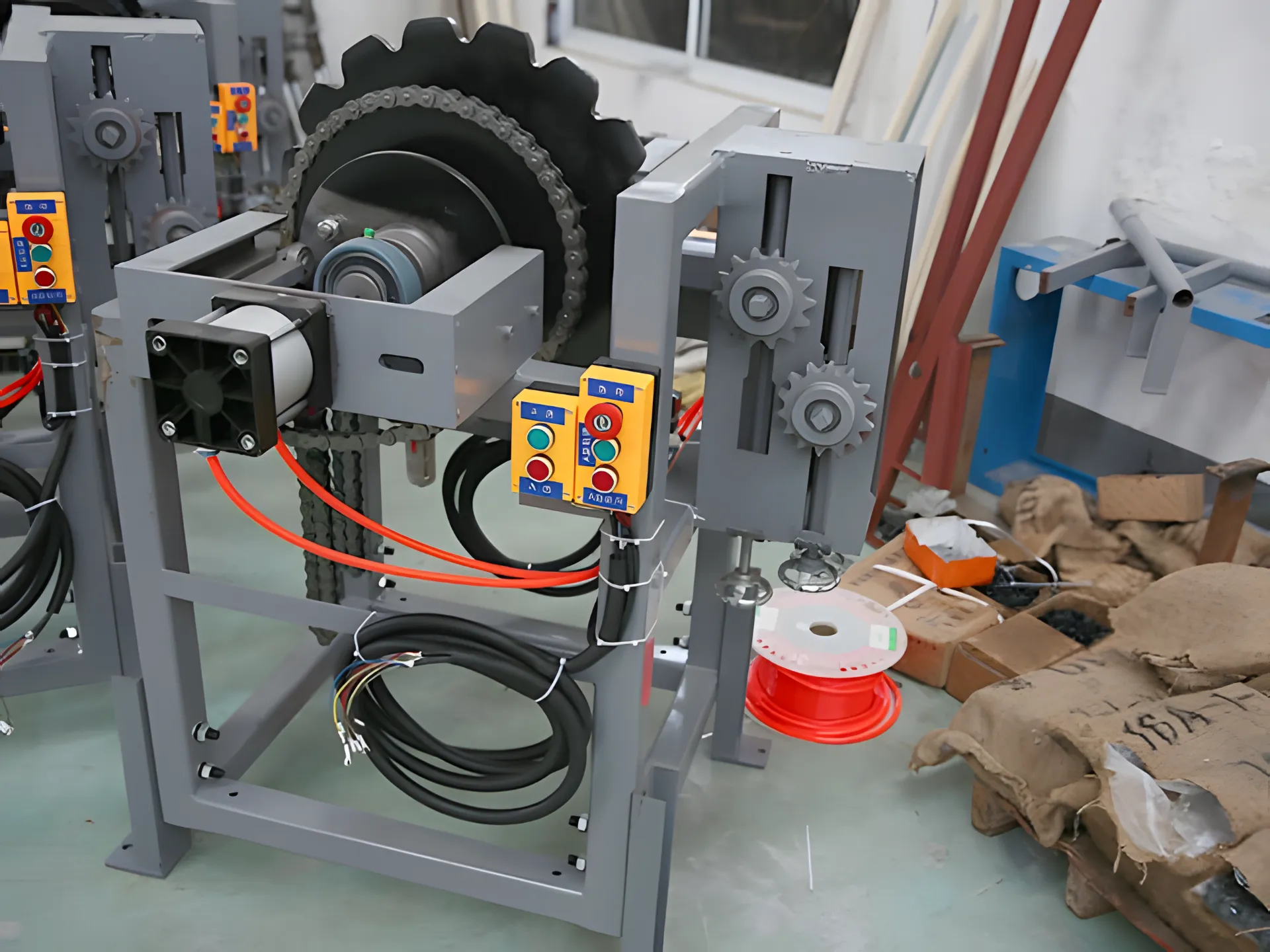

Power Take-Off Frame for PVC/Nitrile Glove Production Line

Engineered power take-off frame that syncs main drive to downstream glove line equipment with variable speed control, safety interlocks, and retrofit flexibility.

描述

Central Drive Interface for Seamless Line Integration

Customizable mechanical interface delivering stable, scalable power transmission from the main drive to downstream glove line equipment—ensuring integration, safety, and future growth.

Quick Highlights

- Modular power distribution

- Variable speed & torque control

- Safety interlocks & guards

- Future-ready expansion

Power Planning

Assess downstream torque and speed needs, aggregate load, and choose a drive with capacity plus headroom for scaling.

Transmission Options

Choose between helical gears for quiet smoothness, belts/pulleys for flexibility, or chains/sprockets for heavy torque—with proper tensioning and damping.

Safety & Serviceability

Include guards, emergency stop, interlocks, and accessible maintenance points—use quick-release or modular elements to reduce downtime.

Advanced Capabilities

- Variable Speed Drive (VSD): Fine-tune speed and torque for optimal matching to downstream processes and energy savings.

- Torque Limiter: Prevents overload damage by disengaging when preset thresholds are exceeded.

- Cooling Options: Optional thermal management for high-power applications to maintain consistent performance.

Customization

Adapt the PTO frame to your layout, glove type, desired throughput, and automation level—ensuring seamless integration and future scalability.

Collaboration

Work with engineering partners for torque modeling, alignment studies, system integration tests, and commissioning to guarantee real-world reliability.

FAQ

Q: Can the PTO frame be retrofitted to existing lines?

A: Yes. It can be adapted through layout assessment to match existing motors, gearboxes, and downstream equipment while preserving alignment.

Q: How is future capacity growth handled?

A: The design includes power margin and modular sections, enabling added downstream modules or increased throughput without full redesign.

Q: What safety features are standard?

A: Standard features include guarding, emergency stop, interlocks, and torque limiters to protect both equipment and operators.

Q: Is energy efficiency incorporated?

A: Yes. Variable Speed Drives allow matching operating speed to load, reducing wasteful overdrive and improving overall line efficiency.

Q: Do you provide integration support?

A: We offer engineering collaboration, on-site validation, and commissioning assistance to ensure proper alignment and performance.

Build the power backbone of your glove line with a PTO frame engineered for reliability and scale.