Introduction

The global plastic recycling industry faces a critical challenge: converting massive volumes of plastic waste into high-quality raw materials that manufacturers can reuse. At the center of this transformation process stands the plastic pelletizer—a sophisticated piece of machinery that converts processed plastic waste into uniform pellets ready for remanufacturing.

For recycling facility operators, equipment managers, and plastic processing professionals, understanding pelletizer functionality and selecting the right type of equipment directly impacts production efficiency, pellet quality, and profitability. This comprehensive guide examines the core functions of plastic pelletizers, explores the major types available, and provides practical guidance for equipment selection.

What Is a Plastic Pelletizer?

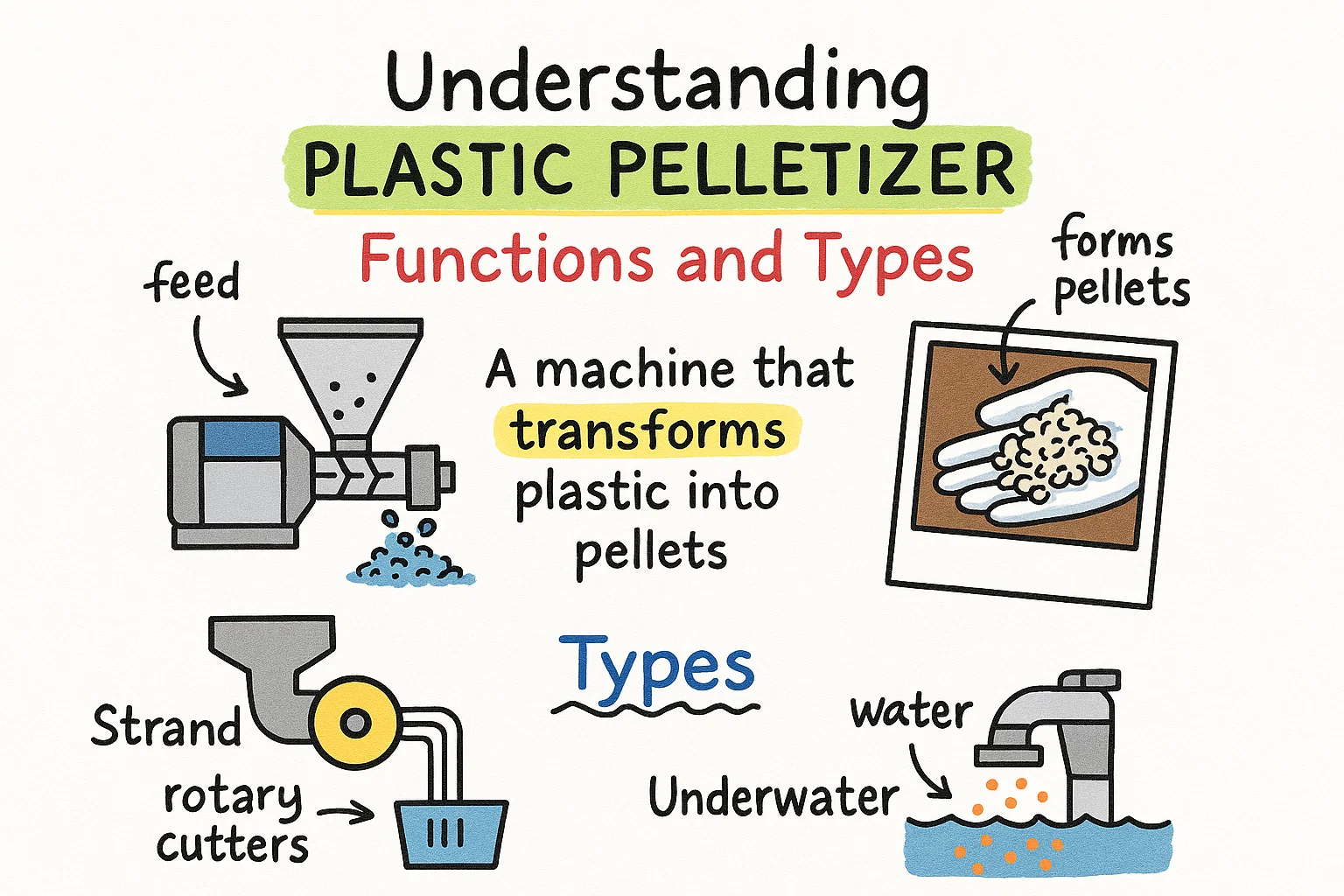

A plastic pelletizer is an industrial machine designed to convert plastic materials—whether recycled waste, post-industrial scrap, or virgin resin—into small, uniform granules called pellets. These pellets serve as standardized raw material for injection molding, blow molding, extrusion, and other plastic manufacturing processes.

