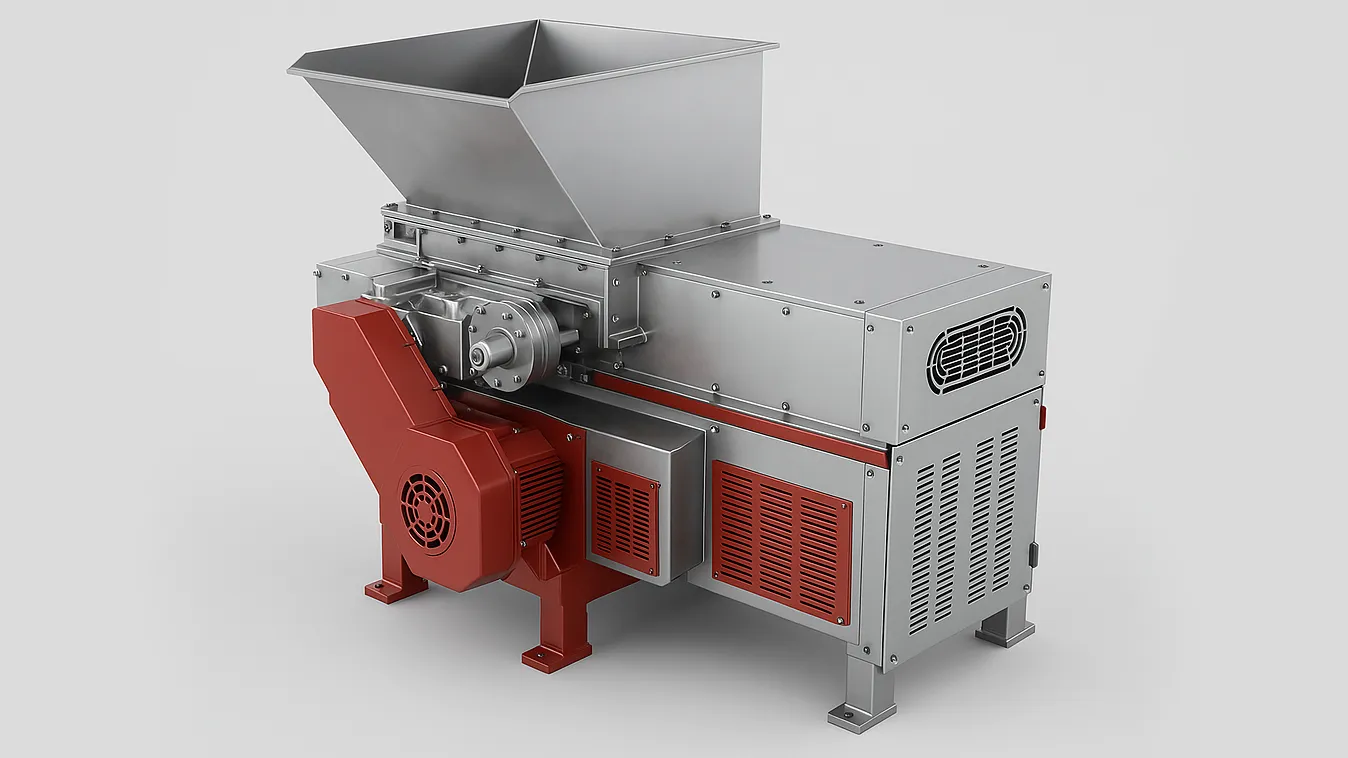

High-Efficiency Industrial Plastic Shredder: Transform Plastic Waste into Reusable Resources

Our advanced recycling machine efficiently shreds and processes waste plastics, converting them into high-quality, reusable raw materials for your production line.

Get a Quote NowWhy Choose Our Machine?

High Throughput

Process up to 2 tons of plastic per hour, maximizing your operational efficiency.

Durable Blades

Hardened alloy steel blades ensure long life and consistent performance with minimal maintenance.

Energy Efficient

Optimized motor and drive system reduces power consumption, lowering your operational costs.

Smart & Safe

PLC control with auto-reverse anti-jamming system ensures safe and smooth operation.

Stop Burning Money, Start Earning It

Turn common waste management headaches into profitable opportunities.

The Problem

- Sky-high disposal fees for bulky plastic scrap.

- Risk of environmental fines for improper waste handling.

- Valuable materials occupying expensive floor space.

Our Solution

- Shred waste to reduce volume, drastically cutting disposal & transport costs.

- Create high-quality, uniform granules to sell as raw material.

- Achieve compliance and turn a cost center into a revenue stream.

Simple 4-Step Process

Visually understand how our equipment turns complex waste into simple, valuable material.

1. Feed Material

Load bulk plastic waste, films, or lumps into the feeding hopper.

2. Shredding

High-torque blades shred the material into smaller, uniform pieces.

3. Screening

A mesh screen controls the output size for consistent particle quality.

4. Collection

Processed material is discharged, ready for reuse or further processing.

Technical Excellence

Engineered for performance and reliability. Here are the details that matter to your technical team.

Heavy-Duty Gearbox

Provides stable, high-torque power transmission for shredding tough materials without failure.

Siemens PLC Control

Intuitive interface for easy operation, monitoring, and automatic overload protection.

Easy-Access Chamber

Designed for quick screen and blade changes, minimizing downtime during maintenance.

| Specification | Model R-500 | Model R-800 | Model R-1200 |

|---|---|---|---|

| Motor Power | 37 kW | 55 kW | 90 kW |

| Rotor Diameter | 500 mm | 800 mm | 1200 mm |

| Capacity (kg/hr) | 500 – 800 | 800 – 1500 | 1500 – 2500 |

| Final Particle Size | 20 – 50 mm | 20 – 50 mm | 20 – 50 mm |

| Weight (kg) | 3500 | 5200 | 7800 |

See It In Action

From industrial scrap to post-consumer packaging, our machine handles a wide variety of plastic materials.

Versatile Applications Across Industries

Our shredders are engineered for flexibility, adding value to a wide range of operational workflows.

In-house Recycling

Process manufacturing scrap (e.g., injection molding rejects, film trim) on-site to be immediately reintroduced into production.

Commercial Recycling

Handle post-consumer and post-industrial plastics like bottles, containers, and packaging for resale to manufacturers.

Waste-to-Energy Prep

Shred and prepare plastics into a consistent feedstock for pyrolysis or gasification plants, creating alternative fuels.

Secure Destruction

Destroy off-spec products, counterfeit goods, or sensitive materials to protect your brand and intellectual property.

Trusted by Industry Leaders

“The shredder has been a game-changer. Our disposal costs are down 60%, and we’re now selling the granulated material for a profit. The machine is a workhorse.”

“We were struggling with inconsistent particle size from our old equipment. This machine delivers exactly what we need for our extrusion process. The reliability is outstanding.”

Get a Custom Solution & Quote

Tell us about your material and capacity needs, and our experts will configure the perfect machine for you and provide a detailed, no-obligation quote.

Frequently Asked Questions

What types of plastic can this machine process?

Our machine is designed to handle a wide range of plastics, including HDPE, LDPE, PP, PET, and PVC, in various forms like bottles, films, pipes, and purgings.

What is the lead time for delivery?

Standard models typically have a lead time of 4-6 weeks. Custom configurations may require 8-10 weeks. Please contact us for a precise schedule based on your order.

Do you provide installation and training?

Yes, we offer comprehensive on-site installation, commissioning, and operator training services to ensure your team can operate the equipment safely and efficiently.

What is the warranty period?

All our machines come with a standard 12-month warranty covering all parts against manufacturing defects. Extended warranty options are also available.