Industrial Double Shaft Shredder

Transform bulky, difficult-to-process waste into uniform, manageable material. Our industrial shredders are the cornerstone of high-volume recycling, engineered for maximum throughput and reliability with minimal downtime.

- High-torque, low-speed design

- Shreds plastics, tires, e-waste & more

- Robust and durable construction

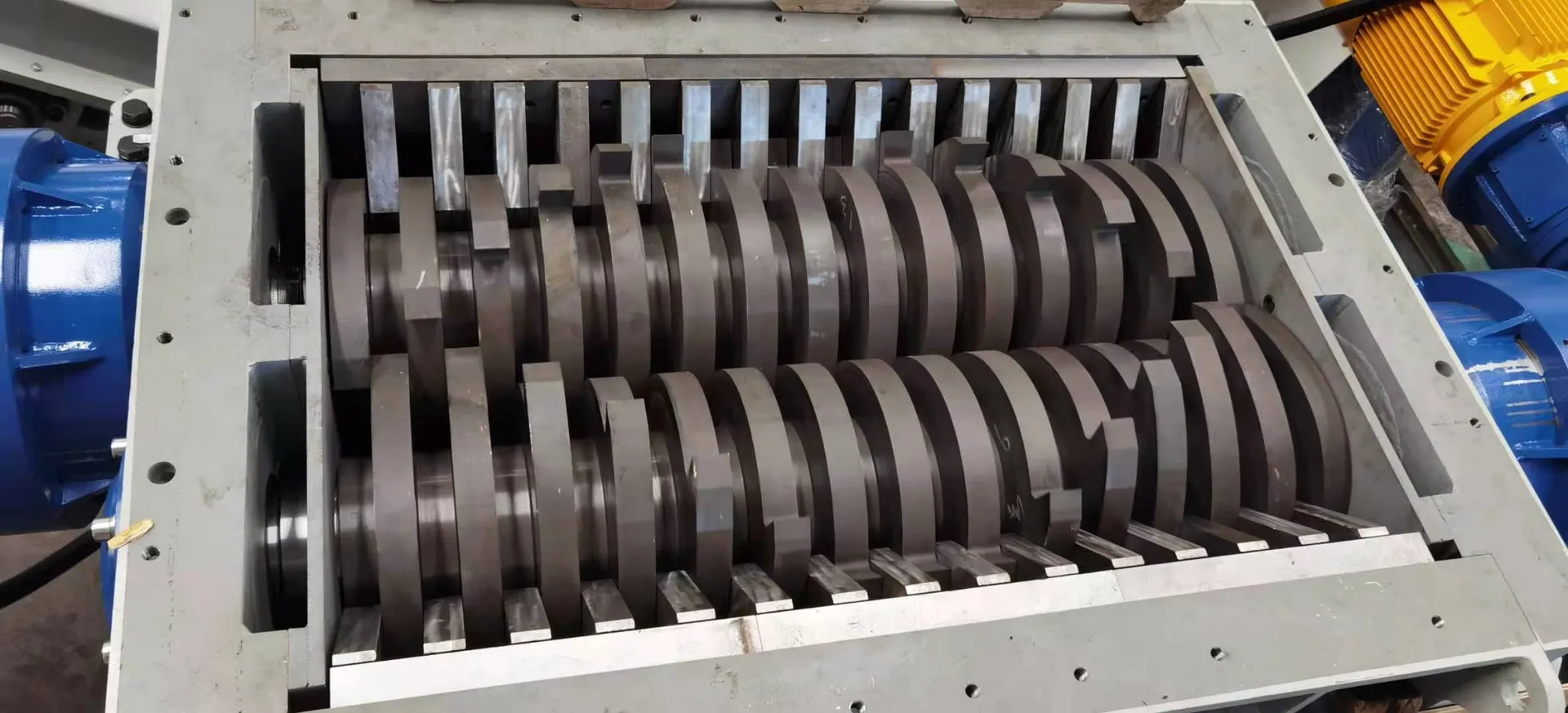

Working Principle: High Torque, Low Speed

The Double Shaft Shredder operates on a simple yet powerful principle. Two hexagonal shafts, mounted with heavy-duty hooked shear blades, rotate slowly into each other. This high-torque motion grabs and pulls material into the cutting chamber, shearing it between the blades. This robust, low-speed design allows the shredder to:

- Quietly and effectively process large, tough, or high-volume feedstock.

