In an era defined by the push for sustainability and the circular economy, the plastic recycling industry presents not just an environmental imperative but a significant commercial opportunity. As governments in Europe and the USA tighten regulations on single-use plastics and landfill waste, the demand for high-quality recycled polymers is soaring. However, launching a successful plastic recycling plant is a complex venture that requires meticulous planning, substantial investment, and deep technical knowledge.

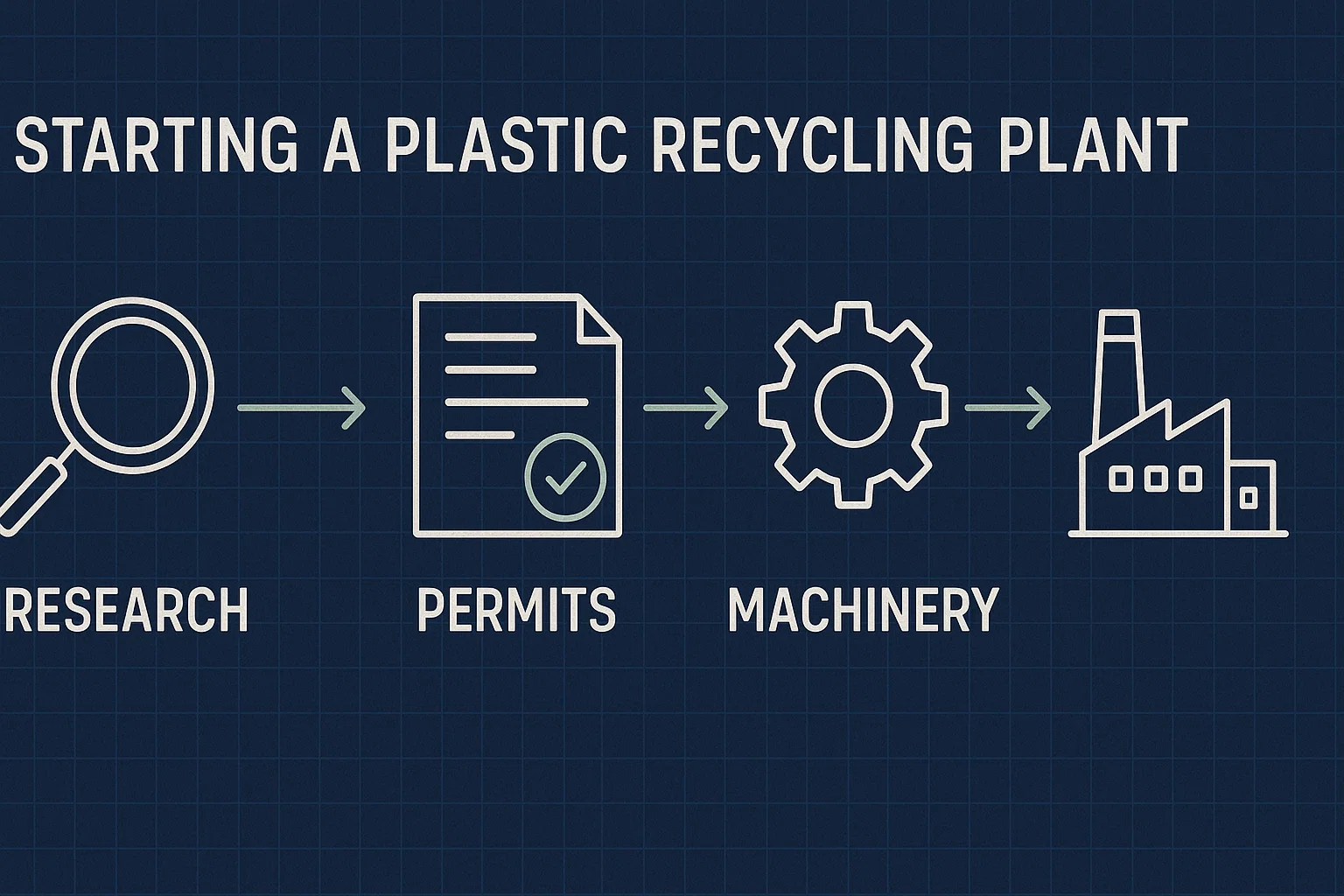

This comprehensive guide is designed for entrepreneurs, manufacturers, and industrial professionals looking to enter this rewarding sector. We will break down the essential steps, from initial market research to final profitability analysis, providing a clear roadmap for 2025 and beyond. As a leader in recycling technology, Rumtoo Machine is committed to sharing our expertise to help you build a profitable and sustainable business from the ground up.

Step 1: Laying the Foundation – Market Research and a Robust Business Plan

Before a single piece of equipment is purchased, a thorough and realistic business plan must be developed. This is your blueprint for success and will be crucial for securing financing and guiding your operational strategy.

