Plastic Recycling Machines & Washing Lines

Industrial‑grade equipment and turnkey lines to transform PET, HDPE, PP and PE film into high‑quality flakes and pellets. Designed for uptime, energy efficiency and consistent output.

Explore solutions across the full process: Soft Plastic Washing Lines, Hard Plastic Washing Lines, Plastic Shredders, Crushers & Granulators, and Plastic Pelletizing Lines.

Why Choose Rumtoo Machinery

Expert Consultation

Our team provides expert guidance to help you select the perfect machinery for your specific needs and materials.

Quality Assurance

Every machine is built with robust components and undergoes rigorous testing to ensure durability and performance.

Customized Solutions

We design and configure complete recycling lines tailored to your operational scale and output requirements.

Global Support

We offer comprehensive after-sales service and technical support to clients across the globe, ensuring smooth operation.

Core Recycling Systems

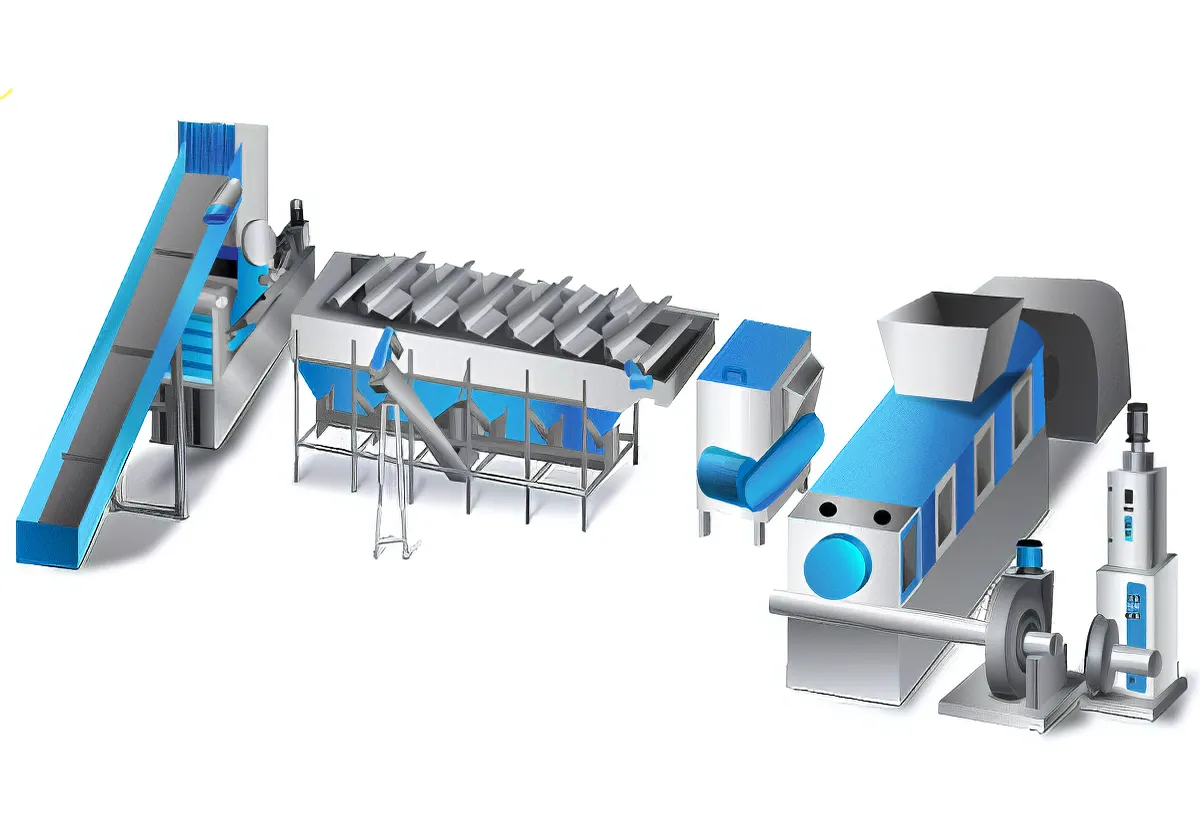

Soft Plastic Washing Lines

Efficiently wash, separate, and dry soft plastics like LDPE/LLDPE film and PP woven bags for high-quality pelletizing.

