Efficiently crush various plastic waste materials into uniform, high-quality, recyclable granules!

Standard Plastic Granulators

Indispensable for transforming diverse plastic waste into uniform, reusable materials. Critical for sustainability and resource efficiency in the growing field of plastic recycling.

The Core of Plastic Recycling

A Standard Plastic Granulator is a highly efficient machine designed to reduce various types of plastic waste—such as bottles, pipes, containers, and woven bags—into small, uniform particles. These machines are ideal and essential for the modern recycling industry, turning waste into valuable feedstock.

Key Features & Advantages

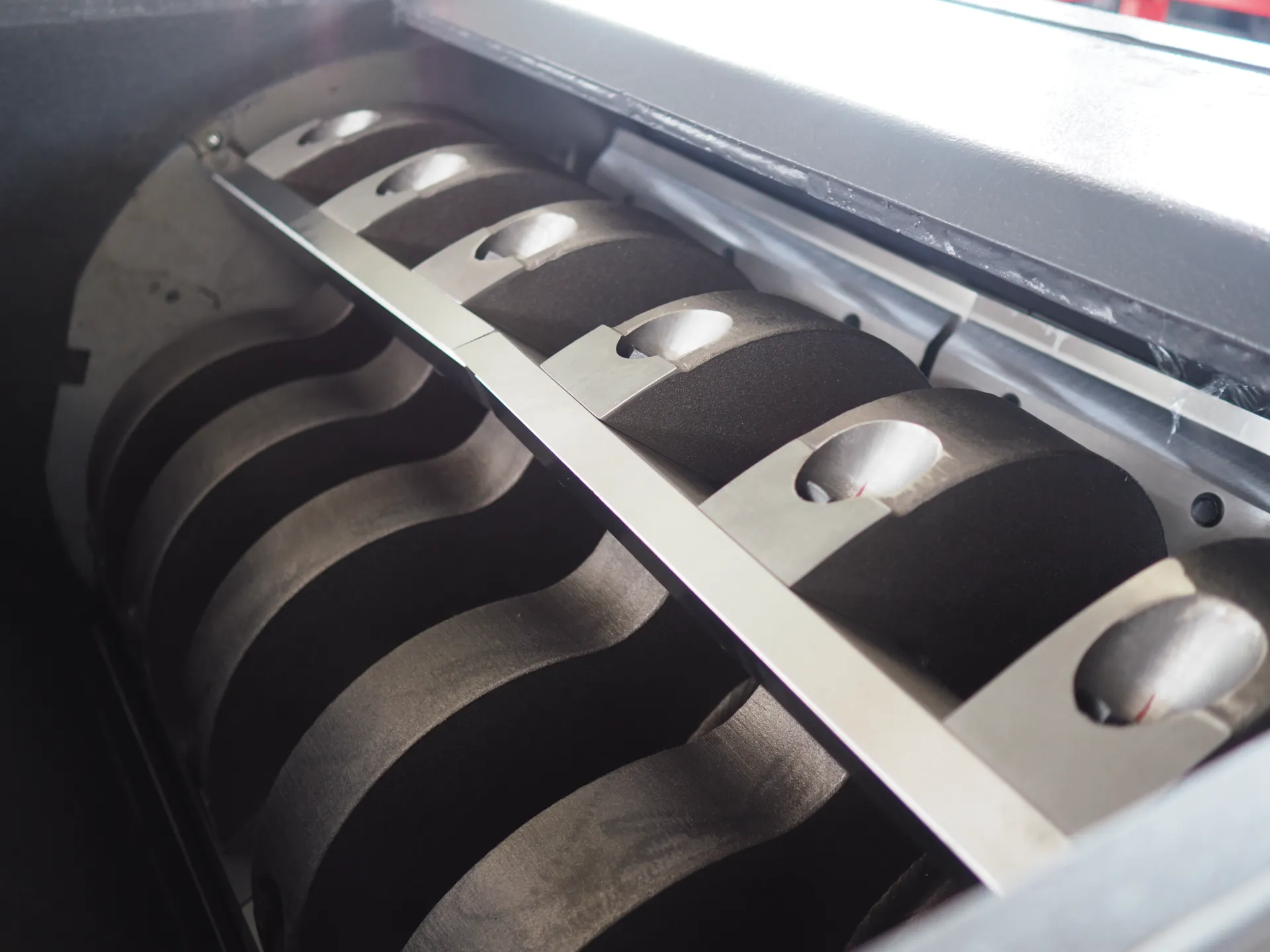

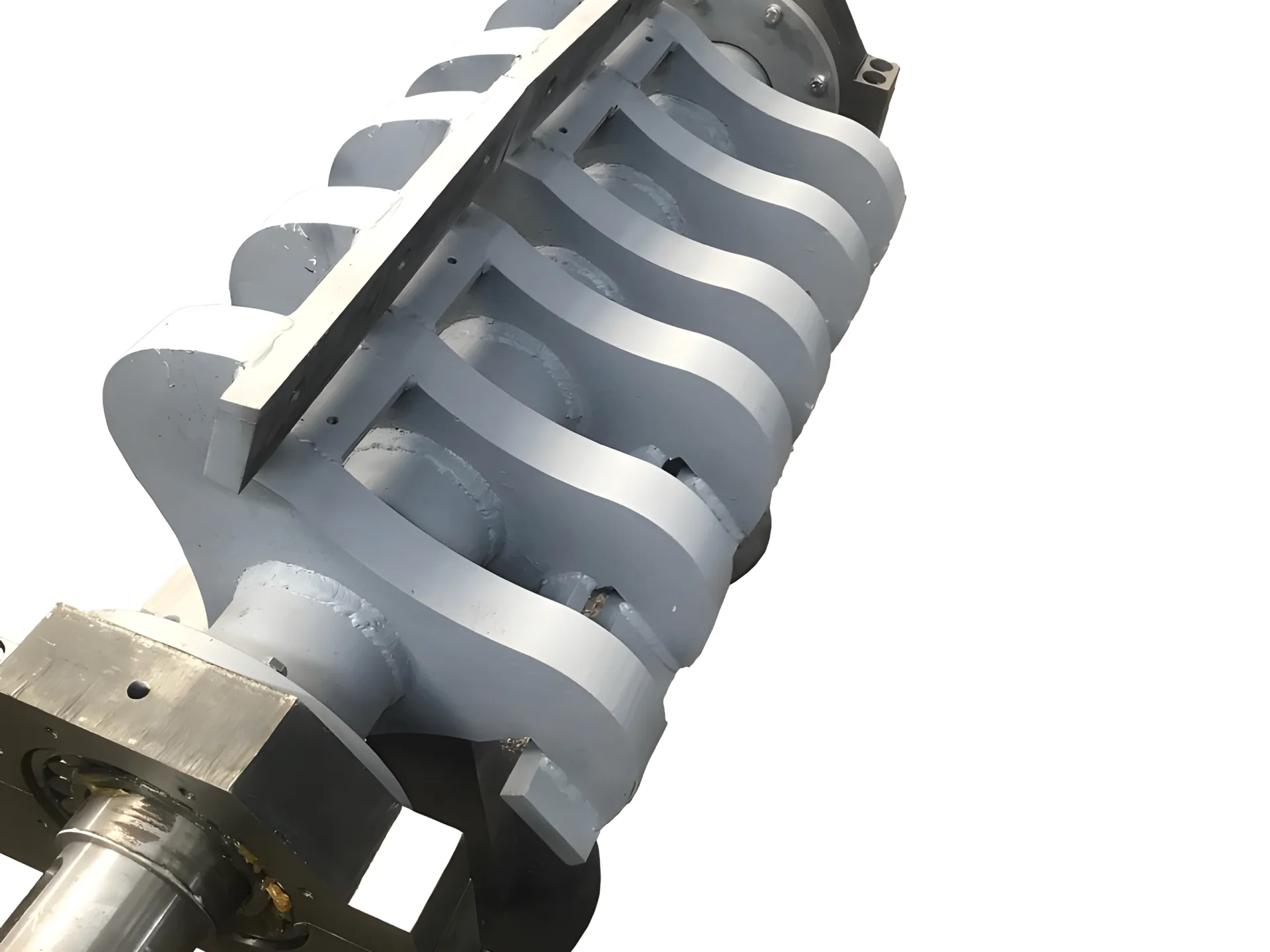

Open Rotor Design

Mounted with heavy-duty knives for efficient cutting and processing of various plastic materials.

Flexible Knife Arrangement

Options for double-scissor or v-shape cuts accommodate different materials and ensure optimal granulation.

Customizable Screen Filters

Screens ranging from 10mm to 100mm allow precise control over final particle size based on specific needs.

Durable D2/SKD11 Steel Knives

Equipped with robust rotor and stationary knives made from highly durable tool steel for extended service life.

Easy Maintenance Access

Hydraulic-assisted or easily accessible cutting chamber simplifies knife adjustments and routine maintenance.

High-Speed, Efficient Operation

Ensures rapid processing and consistent granulation for high throughput and operational efficiency.

