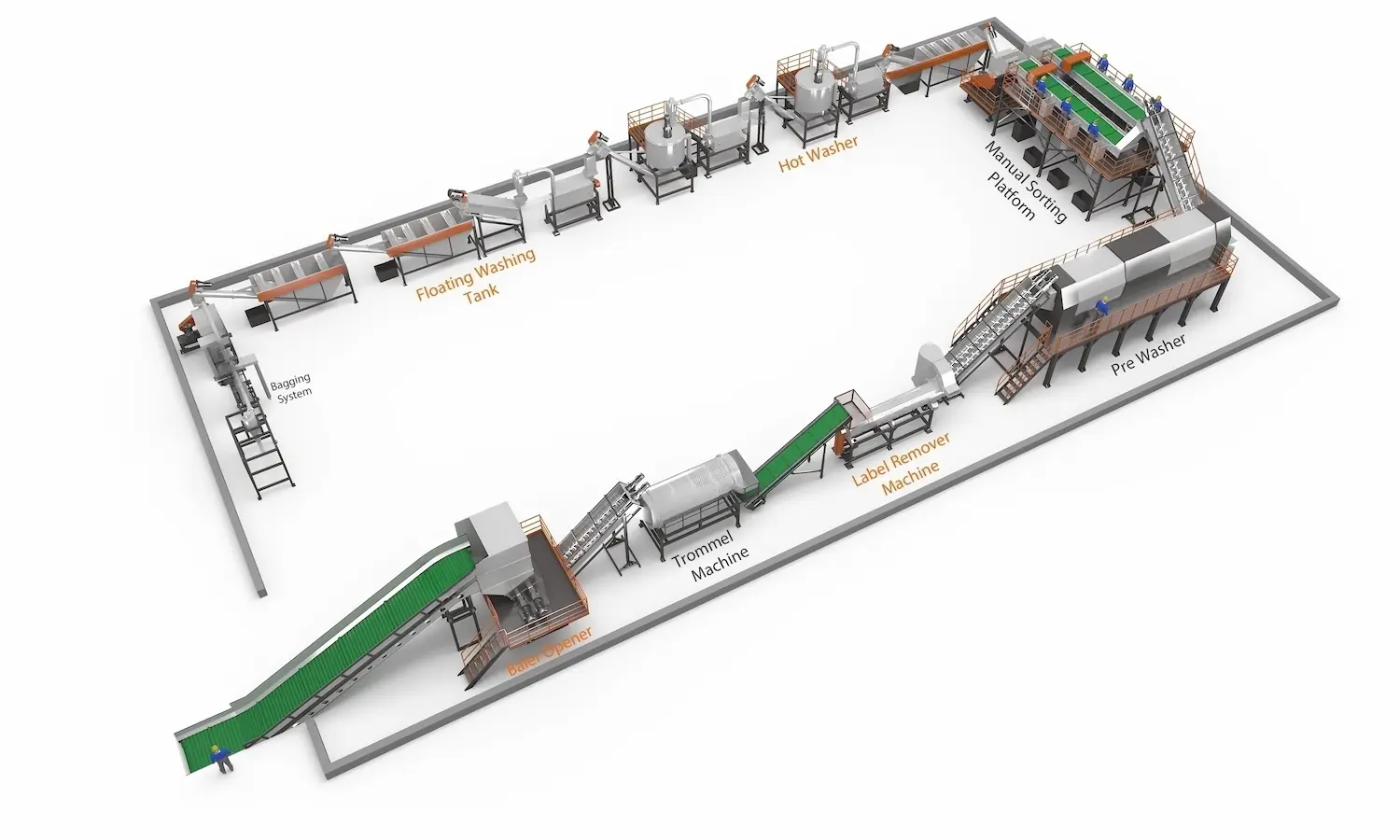

PET Bottle Washing Line

Rumtoo Recycling’s PET bottle washing line provides a complete solution for converting dirty PET bottle bales into clean flakes suitable for polyester fiber production or pelletizing. Our fully automatic systems feature integrated machinery controlled by a central panel and come with professional installation and warranty.

描述

PET Bottle Washing Line

Complete solutions for recycling PET bottles into clean flakes

Description

Our standard PET bottle washing line is your complete solution for turning dirty bales of PET bottles into clean PET flakes ready for usage in producing polyester staple fiber or further processing into plastic granules via pelletizing. We offer standard washing capacities from 500kg/h up to 3000kg/h and can also manufacture custom wash lines with greater capacities.

Rumtoo’s PET recycling line is fully automatic where each piece of recycling machinery is connected via the use of either belt or screw conveyors. In addition, the entire washing line is controlled via a central electric control panel and cabinet.