Soft Plastic Washing Lines

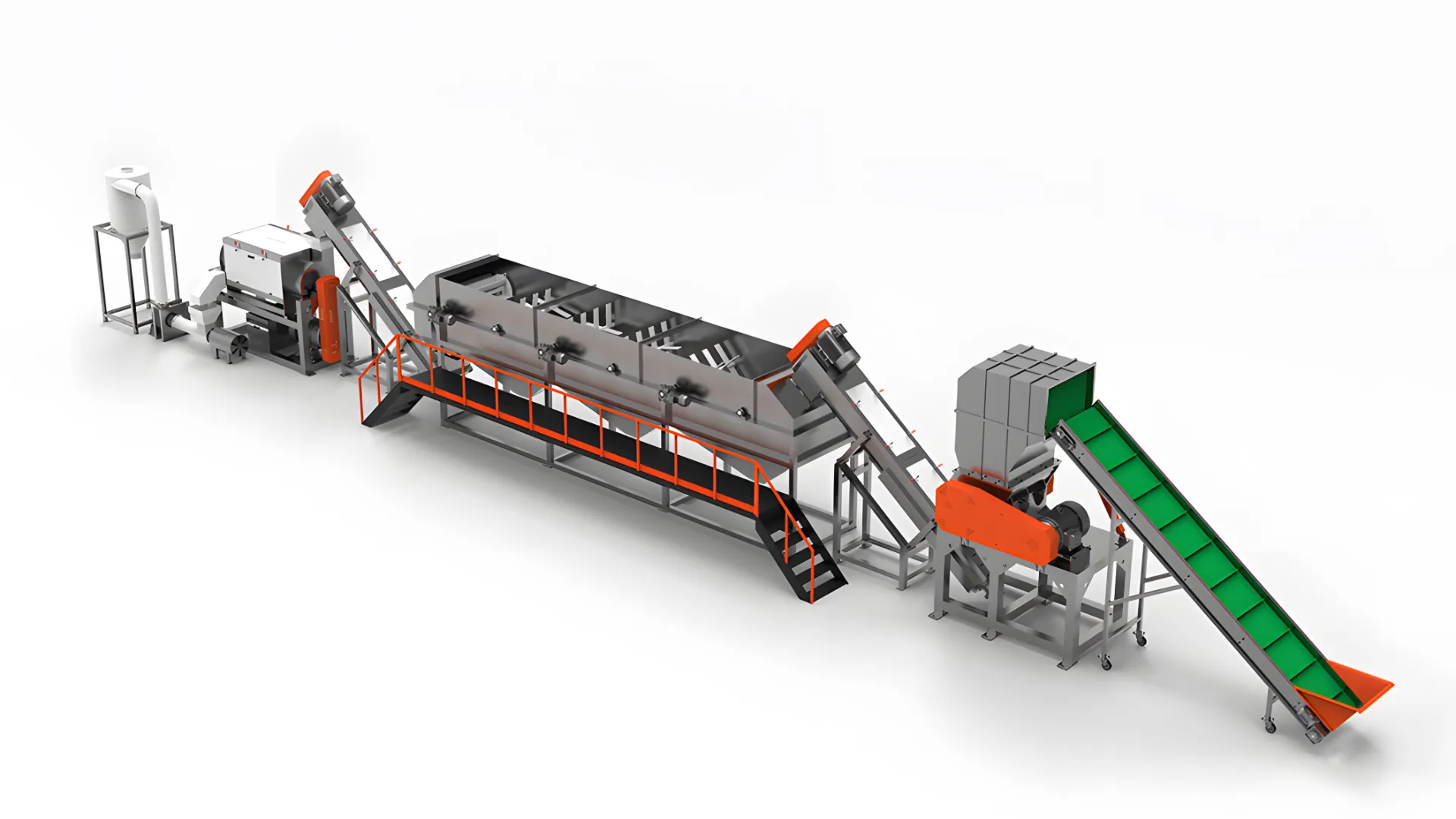

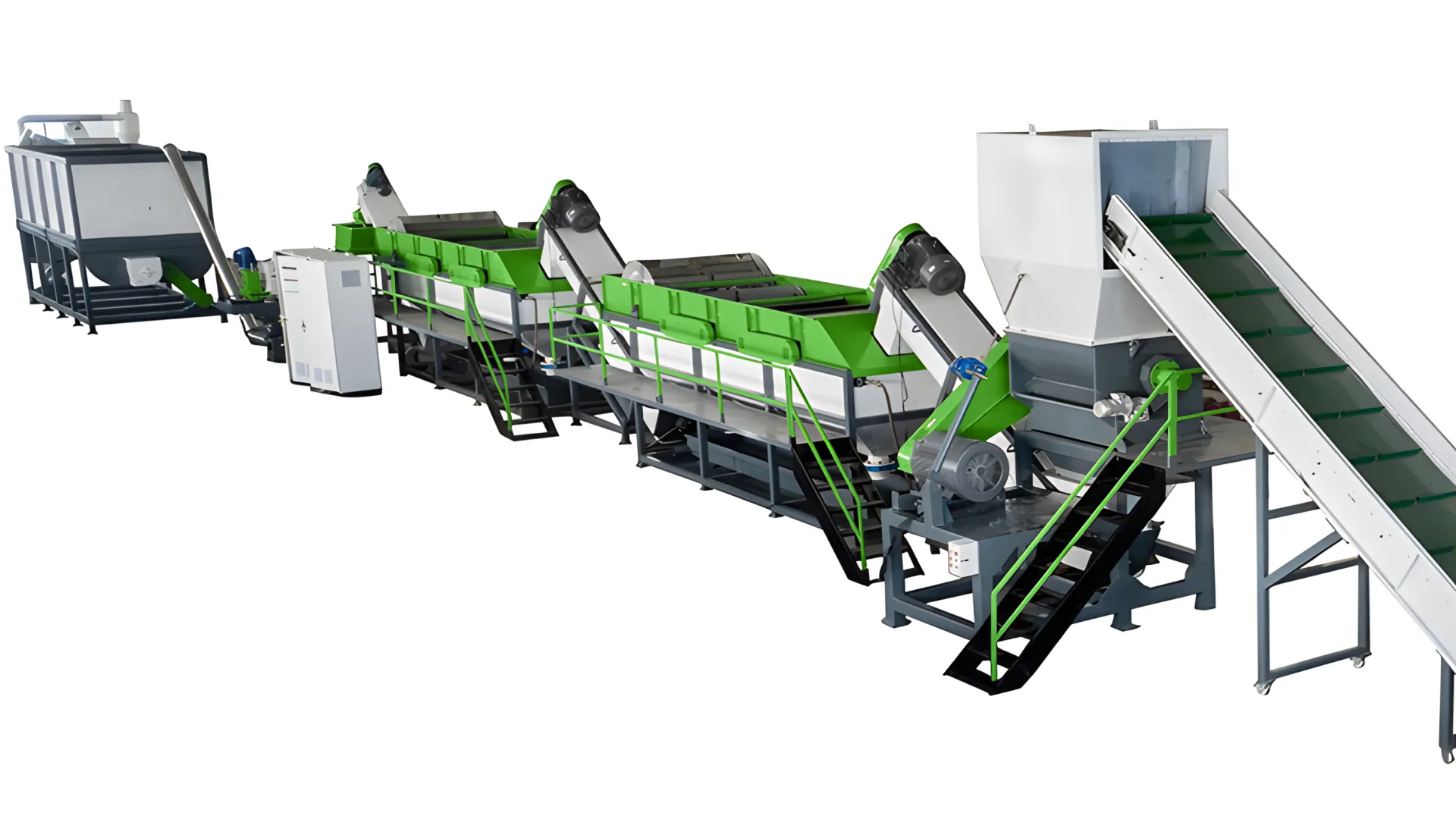

Hard Plastic Washing Lines

Complete systems for processing rigid plastics such as HDPE bottles, PP containers, and ABS/PS lumps from post-consumer or industrial waste.

