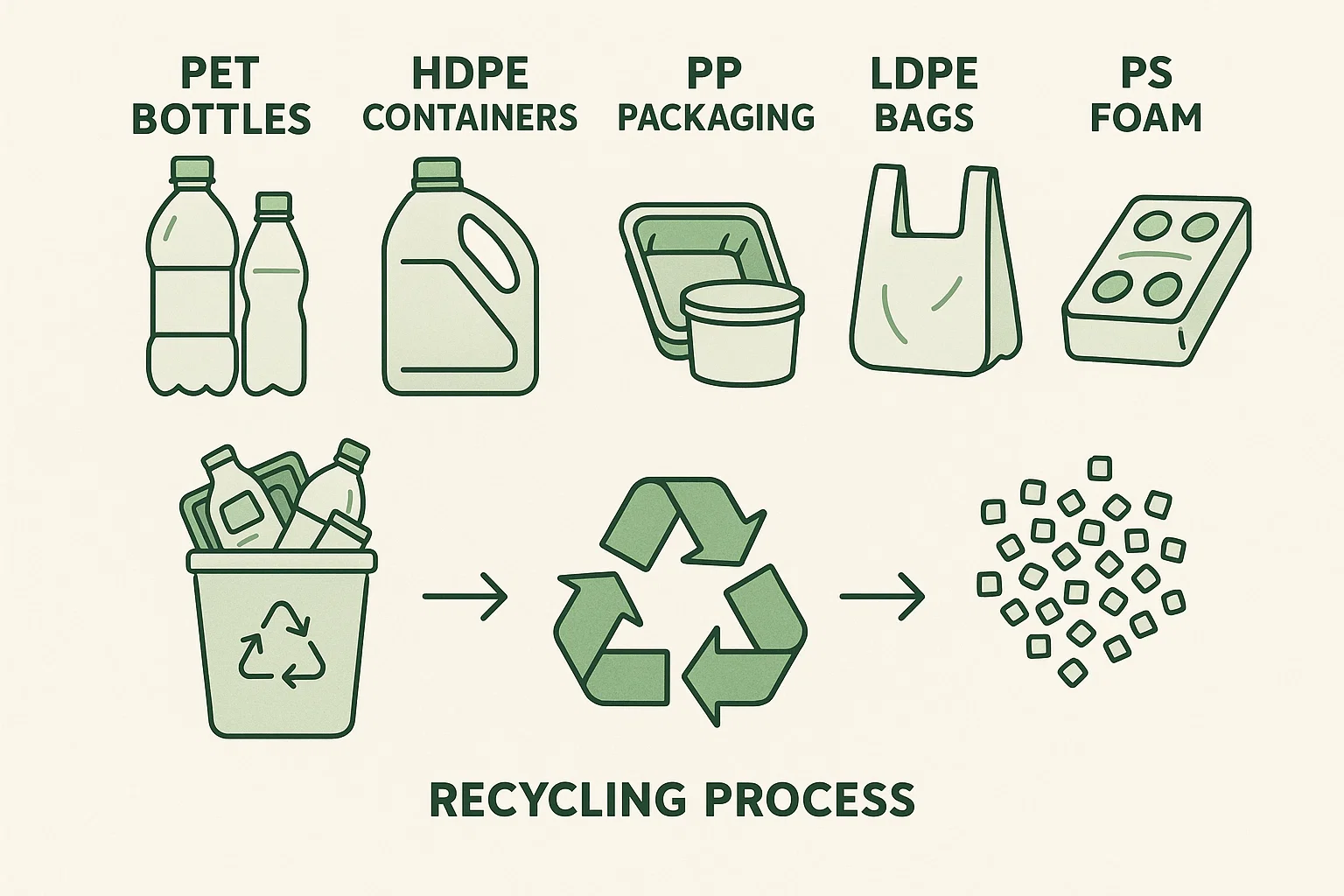

Rumtoo Machine’s advanced macchine per il riciclaggio della plastica can efficiently handle a diverse range of plastic waste, including:

1. Polyethylene Terephthalate (PET)

Widely used for beverage bottles and food containers, PET is highly recyclable. Rumtoo Machine’s equipment can effectively shred, clean, and pelletise PET waste, providing high-quality recycled material suitable for manufacturing new products.