PET Bottle Washing Line Machinery

Debaler Machine

As PET bottles (with caps & labels) often come in bales, compacted bundles tied together with metal wires, the first stage is to get the material into a “free flowing” stream. The “debaler” breaks apart the bales allowing the plastic bottles within to drop onto the belt conveyor that moves the bottles onto the next step. Learn more about our debaler machine.

Trommel Separator

A large, slow rotating machine used to remove small pieces of contamination. At the core of the trommel separator is a large mesh screen tunnel that rotates between 6-10 rotations per minute. The holes on this tunnel are small enough so the PET bottles will not fall through, however, large enough so small particles of contamination will. Learn more about our trommel separator.

Wet Granulator / Crusher

The bottles are cut into “flakes”, or small pieces, via our wet granulator. Simply put, a granulator uses an open rotor mounted with heavy-duty knives that spin at high speeds. As the PET bottles enter the granulator’s cutting chamber, these rotating knives come into contact with stationary knives cutting the bottles into small pieces. A screen with small holes between 12-18mm in diameter is used to control the size of the flakes; That is, the PET plastic will continue to be cut within the chamber until it is small enough to fall through the holes on this screen. All the while, water is sprayed into the cutting chamber partially washing the bottles while acting as a lubricate to reduce friction of the knives and plastic. Learn more about our wet granulator

Label Separator

The stream of plastic leaving the granulator is composed of PET flakes, paper and PP/PE/PVC film from the labels, and PP/PE rigid plastics from the bottle caps. This mixed stream is now ready to be sorted. The first step is the label separator where a column of pressured air blows away the lighter paper and plastic film into a separate collection tank. Learn more about our label separator.

Sink / Float Separation Tank

A large tank of water used to separate materials that sink from those that float. This is the final separation equipment in our PET bottle washing line that effectively removes the left over plastic films from labels and PP/PE bottles caps. As both the labels and bottle caps float in water, the sinking PET flakes can easily be removed to be further processed in the next piece of equipment. Learn more about our sink float separation tank.

Hot Washer For PET Flakes

Similar to a washing machine in nature, this stream of PET flakes are washed using boiling hot water which sterilizes and further gets rid of contaminants such as glues (from the labels being glued on), grease/oils, and difficult to remove left-overs (beverage/foods) from the equation. Learn more about our Hot Washer For PET Flakes.

Friction Washer

A secondary friction washer (cold water) is used to cool and further clean the PET flakes in a scrubbing manner. Learn more about our friction washer.

High Speed Dewatering Machine

The dewatering machine uses centrifugal or “spinning” force to remove a portion of the water from the PET flakes. It’s a cost-effective way to dry the PET flakes before it’s thermally dried. Thermal drying consumes much more energy. Learn more about our dewatering machine.

Thermal Dryer + Cyclone Separator

The partially dried PET flakes can now be completely dried using the thermal dryers. Within the long tubes of the thermal dryers, hot air and the PET flakes are mixed together where the leftover moisture is dehydrated. The final cyclone separator mixes the hot, moist air with a flow of cold air cooling the PET flakes in preparation for storage. The cyclone separator is also the last defence against fines such as dust. Learn more about our thermal dryer.

Product Silo

A large storage tank for the clean, dry PET flakes.

Pelletizer / Extruder

As most PET bottle recycling lines are used to produce clean flakes for use directly in producing polyester staple fibre, we leave the pelleizing equipment as an optional piece in our washing line. Rumtoo offers both single-screw and double-screw extruders for this purpose. Learn more about our pelletizing equipment.