The pelletizing process represents the final and most critical step in plastic recycling, determining the quality, consistency, and market value of the recycled material. A well-designed pelletizer produces pellets with consistent size, shape, density, and purity—characteristics that directly influence how easily the material can be reprocessed and what applications it’s suitable for.

Core Functions of Plastic Pelletizers

Material Melting and Homogenization

The primary function of any pelletizer begins with melting plastic feedstock to a precisely controlled temperature. The extruder barrel, equipped with heating elements and a rotating screw, converts solid plastic flakes or shreds into a homogeneous molten state. This process eliminates inconsistencies in the material, ensuring uniform properties throughout the final pellets.

Temperature control is critical during this phase. Different plastic polymers—such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS)—require specific melting temperatures. Advanced pelletizers feature multi-zone heating systems that allow precise temperature management throughout the extruder barrel.

Filtration and Purification

High-quality pellets demand thorough removal of contaminants. Pelletizers incorporate filtration systems that screen out foreign materials, unmelted particles, and degraded plastic before the molten material reaches the die head. Screen changers—whether manual, hydraulic, or continuous—enable operators to maintain filtration efficiency without stopping production.

This filtration function is especially crucial when processing post-consumer plastics, which often contain paper labels, adhesives, metal fragments, and other contaminants that survived earlier washing stages. Effective filtration protects downstream equipment and ensures pellets meet quality specifications for demanding applications.

Degassing and Moisture Removal

Trapped air, moisture, and volatile compounds compromise pellet quality, causing defects like bubbles, weak spots, and discoloration. Modern pelletizers incorporate degassing systems that create vacuum conditions within the extruder, allowing these unwanted elements to escape before the plastic is pelletized.

Degassing is particularly important for hygroscopic materials like PET and nylon, which readily absorb moisture from the atmosphere. Without proper degassing, moisture vaporizes during subsequent reprocessing, creating defects in finished products.

Pellet Formation and Cutting

Once the molten plastic is filtered and degassed, it’s forced through a die plate with multiple small holes. As the plastic strands emerge, they’re immediately cut into pellets by a rotating blade system. The cutting method varies by pelletizer type, but all aim to produce uniform pellets with consistent dimensions.

Pellet size and shape affect downstream processing. Smaller pellets melt faster but may cause feeding issues, while larger pellets ensure smooth material flow but require longer melting times. Professional pelletizers allow adjustment of pellet dimensions to match specific production requirements.

Cooling and Drying

Freshly cut pellets are hot and often wet, requiring cooling and drying before packaging. Water-cooled systems immediately chill pellets in a water bath, then use centrifugal dryers or air classification systems to remove surface moisture. Air-cooled systems rely on forced air to gradually cool pellets without water contact.

The cooling method influences pellet characteristics. Water cooling produces harder, more crystalline pellets with sharper edges, while air cooling yields slightly softer pellets with rounder profiles. Your choice depends on the specific plastic type and intended application.

Major Types of Plastic Pelletizers

Single-Stage Pelletizers

Single-stage pelletizers integrate all processing steps—feeding, melting, filtering, and pelletizing—into one continuous operation with a single extruder. Material enters the hopper, passes through the extruder where it’s melted and filtered, then immediately moves to the die head for cutting into pellets.

Advantages:

- Lower initial investment compared to multi-stage systems

- Reduced energy consumption due to single-pass processing

- Compact footprint suitable for facilities with limited space

- Simplified operation and maintenance requirements

- Efficient for clean, pre-sorted materials with minimal contamination

Optimal Applications:

- Post-industrial scrap with consistent quality

- Pre-washed plastic waste from controlled sources

- Operations prioritizing cost efficiency over maximum throughput

- Facilities processing single polymer types

Two-Stage Pelletizers

Two-stage systems separate the melting and pelletizing functions into two distinct extruders. The first extruder melts and filters the material, then feeds it to a second extruder that provides additional homogenization and precise temperature control before pelletizing.