- Produce consistently sized output pieces (typically 25-125mm).

- Generate minimal dust and noise for a safer working environment.

Core Advantages

Engineered for maximum uptime, safety, and operational flexibility.

High-Torque Power

Delivers immense cutting force at low speeds to shred tough, bulky materials without jamming.

Durable Alloy Blades

Hardened alloy steel blades are wear-resistant and can be re-sharpened, ensuring long life and low running costs.

Overload Protection

An automatic reverse function protects the drive system from damage when encountering non-shreddable objects.

Low Noise & Dust

The low-speed operation significantly reduces noise levels and dust generation, creating a safer work environment.

Versatile Applications & Materials

Our shredders are trusted across numerous industries for their power and reliability. Key applications include:

Plastic & Rubber Recycling

Effortlessly processes plastic bales, purgings, car bumpers, and tires into uniform strips for further granulation.

E-Waste & Data Destruction

Securely destroy hard drives, circuit boards, and other electronic components, ensuring data security and material recovery.

Metal Scrap Reduction

Ideal for shredding light metal scrap, including aluminum profiles, UBCs (Used Beverage Cans), and sheet metal offcuts.

Industrial & Bulky Waste

Reduces the volume of bulky items like furniture, mattresses, textiles, and industrial drums for easier disposal or recycling.

Wood & Biomass

Processes scrap wood, pallets, and green waste into chips suitable for biomass fuel or secondary processing.

Secure Document Shredding

Provides high-volume, reliable destruction of paper, cardboard, and sensitive documents for commercial shredding services.

Machine Gallery

A closer look at the robust construction and key components of the Double Shaft Shredder.

Shredder in Action

Watch how our Double Shaft Shredder effortlessly processes various challenging materials.

Technical Specifications

We offer several models to match your specific capacity and material requirements. Custom configurations are available upon request.

| Specification | SSJ400-800 | SSJ400-1200 | SSJ450-800 | SSJ450-1200 |

|---|---|---|---|---|

| Motor Power | 2 × 22 kW | 2 × 30 kW | 2 × 30 kW | 2 × 45 kW |

| Number of Blades | 16 / 26 | 24 / 40 | 16 / 26 | 24 / 40 |

| Rotating Speed (RPM) | 25 / 35 | 25 / 35 | 18 / 28 | 18 / 28 |

| Approx. Capacity | 1,500 kg/h | 2,500 kg/h | 3,000 kg/h | 4,000 kg/h |

Why Choose Our Shredder?

A clear comparison against traditional high-speed granulators for primary size reduction.

| Feature | Rumtoo Double-Shaft Shredder | Traditional High-Speed Granulator |

|---|---|---|

| Best Use Case | Primary shredding of bulky, tough materials | Secondary size reduction of pre-shredded material |

| Input Material Size | Large, unsorted items (bales, tires, drums) | Requires smaller, more uniform pieces |

| Operating Principle | High-torque, low-speed shearing action | High-speed impact cutting |

| Dust & Noise Level | Low dust and noise generation | Higher dust and noise levels |

Frequently Asked Questions

What is the typical output particle size?

The output size depends on the blade width. Our double-shaft shredders typically produce rough strips between 25mm and 125mm wide. For a smaller, more uniform particle size, the shredder is often used as a primary step before a secondary granulator.

Can this shredder handle metal contamination?

While it can shred soft metals like aluminum, it is primarily designed for materials like plastic, wood, and e-waste. The automatic reverse system helps protect against damage from occasional, small, hard contaminants, but frequent processing of heavy metal is not recommended.

What is the maintenance schedule for the blades?

Blade maintenance depends on the material being processed. We recommend weekly visual inspections. The blades are made from high-wear-resistant alloy steel and can be rotated and re-sharpened multiple times before needing replacement, ensuring low operational costs.

Configure Your Shredding Solution

For the latest pricing, lead times, and to discuss a custom configuration for your business, send us a message. Our engineering team will help you select the right model, blade configuration, and options for your specific application.

- All machines come with a 1-year limited warranty.

- On-site installation and training available.

- Lifetime technical support and spare parts service.