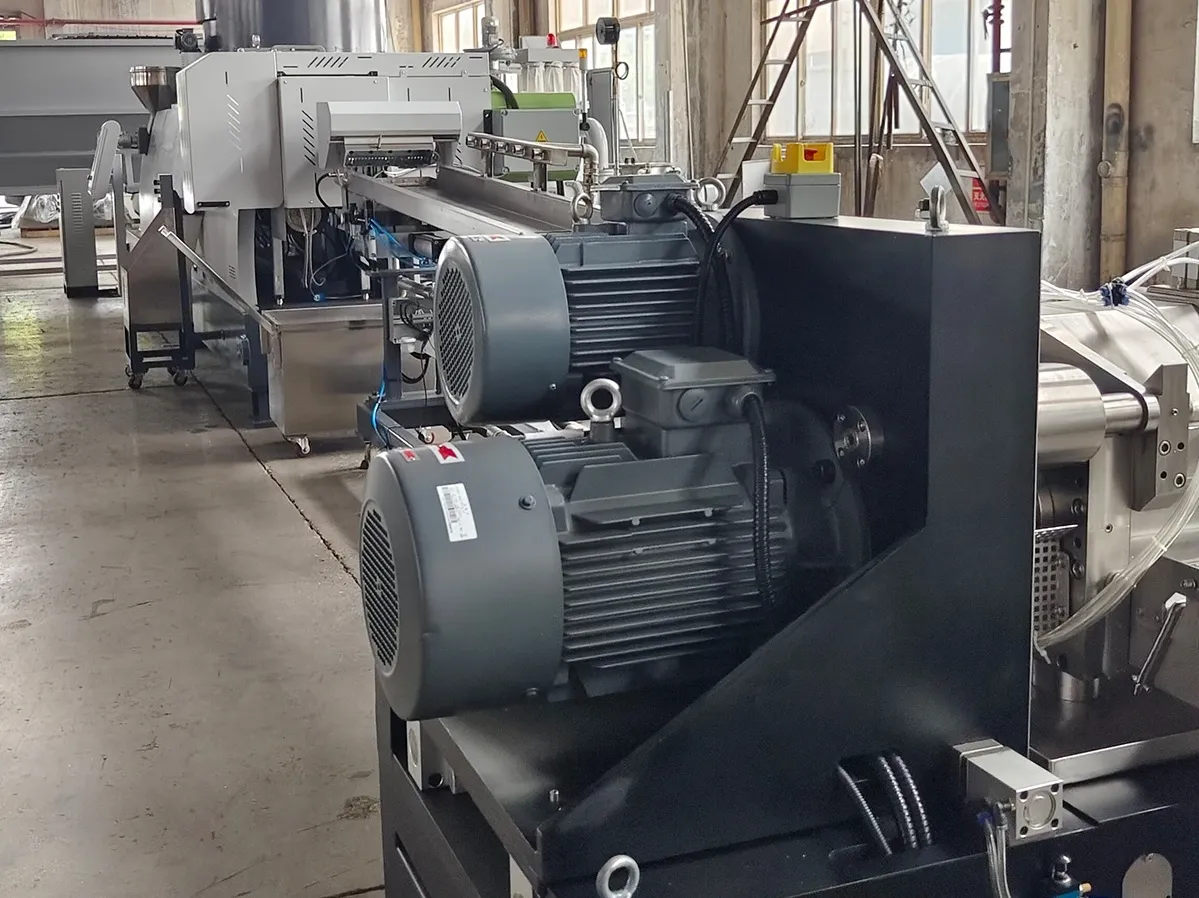

Industrial Pelletizing Line for Rigid Plastics

Process pre-crushed hard plastics like HDPE, PP, and ABS into valuable, uniform pellets. Our line features Heat Wave Stabilization™ technology to ensure consistent quality and profitable recycling.

- High-throughput force-feeding

- Uniform pellets with Heat Wave Stabilization™

- Superior wear resistance for long life

See It In Action

Watch our rigid plastic pelletizing line transform scrap flakes into high-quality, uniform pellets, ready for your production line.

Engineered for Crushed Flakes and Regrind

Optimized Force-Feeding System

Engineered for rigid flakes, our vertical force-feeder prevents material bridging and ensures a consistent, high-volume flow for maximum throughput.

Heat Wave Stabilization™

Our proprietary technology guarantees exceptionally uniform heat distribution, gently melting the flakes without degradation to produce consistent, high-quality pellets.

Superior Wear Resistance

Built with gas-nitrided 38CrMoAlA steel, the barrel and screw resist abrasion from rigid plastics, ensuring a long and reliable service life.

From Flakes to Pellets

Our streamlined process ensures maximum efficiency and pellet quality.

Pre-crushed and cleaned plastic flakes are loaded into the hopper. The specialized force-feeder actively pushes the material into the extruder screw, ensuring a stable and continuous supply for high output.

The screw transports, compresses, and melts the plastic. A double-vented degassing zone removes any trapped moisture and volatiles, which is critical for producing high-quality, bubble-free pellets.

The molten plastic passes through a hydraulic screen changer to filter out impurities. It is then extruded through a die head and cut into uniform pellets by a high-speed water-ring or strand pelletizer.

Model Specifications

Select the ideal machine configuration for your specific material type and target output.

| Model | Screw Dia. | L/D Ratio | Motor | Output (kg/h) |

|---|---|---|---|---|

| SJ-100 | ⌀100mm | 24-36 | 45-55 kW | 150-250 |

| SJ-120 | ⌀120mm | 24-36 | 55-75 kW | 250-400 |

| SJ-150 | ⌀150mm | 24-36 | 90-132 kW | 400-600 |

| SJ-180 | ⌀180mm | 24-36 | 132-160 kW | 600-800 |

| SJ-200 | ⌀200mm | 24-36 | 185-280 kW | 800-1000 |

Tailor It To Your Needs

We offer flexibility based on your material and operational preferences.

Water-Ring Pelletizing

Ideal for high-output processing of materials like PP and HDPE. It cuts pellets at the die face for uniform, spherical shapes in a highly automated process.

Strand Pelletizing

A versatile method excellent for engineering plastics like ABS, PS, or glass-filled materials. Strands are cooled in a water bath before being cut into cylindrical pellets.

Explore the Machinery

Frequently Asked Questions

What pre-processing is required for hard plastics?

Yes. For best results, plastics must be pre-processed into clean, dry flakes of a uniform size (<12mm). This involves sorting, crushing, washing, and drying to remove all contaminants.

Can this machine handle mixed rigid plastics?

No. The line is optimized to process one type of plastic at a time (e.g., HDPE or PP). Mixing plastics with different melting points will result in poor-quality pellets, so proper sorting is essential.

How does the machine handle moisture in the flakes?

While input flakes should have under 1% moisture, our extruders feature a double-venting (degassing) system. This actively removes residual moisture and volatiles to prevent porous pellets and ensure a high-quality, smooth finish.

Does the line include a melt filter or screen changer?

Yes, a hydraulic screen changer is a standard and critical component. It filters contaminants from the molten plastic to produce clean pellets and protect the pelletizer blades.

Ready to Maximize the Value of Your Plastic Scrap?

Our team is ready to engineer the perfect granulating solution for your rigid plastic recycling needs. Let’s talk about how we can boost your quality, output, and profitability.