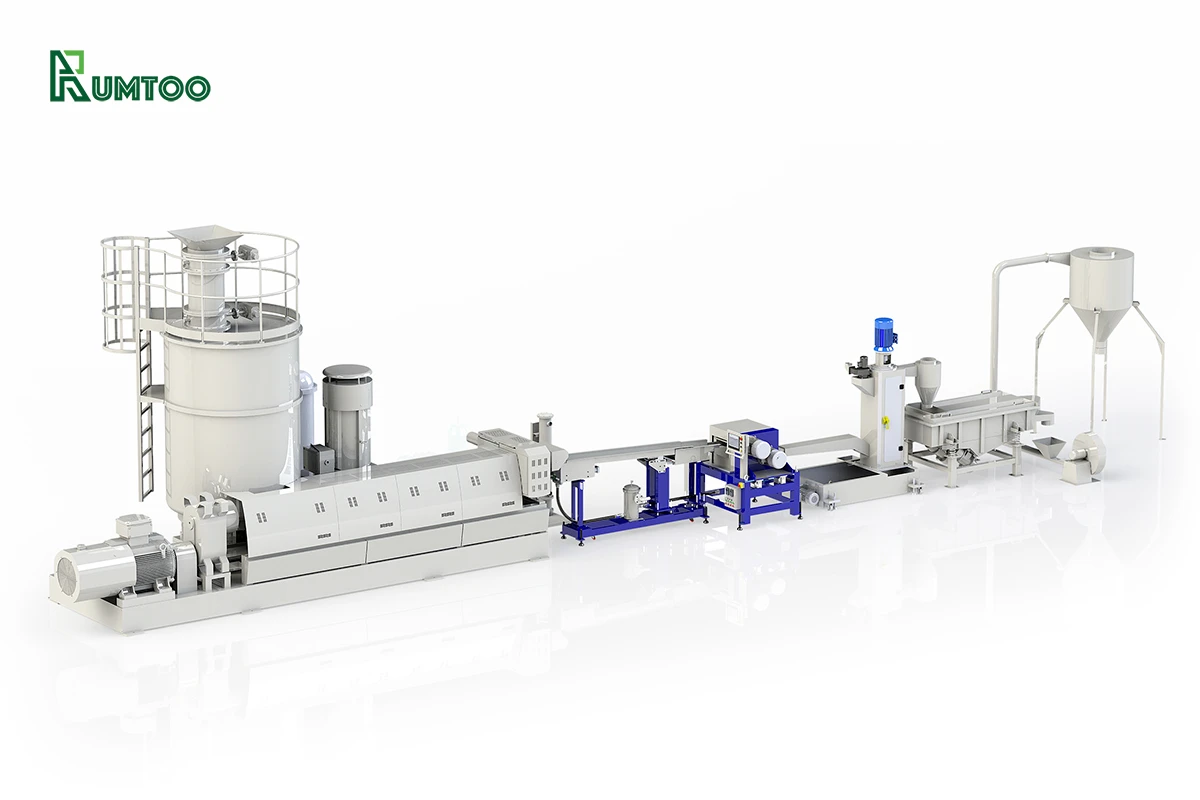

Advanced Plastic Pelletizing Machine

Convert plastic waste into consistent, high‑value pellets. Our line delivers stable throughput, low melt degradation, and minimal downtime for both post‑industrial and post‑consumer recycling.

Key Features & Benefits

Advanced Degassing

Triple vacuum zones remove moisture and volatiles, protecting melt quality and pellet appearance.

Integrated Cutter‑Compactor

Homogenizes density and stabilizes the feed for high throughput and fewer jams.

Automatic Pelletizing

Closed‑loop control maintains pellet size, reducing operator workload and waste.

Uptime & Safety

Safety interlocks, overload protection, and quick‑swap screen changer maximize uptime.

Material Flexibility

Handles HDPE/LDPE/LLDPE/PP/BOPP with appropriate pre‑treatment for P.I. and P.C. streams.

Energy Efficient

Optimized motors and system logic lower kWh/ton without sacrificing performance.

Process Flow

1. Feeding

Conveyor feeds raw material into the cutter‑compactor.

2. Densification

Cutter‑compactor homogenizes material and stabilizes density.

3. Extrusion

Single‑screw extruder melts and mixes the plastic.

