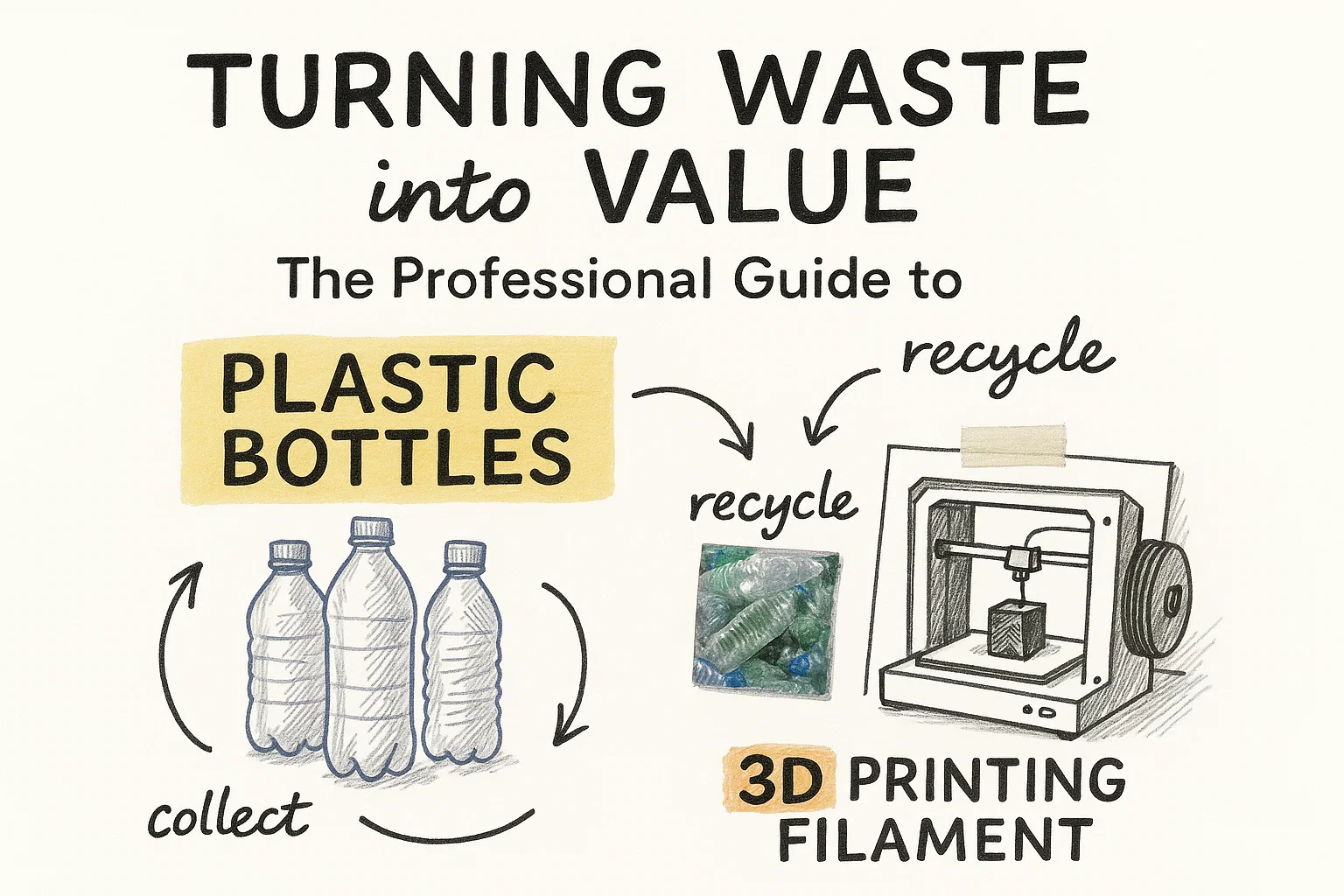

In the evolving landscape of sustainable manufacturing, the ability to close the loop on plastic waste is no longer just an environmental goal—it is a competitive advantage. For manufacturers, educational institutions, and industrial recyclers in the USA and Europe, the concept of transforming post-consumer PET bottles into high-quality 3D printing filament represents a frontier of cost efficiency and innovation.

At Rumtoo Machine, we understand that the transition from waste plastic to precision filament requires more than just enthusiasm; it demands robust engineering and reliable equipment. This guide explores the technical workflow, the business case for in-house extrusion, and how the right machinery can empower your operation.

The Shift Towards Circular Manufacturing

The global demand for 3D printing materials is skyrocketing, yet the reliance on virgin resins remains a costly bottleneck. Simultaneously, the European Union and North American regulatory bodies are tightening standards on plastic waste management, pushing industries toward “Circular Economy” models.

By recycling plastic bottles (specifically PET) into filament, businesses can:

- Reduce Material Costs: Recycled PET (rPET) is significantly cheaper than virgin filament spools.

- Enhance Brand Sustainability: Demonstrating a closed-loop process boosts E-E-A-T (Expertise, Authoritativeness, and Trustworthiness) in the eyes of eco-conscious clients.

- Gain Supply Chain Independence: Produce your own raw materials on-demand, mitigating supply chain disruptions.

From Bottle to Spool: Understanding the Workflow

Creating professional-grade filament from waste isn’t as simple as melting plastic. It requires a precise, multi-stage process to ensure the final product has the diameter consistency and mechanical properties needed for reliable printing.