Identifying Your Niche and Feedstock

Not all plastics are created equal. Your first critical decision is to determine which type(s) of plastic you will process. Common choices include:

- PET (Polyethylene Terephthalate): Widely used for beverage bottles. A mature and stable market for recycled PET (rPET).

- HDPE (High-Density Polyethylene): Found in milk jugs, detergent bottles, and pipes. Valued for its durability.

- LDPE/LLDPE (Low-Density Polyethylene): Primarily used for plastic films, carrier bags, and packaging. Requires specialised washing processes.

- PP (Polypropylene): Used in car parts, containers, and woven bags.

- Hard/Rigid Plastics vs. Soft Films: The machinery and processes differ significantly. A plant designed for rigid HDPE bottles will not be suitable for processing contaminated PE agricultural film without the right configuration.

Your market research must analyse the availability of these plastics in your target region. Are there established municipal collection schemes? Can you partner with large industrial waste producers or retailers to secure a consistent, high-volume supply? The quality and contamination level of your feedstock will directly impact your processing costs and the value of your final product.

Analysing the End-Market

Who will buy your recycled plastic? Identify potential customers for your recycled flakes or pellets. These could be:

- Packaging manufacturers are creating bottles or containers with recycled content.

- Textile companies are spinning polyester fibre from rPET.

- Automotive parts suppliers.

- Construction companies are using recycled plastics in building materials.

Understanding their quality specifications and pricing expectations is vital. This will dictate the level of technology and quality control required in your plant.

Step 2: Navigating the Legal Labyrinth – Permits and Compliance

Operating a recycling plant is a heavily regulated activity. Gaining a full understanding of the legal requirements in your chosen location (be it a US state or a European country) is non-negotiable. Key areas of compliance include:

- Environmental Permits: You will almost certainly need permits relating to air quality (emissions), water discharge (from washing processes), and waste management. Regulatory bodies like the Environmental Protection Agency (EPA) in the USA and corresponding national agencies in Europe have stringent standards.

- Operating Licences: A specific business licence to operate an industrial or waste processing facility will be required from local or regional authorities.

- Zoning and Land Use: The site you choose must be zoned for heavy industrial use.

- Health and Safety Regulations: Compliance with workplace safety standards (e.g., OSHA in the US, HSE in the UK) is mandatory to protect your employees.

- CE Marking (Europe): All machinery, including your recycling lines, must be CE marked to certify it meets EU safety, health, and environmental protection requirements. When you partner with a trusted supplier like Rumtoo Machine, you can be confident that the equipment meets these international standards.

Engaging with an environmental consultant early in the process can save significant time and prevent costly mistakes.

Step 3: Location, Location, Location – Selecting the Ideal Site

The physical location of your plant is a strategic decision that impacts logistics, costs, and operational efficiency. Consider the following factors:

- Proximity to Feedstock: A site closer to your sources of waste plastic will reduce transportation costs and your carbon footprint.

- Accessibility: The facility must be easily accessible for large lorries delivering raw materials and dispatching finished products.

- Utilities: Plastic recycling is resource-intensive. Ensure the site has access to high-capacity electricity (for shredders, granulators, and extruders), a reliable water supply for washing lines, and adequate drainage.

- Space: You will need sufficient space for feedstock reception and storage, the processing line itself, warehousing for finished products, and administrative offices. Plan for future expansion from day one.

Step 4: The Heart of the Operation – Your Essential Equipment List

The quality, efficiency, and reliability of your machinery will determine your plant’s success. A typical plastic recycling process involves several key stages, and a complete, integrated solution is often the most effective approach. This is where a partner like Rumtoo Machine becomes invaluable, offering end-to-end systems tailored to your specific needs.

A complete recycling line transforms contaminated waste into a high-value commodity. Let’s explore the critical components:

- Size Reduction (Shredding and Crushing): The first step is to break down bulky plastic items into smaller, manageable pieces.

- Plastic Crushers: These powerful machines use high-speed rotating blades to cut plastic into uniform flakes or regrind. The choice of crusher depends on the plastic’s rigidity and thickness. For robust and reliable size reduction, exploring options like our versatile Plasticbreker range is a crucial first step.

- Washing, Separation, and Cleaning: This is arguably the most critical stage for producing a high-quality end-product. Contaminants like dirt, sand, paper labels, and food residue must be thoroughly removed.

- Waslijnen: A modern washing line is a multi-stage system. It can include friction washers, floating/sinking separation tanks (to separate different plastic types like PET and PE/PP), hot washers to remove glue and oil, and high-speed dewatering machines. For processing materials like post-consumer film or heavily soiled rigid plastics, a high-performance system is essential. Our Soft/Hard Plastic Washing Line is engineered to deliver exceptional cleaning efficiency, ensuring your material is pure and ready for the next stage.