Advantages:

- Superior filtration capabilities for heavily contaminated materials

- Enhanced degassing removes more moisture and volatiles

- Better output consistency regardless of feed material variations

- Higher throughput capacity for industrial-scale operations

- Improved pellet quality suitable for premium applications

Optimal Applications:

- Post-consumer plastics with variable contamination levels

- High-volume recycling facilities processing multiple tons per hour

- Applications requiring food-grade or near-virgin quality pellets

- Operations processing mixed plastic streams

Hot-Cut Pelletizers

Hot-cut systems feature rotating blades positioned directly at the die face, cutting pellets while the plastic is still molten. Water sprays immediately cool the pellets, which are then dried and sorted.

Advantages:

- Produces spherical pellets with minimal dust generation

- Excellent for heat-sensitive materials requiring quick cooling

- High production speeds suitable for large-scale operations

- Consistent pellet dimensions with tight tolerances

Considerations:

- Requires water treatment and recirculation systems

- Higher maintenance on cutting blades due to wear

- Not suitable for all polymer types, particularly those sensitive to rapid cooling

Strand Pelletizers

Strand pelletizers extrude plastic through a multi-hole die plate, creating continuous strands that pass through a water bath for cooling. Once solidified, the strands are fed into a rotating blade pelletizer that cuts them into uniform lengths.

Advantages:

- Versatile system handling a wide range of polymers

- Lower maintenance costs compared to hot-cut systems

- Better suited for materials requiring gradual cooling

- Easy adjustment of pellet size by changing cutting frequency

Considerations:

- Larger footprint due to strand cooling and pelletizing equipment

- Slightly less uniform pellet shape compared to hot-cut systems

- May produce more fines and dust requiring screening

Underwater Pelletizers

Underwater pelletizing systems cut pellets immediately at the die face while submerged in a water-filled cutting chamber. This method combines cutting and cooling in a single step, producing spherical pellets with excellent uniformity.

Advantages:

- Superior pellet quality with highly consistent dimensions

- Minimal dust and fines generation

- Efficient cooling even for high-temperature polymers

- Reduced noise levels during operation

Considerations:

- Higher capital investment than strand pelletizing systems

- More complex maintenance requirements

- Requires sophisticated water treatment and temperature control

Air-Cooled Pelletizers

Air-cooled systems eliminate water from the cooling process entirely, using forced air to cool pellets after cutting. These systems are particularly valuable when processing materials that degrade or absorb moisture during water contact.

Advantages:

- No water treatment or disposal requirements

- Suitable for moisture-sensitive polymers

- Lower operating costs in water-scarce regions

- Eliminates concerns about water contamination

Considerations:

- Slower cooling rates limit throughput

- Larger cooling equipment footprint

- Less uniform pellet characteristics compared to water-cooled systems

Selecting the Right Pelletizer for Your Operation

Material Characteristics

Your feedstock determines which pelletizer type will perform optimally. Clean post-industrial scrap works efficiently with single-stage systems, while contaminated post-consumer waste demands the advanced capabilities of two-stage equipment. Consider polymer type, contamination level, moisture content, and whether you process single or mixed plastic streams.

Production Volume Requirements

Match pelletizer capacity to your actual throughput needs, with consideration for future expansion. Small operations processing 200-500 kg/hour typically succeed with single-stage strand pelletizers. Medium facilities handling 500-1,500 kg/hour benefit from two-stage systems. Large industrial operations exceeding 2,000 kg/hour require high-capacity two-stage equipment with advanced automation.

Quality Standards

Define your target pellet quality based on end-market requirements. Commodity applications accept wider quality tolerances achievable with basic single-stage systems. Premium markets demanding consistency comparable to virgin resin require sophisticated two-stage underwater pelletizers with advanced process controls.

Budget Considerations

Balance capital investment against long-term operational costs and revenue potential. While two-stage systems cost more initially, they often deliver superior economics through higher pellet quality, increased selling prices, and greater processing flexibility. Calculate total cost of ownership including energy consumption, maintenance, and expected pellet pricing.