2. High-Density Polyethylene (HDPE)

Commonly found in bottles, milk jugs, and industrial containers, HDPE recycling is streamlined by Rumtoo Machine’s advanced sorting, washing, and granulating technologies, delivering recycled materials ideal for remanufacturing.

3. Polypropylene (PP)

Used in packaging, automotive parts, and household items, PP is effectively recycled through Rumtoo Machine’s dedicated recycling machinery. These systems efficiently process PP waste, maintaining material integrity and quality.

4. Low-Density Polyethylene (LDPE)

Found in plastic bags, films, and wrapping materials, LDPE recycling is facilitated by Rumtoo Machine’s specialised film recycling equipment, producing reusable granules for various industrial applications.

5. Polystyrene (PS)

Rumtoo Machine provides tailored solutions for recycling polystyrene, commonly used in packaging, disposable containers, and insulation. Their machines compress and pelletise PS efficiently, reducing environmental pollution significantly.

Technical Workflow: How Rumtoo Machine Plastic Recycling Machines Operate

Rumtoo Machine ensures optimum performance through a streamlined recycling workflow, illustrated below:

- Sorting and Preparation: Plastic waste is meticulously sorted by type and colour.

- Shredding and Granulation: Waste is shredded into small, manageable granules.

- Cleaning and Drying: Granules undergo rigorous washing and drying processes to remove contaminants.

- Melting and Extrusion: Cleaned granules are melted down and extruded into pellets.

- Quality Testing: Rigorous quality assessments ensure recycled materials meet industry standards.

Comparative Analysis: Performance and Efficiency

Rumtoo Machine’s plastic recycling equipment provides measurable advantages:

- Efficienza energetica: Machines utilise advanced technologies to significantly reduce energy consumption.

- Operational Speed: Higher processing speeds increase throughput and reduce production downtime.

- Material Quality: Consistently high-quality recycled plastics are achievable through precise process control mechanisms.

Visual Enhancement: Machinery Workflow Diagram

[Include a clear, detailed diagram illustrating the workflow steps mentioned above, showcasing each phase clearly and visually appealing to technical readers.]

Industry Applications of Recycled Plastics

Recycled plastics produced by Rumtoo Machine equipment are widely used across various industries:

- Packaging Industry: Sustainable packaging solutions.

- Automotive Sector: Components manufactured from recycled materials.

- Construction Industry: Insulation and construction materials derived from recycled plastics.

FAQ Section

Q1: What are the main benefits of investing in a plastic recycling machine?

Investing in a plastic recycling machine offers reduced waste disposal costs, environmental compliance, enhanced sustainability metrics, and significant savings on raw material expenses.

Q2: How do I choose the right recycling equipment for my business?

Consider your processing capacity, types of plastic waste, desired quality of output, and operational budget. Rumtoo Machine specialists can assist in selecting the most suitable equipment tailored to your needs.

Q3: Are Rumtoo Machine recycling machines easy to operate and maintain?

Yes, Rumtoo Machine prioritises user-friendly interfaces, ease of maintenance, comprehensive training, and dedicated customer support to ensure smooth operations.

Q4: Can recycled plastic be used to manufacture new high-quality products?

Absolutely. Recycled plastics processed by Rumtoo Machine meet strict quality standards, making them suitable for various high-quality industrial and consumer products.

Conclusion and Call-to-Action

Rumtoo Machine remains committed to providing advanced, reliable, and efficient recycling solutions. Our plastic recycling machines empower businesses across the USA and Europe to achieve sustainability goals and operational efficiency.

Explore how Rumtoo Machine can enhance your recycling processes. Contact our experts today or visit our website to request a customised quote tailored to your recycling requirements.