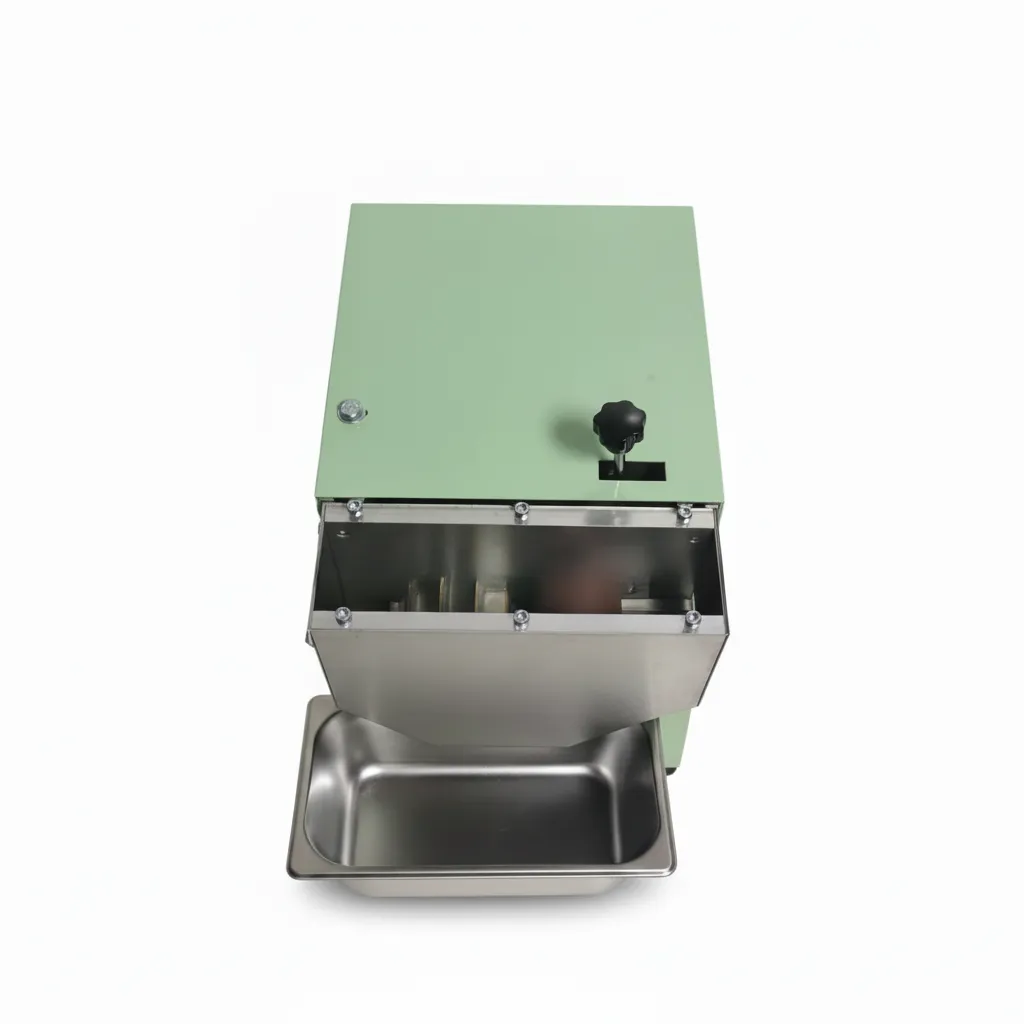

Mini Desktop Plastic Pellet Cutter

Transform extruded plastic strands into high-quality, uniform pellets with our Mini Desktop Pellet Cutter. Engineered for precision and reliability, this compact machine is the perfect companion for laboratory extruders, material testing, and small-scale recycling. Featuring adjustable speed control and durable alloy steel blades, it delivers consistent results for R&D and educational applications.

描述

Mini Desktop Plastic Pellet Cutter

Engineered for precision pelletizing in laboratory and R&D settings. Effortlessly transform extruded plastic strands into uniform, high-quality pellets.

Core Advantages

Precision & Uniformity: Delivers clean, consistent cuts, producing pellets of uniform size and shape crucial for material testing and reprocessing.

Compact & Desktop-Friendly: Its small footprint makes it a perfect fit for any lab bench, integrating seamlessly with small-scale extruders.

Durable Blades: Equipped with high-hardness alloy steel blades for long-lasting performance and minimal maintenance.

Adjustable Speed Control: Variable speed motor allows precise control over pellet length, adaptable to different materials and requirements.

How It Works: A Simple 3-Step Process

1. Feed the Strand

Guide the cooled, solidified plastic strand from your extruder into the pelletizer’s protected inlet.

2. Adjust & Cut

Set the desired cutting speed. The high-speed rotating blade works against a fixed blade to shear the strand cleanly.

3. Collect Pellets

Uniform pellets are neatly discharged into a collection bin, ready for drying, analysis, or reuse.

Features & Technical Specifications

*Note: Parameters are for reference only and can be customized to meet specific production requirements.

Frequently Asked Questions

What types of plastics can this pellet cutter handle?

It is designed for most common rigid thermoplastics like PLA, ABS, PETG, PS, PP, and PE. The strand must be sufficiently cooled and solidified before entering the cutter.

How is the pellet length controlled?

The length of the pellets is determined by the combination of the strand’s infeed speed (usually controlled by a puller) and the rotational speed of the cutter’s blades, which is adjustable on the machine.

Is the machine safe and easy to maintain?

Yes. It features a fully guarded cutting chamber to prevent accidents. Maintenance is simple, involving periodic cleaning of the cutting area and blade inspection. Blades are designed for easy replacement.

The perfect companion for your lab extruder, ensuring consistent, high-quality pellets for material recycling, compounding, and R&D.