Technical Support and Service

Equipment reliability directly impacts your operation’s profitability. Evaluate manufacturers based on engineering expertise, customization capabilities, installation support, operator training programs, spare parts availability, and responsive technical service. A reliable equipment partner becomes invaluable when addressing production challenges or optimizing performance.

Critical Pelletizer Components and Features

Extruder Screw Design

The extruder screw configuration significantly influences processing efficiency. General-purpose screws handle a variety of materials adequately, while specialized barrier screws, mixing screws, or vented screws optimize performance for specific polymers or contamination levels.

Screen Changer Systems

Screen changers enable continuous production while maintaining filtration effectiveness. Manual systems suit low-contamination materials, hydraulic sliding plate changers provide semi-automated operation, and continuous belt filters eliminate production interruptions entirely for heavily contaminated feedstock.

Temperature Control Systems

Multi-zone heating and cooling systems with precise PID controllers ensure optimal processing temperatures throughout the extruder barrel and die head. Advanced systems feature automatic temperature adjustment based on material characteristics and production conditions.

Automation and Monitoring

Modern pelletizers increasingly incorporate automation features that reduce labor requirements and improve consistency. Look for systems offering automated feeding, screen pressure monitoring, temperature logging, production rate tracking, and remote diagnostics.

Industry Trends Shaping Pelletizer Technology

Demand for Food-Grade Recycled Plastics

Regulatory changes and corporate sustainability commitments drive growing demand for food-contact recycled plastics. This trend favors advanced two-stage pelletizers with superior purification and quality control capabilities that meet stringent food safety standards.

Energy Efficiency Requirements

Rising energy costs and environmental concerns push manufacturers toward more efficient pelletizer designs. Innovations include improved insulation, optimized screw profiles, variable frequency drives, and waste heat recovery systems that reduce energy consumption per ton of processed plastic.

Automation and Industry 4.0 Integration

Pelletizer systems increasingly feature connectivity enabling real-time monitoring, predictive maintenance, and integration with facility management systems. These capabilities improve operational efficiency, reduce downtime, and facilitate quality documentation for certified recycled content programs.

Processing Challenging Materials

As recyclers tackle more complex waste streams—including multi-layer films, composite materials, and chemically contaminated plastics—pelletizer technology evolves to handle these challenging feedstocks. Advanced systems incorporate enhanced filtration, improved degassing, and specialized screw designs for difficult applications.

Maintenance and Operational Best Practices

Regular Maintenance Schedule

Implement preventive maintenance protocols covering screw and barrel inspection, screen changer servicing, cutting blade sharpening, gearbox lubrication, and heating element testing. Consistent maintenance extends equipment life and prevents costly unplanned downtime.

Operator Training

Well-trained operators maximize pelletizer performance while minimizing defects and equipment damage. Comprehensive training should cover startup and shutdown procedures, temperature management, troubleshooting common issues, and safety protocols.

Quality Monitoring

Establish systematic quality control procedures including regular pellet sampling, dimensional measurement, contamination inspection, and melt flow rate testing. Consistent monitoring enables rapid identification and correction of production issues.

Process Optimization

Continuously refine processing parameters based on material characteristics and market feedback. Document optimal settings for different material types, and adjust temperature profiles, screw speed, and cooling conditions to maximize efficiency and quality.

Conclusion

Understanding plastic pelletizer functions and types empowers recycling professionals to make informed equipment decisions that optimize their operations. Whether processing clean industrial scrap with a cost-effective single-stage system or handling complex post-consumer waste with a sophisticated two-stage underwater pelletizer, selecting the right equipment determines your success in the competitive recycling market.

The plastic pelletizer represents a significant capital investment that will influence your facility’s productivity, product quality, and profitability for years to come. Consider your specific material characteristics, production volume requirements, quality standards, and long-term business objectives when evaluating pelletizer options.

At Rumtoo, we engineer advanced plastic pelletizing solutions tailored to your unique recycling challenges. Our equipment combines proven reliability with cutting-edge technology, backed by comprehensive technical support to ensure optimal performance from day one.

Ready to enhance your plastic recycling operation? Contact our engineering team today for expert guidance on selecting the ideal pelletizer for your facility. Request a detailed equipment proposal and discover how Rumtoo pelletizing technology can transform your recycling efficiency and product quality.