- Drogen: After washing, the plastic flakes must be completely dried. Any residual moisture can cause defects during the final melting and extrusion phase. Thermal drying systems are typically used to achieve moisture levels below 1%.

- Pelletising (or Granulation): This is the final value-adding step. The clean, dry flakes are fed into an extruder, where they are melted, filtered to remove any final impurities, and then forced through a die to form spaghetti-like strands. These strands are instantly cooled in a water bath and cut into small, uniform pellets.

- Pelletising Lines: These pellets are the final product, ready to be sold to manufacturers. They are easier to handle, transport, and feed into production machinery than raw flakes. A state-of-the-art Plastic Pelletising Line ensures a consistent melt, excellent filtration, and uniform pellet size, commanding the highest market price.

By investing in a fully integrated system from a single, expert supplier, you ensure that each component works seamlessly with the next, optimising throughput and minimising downtime. At Rumtoo Machine, we specialise in designing these complete turnkey solutions.

Step 5: The Bottom Line – Cost Analysis and Profitability

A clear-eyed financial forecast is essential. Your costs can be broken down into two main categories:

Capital Expenditure (CAPEX):

- Land and Building: Purchase or lease costs.

- Machinery: This will be your largest single investment. The cost varies dramatically based on capacity (kg/hour), the type of plastic, and the level of automation. A complete line can range from hundreds of thousands to several million Euros or Dollars.

- Installation and Commissioning: The cost to install the equipment and get it running.

- Vehicles: Forklifts, lorries, etc.

Operational Expenditure (OPEX):

- Labour: Skilled operators, maintenance technicians, quality control staff, and administrative personnel.

- Utilities: Electricity and water are major ongoing costs. Efficient machinery can significantly reduce this expenditure.

- Raw Material: While some feedstock may be free (or you may even be paid to take it), securing consistent, cleaner sources often involves purchasing baled plastic scrap.

- Onderhoud: Spare parts, lubricants, and regular servicing are essential to keep your line running. Rumtoo Machine provides comprehensive after-sales support and spare parts to maximise uptime.

- Logistics and Transport: Costs for collecting feedstock and delivering the final product.

- Insurance and Licences: Ongoing fees.

Your revenue will come from the sale of recycled pellets or flakes. Prices fluctuate based on the commodity market for virgin plastics, the quality of your product, and the type of polymer. High-purity, food-grade rPET, for example, commands a premium price over mixed-colour, non-food-grade rHDPE.

Profitability hinges on running an efficient, high-uptime operation that consistently produces a high-quality product while carefully managing costs.

Conclusion: Your Partner in the Circular Economy

Starting a plastic recycling plant in 2025 is a journey that demands expertise, capital, and resilience. The challenges are real, but the rewards—both financial and environmental—are immense. The key to success lies in a foundation of detailed research, strict regulatory compliance, and investment in high-quality, reliable machinery.

Navigating the complexities of equipment selection and plant design can be daunting. This is why choosing the right technology partner is as important as choosing the right location. You need a partner who understands the entire process, from waste to pellet, and can provide a solution that is efficient, durable, and tailored to your business goals.

Veelgestelde vragen (FAQ)

1. What is the single biggest challenge when starting a plastic recycling plant?

The most common challenge is securing a consistent and reliable supply of relatively clean feedstock. While there is a lot of plastic waste, sorting it and finding sources that aren’t excessively contaminated is a major logistical and commercial hurdle. Establishing strong relationships with suppliers is key.

2. How much capital is truly needed to start?

This varies enormously. A small-scale plant focusing on a single, clean plastic stream might start in the range of €300,000 – €500,000 for machinery. A large-scale, automated plant capable of processing multiple, highly contaminated streams could easily exceed €2 million. Our team at Rumtoo Machine can help design a line that aligns with your specific budget and business objectives.

3. Is it more profitable to recycle PET bottles or PE films?

Profitability depends entirely on your local market. In some regions, the demand for rPET for bottle-to-bottle recycling is very strong, commanding high prices. In other words, a large supply of commercial or agricultural PE film and a strong local demand for construction materials or plastic bags might make PE recycling more attractive. Thorough market analysis is the only way to answer this for your specific situation.

Ready to Build Your Future in Plastic Recycling?

The journey from concept to a fully operational, profitable recycling plant is complex, but you don’t have to navigate it alone. With decades of experience and a portfolio of cutting-edge technology, the experts at Rumtoo Machine are here to help.

Contact us today for a personalised consultation. Let us help you design the perfect recycling line and provide a detailed quote to turn your vision into reality.