Models & Specifications

| Input Capacity | 500 kg/h | 1000 kg/h | 1500 kg/h | 2000 kg/h |

|---|---|---|---|---|

| Dimension [LxWxH] | 45mx15mx6m | 50mx15mx6m | 55mx16mx6m | 60mx18mx6m |

| Operators | 4-5 people | 5-6 people | 6-8 people | 8-10 people |

| Installation Power | 180KW | 299KW | 370KW | 450KW |

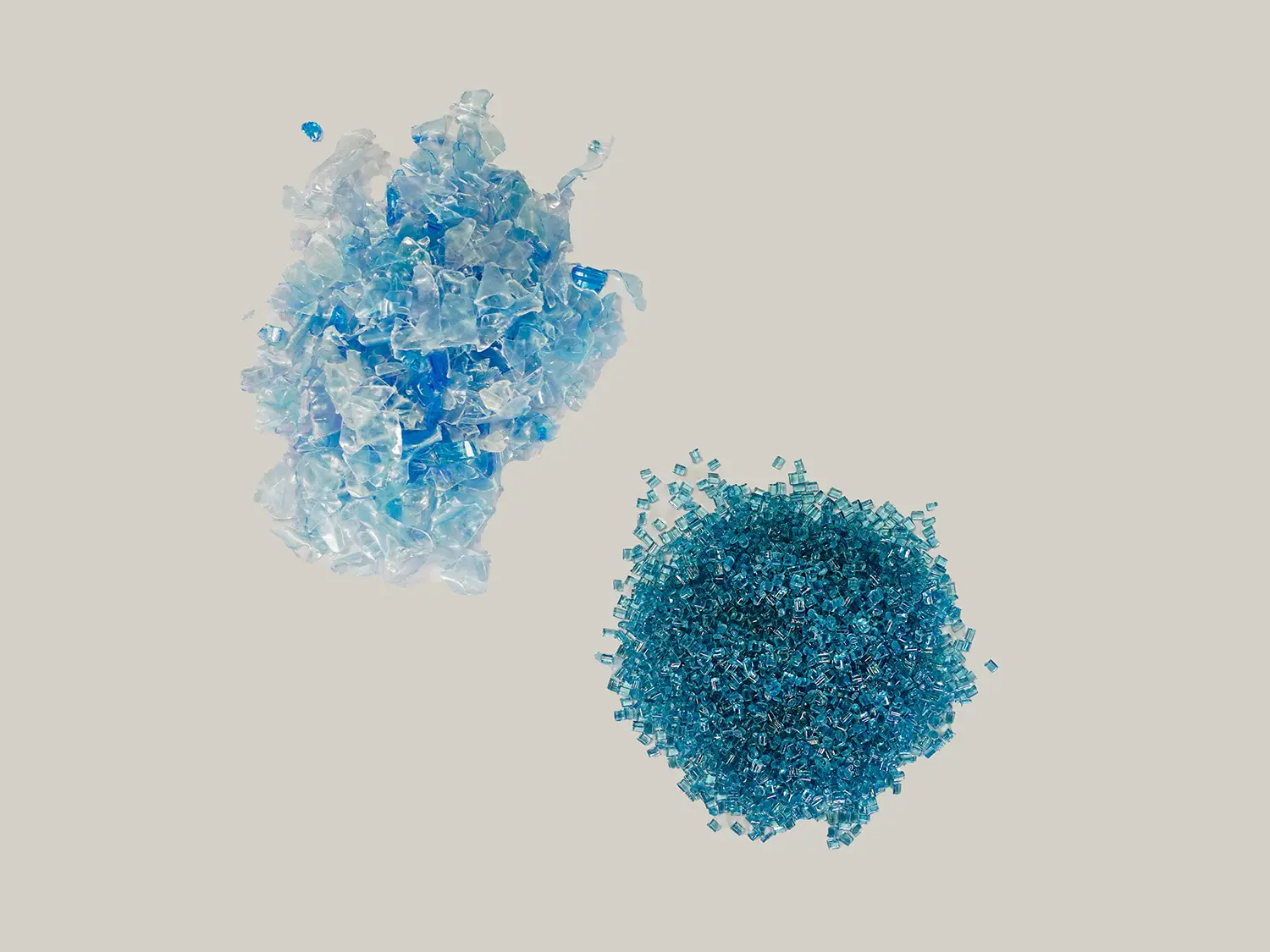

PET Flakes

We understand the importance of producing high quality PET flakes that not only clean, but are also low in contamination. In order to continually evolve and improve our PET bottle washing lines, Rumtoo Recycling has implemented a customer feedback system where samples of PET flakes from customers using our washing lines are taken and placed in our laboratory for testing. Based on the many samples we received last year, we are confident our PET washing lines can achieve the following benchmarks:

- Moisture: < 1%

- Bulk density: < 0.3G/CM3

- Total impurity: < 100ppm

- PVC content: < 40ppm

- Metal content: < 10ppm

- PE/PP content: < 50ppm

- Particle size: < 14-16mm

*Feel free to contact us if you have additional requirements.

Custom PET Bottle Recycling Lines

Depending on contaminants within the PET bottle bales, additional equipment maybe required such as a separation table for manual sorting, metal detectors and removal, PVC heat separation, and more. Rumtoo offers custom tailored PET washing lines based on your specifications. Let us know your needs including capacity, type of PET bottles and how it is packaged, and types of contaminants you are expecting and let our professional team of engineers handle the rest.

Installation & Warranty

An installation package comes standard with our washing lines where our engineers (one electrical and one mechanical) will travel to your facility and install the washing line for you. We also offer routine maintenance teams as well as operations consultants that can ensure the PET recycling lines your purchase will run smoothly year and year.

All equipment from Rumtoo Recycling comes with detailed operation instructions as well as an installation guide. A list of required replacement parts will also be provided at the time of purchase. All machinery and parts are warranted against manufacturer defects and come with a 1 year limited warranty.

Additional Images

Place An Order

The general lead time for all single-piece, standard equipment orders is 30 days. For custom orders or complete washing lines, the lead time is between 60 – 90 days. The actual lead time will depend heavily on the complexity of the project as well as the amount of machinery we have in queue at the time of your order.

Ready to discuss your PET recycling needs?

Contact us to discuss pricing and ordering details.