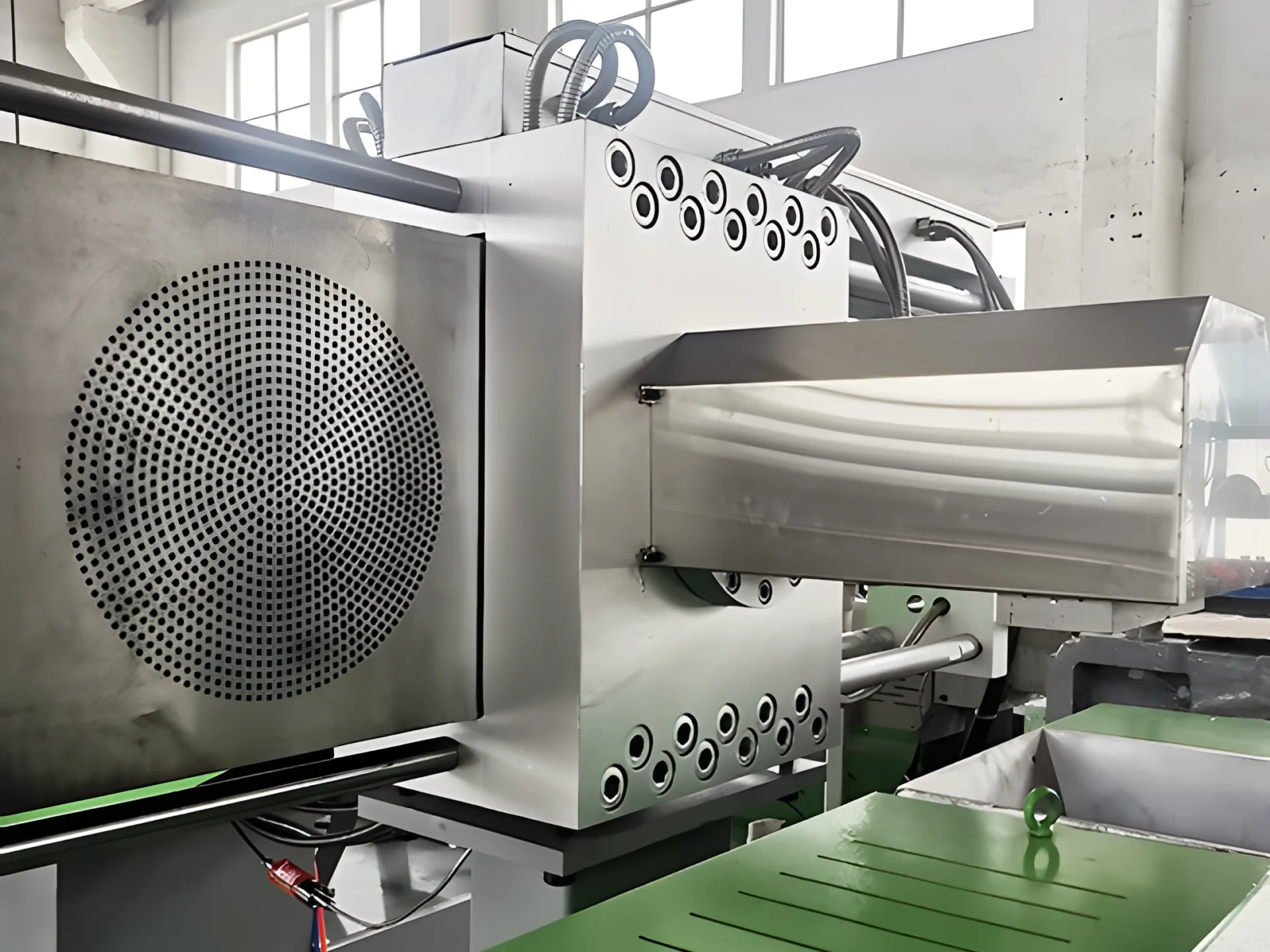

4. Degassing

Triple vacuum zones extract ink, moisture and volatiles.

5. Pelletizing

Water‑ring pelletizer creates uniform pellets with closed‑loop control.

6. Drying

High‑speed dewaterer prepares pellets for storage.

7. Storage

Pellets transfer to silos or big‑bag stations for collection.

Machine Components

Technical Specifications

| Parameter | Value |

|---|---|

| Throughput | 300 – 2000 kg/h |

| Degassing | Triple vacuum zones |

| Pelletizing | Water‑ring system, closed‑loop |

| Materials | HDPE, LDPE, LLDPE, PP, BOPP |

| Screen Changer | Automatic continuous |

| Power Supply | 380V / 50Hz (customizable) |

Frequently Asked Questions

What materials does this line support?

HDPE/LDPE/LLDPE/PP/BOPP, both post‑industrial and post‑consumer (with proper pre‑washing and sorting). Film, raffia and rigid flakes are supported.

How do you keep pellet size consistent?

The water‑ring pelletizer has automatic pressure and speed feedback to maintain pellet size with minimal intervention.

Will moisture and ink cause defects?

Triple degassing removes moisture and volatiles; filtration and screen change handle solids and inks.

Can I upgrade capacity later?

Yes. We can upsize extruder diameter, motor power and downstream while keeping line balance and quality.

Ready to turn plastic waste into value?

Tell us your material and target capacity. We’ll configure the optimal pelletizing line for you.

Get Your Custom Quote