How It Works: The Granulation Process

Step 1: Material Feeding & Initial Crushing

Plastic waste is fed into the granulator’s cutting chamber. A high-speed rotor equipped with sharp knives begins to cut and shear the material against stationary knives.

Step 2: Continuous Size Reduction

The material is continuously cut and reduced in size within the chamber until it is small enough to pass through a perforated screen located beneath the rotor.

Step 3: Screen Classification & Discharge

The screen’s hole size determines the final particle size of the granulated material. Once particles meet the size criteria, they are discharged from the machine, ready for the next recycling stage.

Versatile Applications

Post-Consumer Waste

PET bottles, HDPE containers, PP packaging, plastic films.

Industrial & Production Scrap

Pipes, profiles, sheets, runners, purgings, defective parts.

Woven Bags & Bulk Bags

PP/PE woven sacks, FIBCs (Flexible Intermediate Bulk Containers).

Pre-Processing for Pelletizing

Preparing material for subsequent washing, drying, and pelletizing lines.

Technical Parameters

| Model | RTM-600-CR | RTM-800-CR | RTM-1000-CR | RTM-1200-CR |

|---|---|---|---|---|

| Motor Power (kw) | 22/30 | 37/45 | 55/75 | 90/110 |

| Number of Moving Blades (pcs) | 2×3 | 2×3/2×5 | 2×3/2×5 | 2×3/2×5 |

| Number of Fixed Blades (pcs) | 2×2 | 2×2 | 2×2 | 2×2 |

| Crushing Rotary Dimension (mm) | Φ450×600 | Φ580×800 | Φ580×1000 | Φ680×1200 |

| Feeding Mouth Dimension (mm) | 600×700 | 600×1000 | 600×1200 | 600×1200 |

| Screen Aperture (mm) | Φ12-Φ100 | Φ12-Φ100 | Φ12-Φ100 | Φ12-Φ100 |

| Drive Device | Electric | Electric | Electric | Electric |

| Drive Unit Power (kw) | 1.1 | 1.1 | 1.1 | 1.1 |

| Dimensions (mm) | 2160*1620*2900 | 2230*1820*2900 | 2230*2020*2900 | 2230*2020*2900 |

Granulator In Action & Details

Optimize Your Plastic Granulation Process

Our Standard Plastic Granulators offer robust performance and versatility for all your material reduction needs. Contact us for detailed specifications, pricing, and expert consultation.

Frequently Asked Questions

What types of plastic materials can this granulator process?

Our granulators can process a wide range of thermoplastics including PET, HDPE, LDPE, PP, PVC, PS, ABS, PC, and nylon. They handle both rigid plastics (bottles, containers, pipes, profiles) and flexible materials (films, bags, woven sacks). The specific model and blade configuration can be optimized for your target material type.

How do I choose the right granulator model for my needs?

Model selection depends on three key factors: (1) Material type and density, (2) Desired throughput capacity (kg/hr), and (3) Final particle size requirements. For example, RTM-600-CR suits small workshops processing 200-300 kg/hr, while RTM-1200-CR handles industrial-scale operations at 800-1200 kg/hr. Contact us with your material samples and production requirements for a tailored recommendation.

How often do the blades need to be replaced or sharpened?

Blade lifespan depends on material type and operating hours. For soft plastics (PE, PP films), blades typically last 600-1000 operating hours. For harder materials (PET, PC), expect 300-600 hours. Our D2/SKD11 tool steel blades can be resharpened 3-4 times before replacement is necessary. We recommend regular inspection every 200 hours and maintaining spare blade sets for minimal downtime.

Can the granulator be integrated into an automated recycling line?

Absolutely. Our granulators feature standard interfaces for integration with conveyor systems, metal detectors, automatic feeders, and downstream washing or pelletizing equipment. Optional PLC control systems enable full automation, remote monitoring, and synchronization with other production line equipment.

What is the typical return on investment (ROI) period?

ROI varies based on operation scale and material costs, but most customers report payback periods of 12-24 months. By converting waste plastic into valuable regrind for resale or reuse, reducing disposal costs, and improving material handling efficiency, the granulator quickly becomes a profit-generating asset rather than an expense.

What warranty and after-sales support do you offer?

We provide a comprehensive 12-month limited warranty covering manufacturing defects and component failures under normal operating conditions. After-sales support includes: lifetime technical assistance via phone/email, spare parts supply with 48-hour dispatch, remote troubleshooting, optional extended warranty packages, and on-site service visits when required. Training materials and operation videos are included with every purchase.