1. Collection and Sorting

The process begins with gathering PET bottles. For industrial quality, materials must be sorted to remove non-PET contaminants (like PVC labels or Polypropylene caps), which have different melting points and can clog extruders.

2. Shredding and Granulation

The bottles must be reduced to uniform flakes. This is where a high-torque shredder is essential. Uneven chunks lead to inconsistent feeding in the extruder.

- Tip: For smaller operations, a dedicated single-shaft shredder ensures flakes are the optimal size (typically 4–8mm) for desktop extruders.

3. Washing and Drying (The Critical Step)

PET is hygroscopic—it absorbs moisture from the air. If extruded wet, the water boils inside the plastic, causing “hydrolysis.” This breaks the polymer chains, resulting in brittle, bubbly filament.

- Requirement: Flakes must be dried (often for 4+ hours) to a moisture content below 0.05% before extrusion.

4. Extrusion and Spooling

This is where the magic happens. The dried flakes are fed into an extruder where they are melted, pressurized, and pushed through a precision die. The molten plastic is then cooled in a water bath or air path and wound onto a spool.

Spotlight on Technology: The Rumtoo Advantage

Achieving a uniform filament diameter (standard 1.75mm or 2.85mm) is the biggest challenge in this process. A variance of just ±0.05mm can jam a 3D printer. This is why “DIY” setups often fail and why professional hardware is necessary.

At Rumtoo Machine, we bridge the gap between industrial-grade recycling lines and accessible desktop solutions. For labs, small manufacturers, and rapid prototyping hubs, we offer specialized equipment designed to handle these rigors.

The Desktop 3D Filament Extruder Maker

Our flagship solution for this application is the desktop 3d filament extruder maker. Unlike standard industrial behemoths, this compact unit is engineered for precision and ease of use in smaller workspaces without sacrificing output quality.

Key Features of the Rumtoo System:

- Precision Screw Design: Optimized specifically for thermoplastics like PET, PLA, and ABS to ensure a homogenous melt.

- PID Temperature Control: Maintains heat within ±1°C, preventing the thermal degradation that commonly ruins recycled PET.

- Integrated Spooling: Automated winding ensures neat spools that are ready for immediate printing.

Comparison: Industrial vs. Desktop Solutions

| Feature | Industrial Recycling Line | Rumtoo Desktop Extruder |

| Throughput | 100+ kg/hour | 1–5 kg/hour |

| Footprint | Warehouse scale | Workbench scale |

| Power Usage | High (3-Phase) | Low (Standard Outlet) |

| Target User | Municipal Recycling Plants | R&D Labs, SMEs, Universities |

| Flexibility | Low (Long changeover times) | High (Quick material swaps) |

Overcoming Technical Challenges with Rumtoo

As a professional in the industry, you likely have concerns about quality control. Here is how Rumtoo Machine addresses the common pain points of rPET filament production:

Challenge 1: Viscosity Variation

Recycled plastic often has varying “Melt Flow Indices” (MFI) depending on the source bottles.

- Solution: Our extruders feature adjustable speed and temperature zones, allowing operators to fine-tune the flow for different batches of recycled material, ensuring a stable filament output.

Challenge 2: Contamination

Even small dust particles can block a 0.4mm 3D printer nozzle.

- Solution: Rumtoo recommends and supplies melt filters that can be integrated into the extrusion workflow, catching microscopic debris before it forms into the filament.

Challenge 3: Ovality and Tolerance

Filament that is oval-shaped rather than round will cause under-extrusion in printers.

- Solution: Our cooling and pulling systems are synchronized. The consistent tension provided by the haul-off unit ensures the filament remains round and dimensionally accurate as it hardens.

Frequently Asked Questions (FAQ)

Q1: Can I recycle dirty plastic bottles directly into filament?

No. Contaminants like glue, sugar residues, and dirt will carbonize in the extruder, ruining the nozzle and the filament quality. Bottles must be thoroughly washed and dried before processing.

Q2: What is the difference between PET and PETG?

Standard water bottles are made of PET. PETG is a glycol-modified version often used in 3D printing because it is easier to print. However, recycled PET (rPET) is stronger and more heat-resistant than PETG, making it excellent for functional parts, provided you use a machine capable of handling its higher melting point—like the Rumtoo desktop 3d filament extruder maker.

Q3: How much money can I save by making my own filament?

High-quality commercial filament can cost $20–$50 per kg. Raw recycled pellets or flakes can cost pennies per kg (often free if sourcing your own waste). For users printing 10kg+ per month, the ROI on an extruder can be realized in less than a year.

Q4: Does Rumtoo Machine offer support for installation?

Yes. We pride ourselves on comprehensive after-sales support. We provide manuals, guidance on parameter settings for different plastics, and technical assistance to ensure your production line is running smoothly.

Ready to Close the Loop?

Transforming plastic waste into valuable production resources is a smart manufacturing move. Whether you are looking to reduce operational costs or meet aggressive sustainability targets, Rumtoo Machine has the expertise and the equipment to make it happen.

Don’t let valuable material go to waste. Equip your facility with high-performance extrusion technology today.

Contact Rumtoo Machine now for a quote or to discuss your specific recycling requirements with our engineering team. Let’s build a greener future, one layer at a time.