Horizontal Debaler Machine for Plastic Bales

The essential first step for an automated recycling line. Our Horizontal Debaler Machine efficiently breaks apart compacted bales of PET, HDPE, and other rigid plastics, creating a steady, free-flowing material stream. Eliminate costly manual labor, prevent bottlenecks, and significantly increase your line’s overall throughput and profitability.

描述

Automate Your Baled Plastic Opening Process

Introducing the Horizontal Debaler Machine, the cornerstone of an efficient recycling line. Effortlessly break apart compacted bales of PET and HDPE bottles, replacing costly manual labor and ensuring a steady, free-flowing stream of material to your system.

Why a Debaler is Essential for Your Operation

Dramatically Reduce Labor Costs

Automate the bale-breaking process and significantly lower operational costs by replacing expensive and inefficient manual labor.

Increase Throughput

Ensure a consistent, free-flowing stream of material to your subsequent recycling machines, preventing bottlenecks and maximizing overall line capacity.

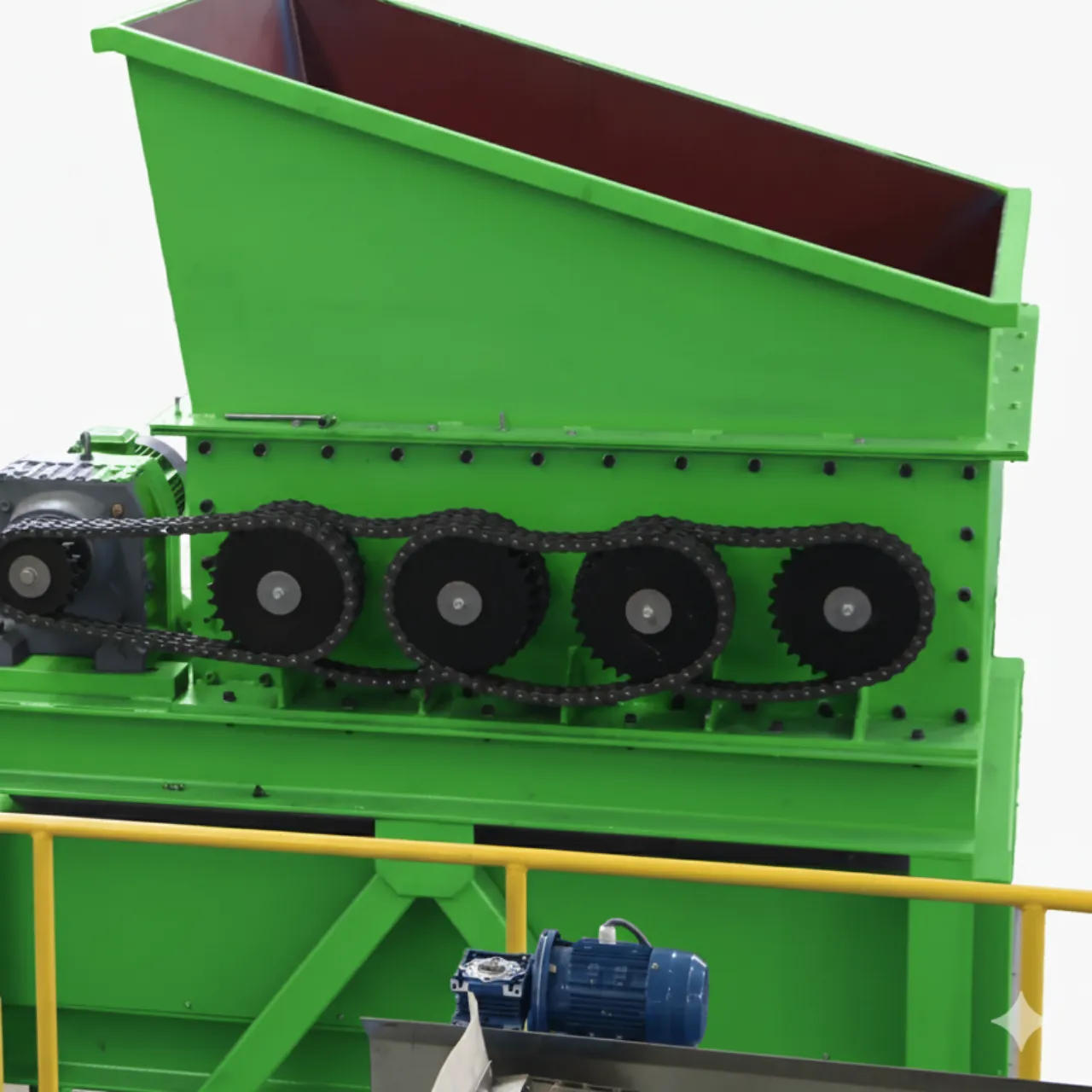

Simple & Effective Design

Utilizes a robust system of rotating hooks to reliably grapple and loosen compacted rigid plastics like PET and HDPE bottles with minimal maintenance.

Simple Principle, Powerful Results

The working principle is straightforward. After the bale wires are manually cut, the entire compacted bale is loaded into the debaler. Inside, powerful rotating hooks grapple and tear at the compacted material, effectively “busting” the bale apart. The loosened bottles and containers then fall freely onto a conveyor below, ready for the next stage of recycling.

Suitable Materials

This machine is specifically designed for rigid plastics such as baled PET bottles, HDPE bottles, milk jugs, containers, and other similar items.

Important Note on Unsuitable Materials

Please be aware that our horizontal debaler is NOT suitable for opening bales of plastic film. The film will tangle in the rotating hooks, causing damage and operational downtime. For breaking film bales, we recommend using a single-shaft shredder.

Technical Specifications

| Feeder Dimensions | 1450mm x 1650mm |

| Main Motor Power | 5.5 kW |

| Conveyor Motor Power | 7.5 kW |

| Warranty | 1-Year Limited Warranty |

*Specifications can be customized to fit your specific bale sizes and throughput requirements. Contact us to discuss your project.

Automate Your Infeed, Cut Your Costs

Ready to make your recycling line more efficient and cost-effective? Contact us for the latest prices, lead times, and a customized quote on our Horizontal Debaler Machine.

Frequently Asked Questions

Do I still need to manually cut the bale wires before feeding?

Yes. The Horizontal Debaler is designed to break apart the compacted plastic material itself, not to cut the high-tensile metal wires that hold the bale together. You will need to manually cut and remove the wires before loading the bale into the machine.

What is the typical throughput or capacity of this machine?

The capacity is not measured in kg/h like other machines, but rather in “bales per hour”. It’s designed to easily keep pace with recycling lines of up to 2000 kg/h or more, ensuring the downstream equipment is never starved of material. The key benefit is creating a consistent flow, not processing at a fixed rate.

Can this machine handle wet or dirty bales?

Absolutely. The machine’s robust design with powerful hooks is highly effective at breaking apart bales regardless of whether they are wet or contain dirt and debris. This is a common condition for post-consumer bales, and our debaler is built to handle it.

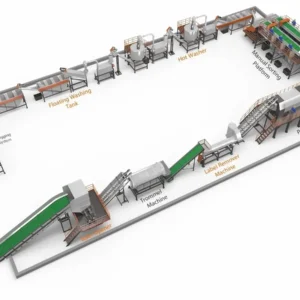

How does it connect to the rest of my recycling line?

Typically, the debaler is positioned at the very beginning of the line. It is loaded with a forklift, and the machine’s output chute is placed directly over an inclined conveyor belt. As the material is loosened, it falls onto this conveyor, which then transports it to the next machine, such as a trommel screen or a manual sorting station.