Desktop 3D Filament Production Line

Take control of your 3D printing materials with our Mini 3D Filament Extruder Line. This compact, high-precision desktop machine empowers you to create custom filament from a wide range of plastics like PLA, ABS, and PETG. Perfect for R&D, education, and makers who want to experiment with custom colors and recycled materials.

描述

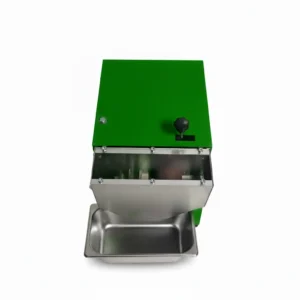

Mini 3D Filament Extruder Line for Desktop

Unleash your creativity with our Mini 3D Filament Extruder Line. This compact system empowers you to turn plastic pellets—virgin, recycled, or custom-blended—into high-quality, usable filament right on your desktop. Experiment with colors, materials, and formulations like never before.

Engineered for Makers, Labs, and Innovators

Endless Experimentation

Create custom colors with masterbatch, test new polymer blends, or recycle your own plastic scraps into usable filament. The possibilities are limitless.

Precision Engineering

Features a high-quality 38CrMoAl screw and barrel with precise temperature control, ensuring consistent extrusion for high-tolerance filament production.

Compact & Quiet

With its small footprint and silent cooling device, this extruder is designed to fit perfectly in a workshop, lab, or office environment without disruption.

The Simple Path From Pellet to Filament

1. Feed Your Material

Pour your plastic pellets (PLA, ABS, PETG, etc.) and colorants into the feeding hopper.

2. Melt & Extrude

The screw melts and pressurizes the plastic, pushing a consistent strand of molten filament through the nozzle.

3. Cool & Spool

The extruded filament is then cooled and wound onto a spool using downstream equipment (puller and winder sold separately).

High-Quality Filament Samples

Technical Specifications

Model: SJ25 Mini Extruder

| Screw Diameter | 25mm |

| Design Capacity | 0.1 – 2 KG/h |

| Machine Dimensions | 0.76 x 0.2 x 0.5 m |

| Motor Power | 250W |

| Voltage | 220V (customizable) |

| Heating Temperature | Room Temp to 350°C |

| Screw & Barrel Material | 38CrMoAl (Nitrided Steel) |

Bring Your Filament Ideas to Life

Ready to take control of your material supply? Contact us for pricing, availability, and to learn more about our complete desktop filament production solutions.

Frequently Asked Questions

What materials can I use with this extruder?

This machine is highly versatile and can process a wide range of thermoplastics, including PLA, ABS, PETG, HIPS, PC, and more. It’s perfect for using virgin pellets, pre-shredded recycled plastic, or creating custom composite materials.

Is this a complete “production line”? What else do I need?

This product is the core extruder. To create a complete filament production line, you will also need downstream equipment: a filament puller to maintain consistent diameter and a winder/spooler to collect the finished filament. We can provide information on compatible solutions.

How do I control the filament diameter (e.g., 1.75mm or 2.85mm)?

The final diameter is a result of three main factors: the nozzle size on the extruder, the extrusion speed (set by the motor RPM), and the speed of your filament puller. By carefully balancing these variables, you can achieve highly precise filament tolerances.

Is it difficult for a beginner to use?

The machine itself is designed for user-friendly operation. However, like any precision process, there is a learning curve to mastering filament production. You will need to experiment with temperature, speed, and cooling settings to “dial in” the perfect parameters for each specific material you use.