Hard Plastic Washing Lines

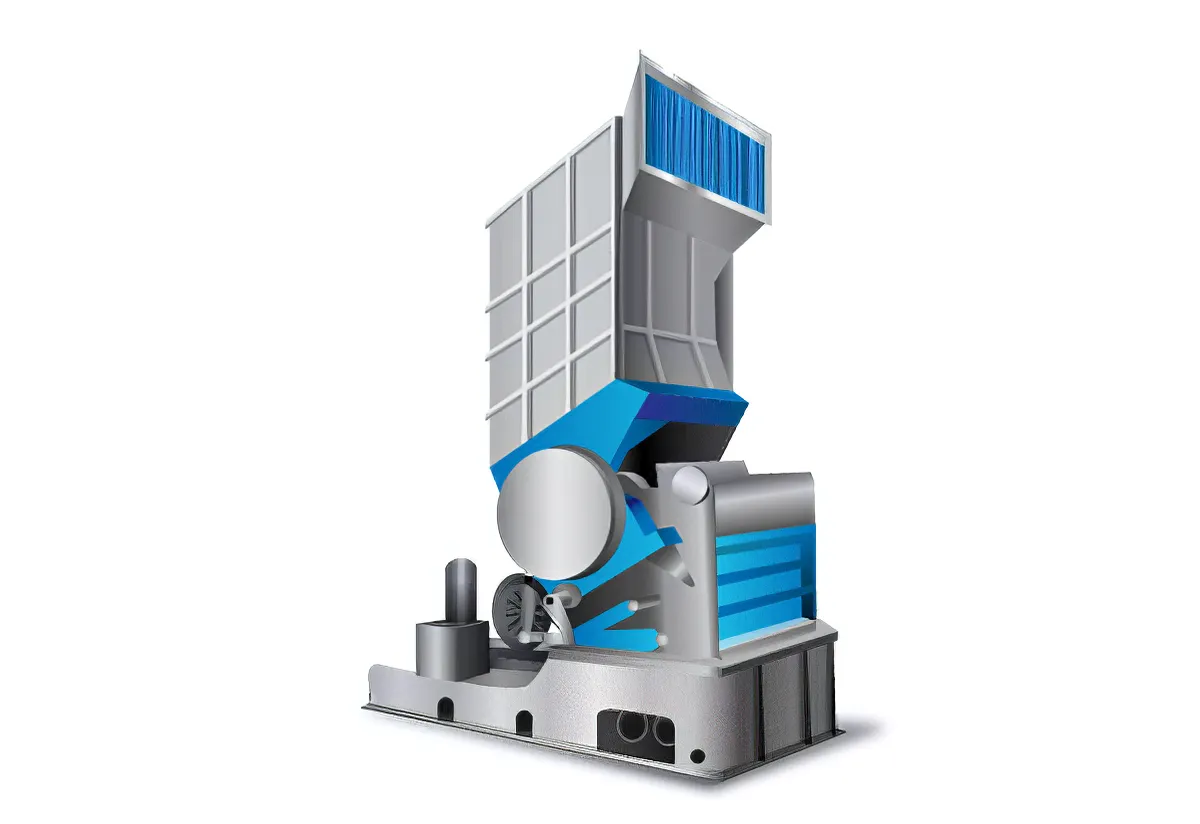

Plastic Shredders

Heavy-duty single and double-shaft shredders designed for initial size reduction of bulky materials, purgings, and plastic waste.

Plastic Shredders

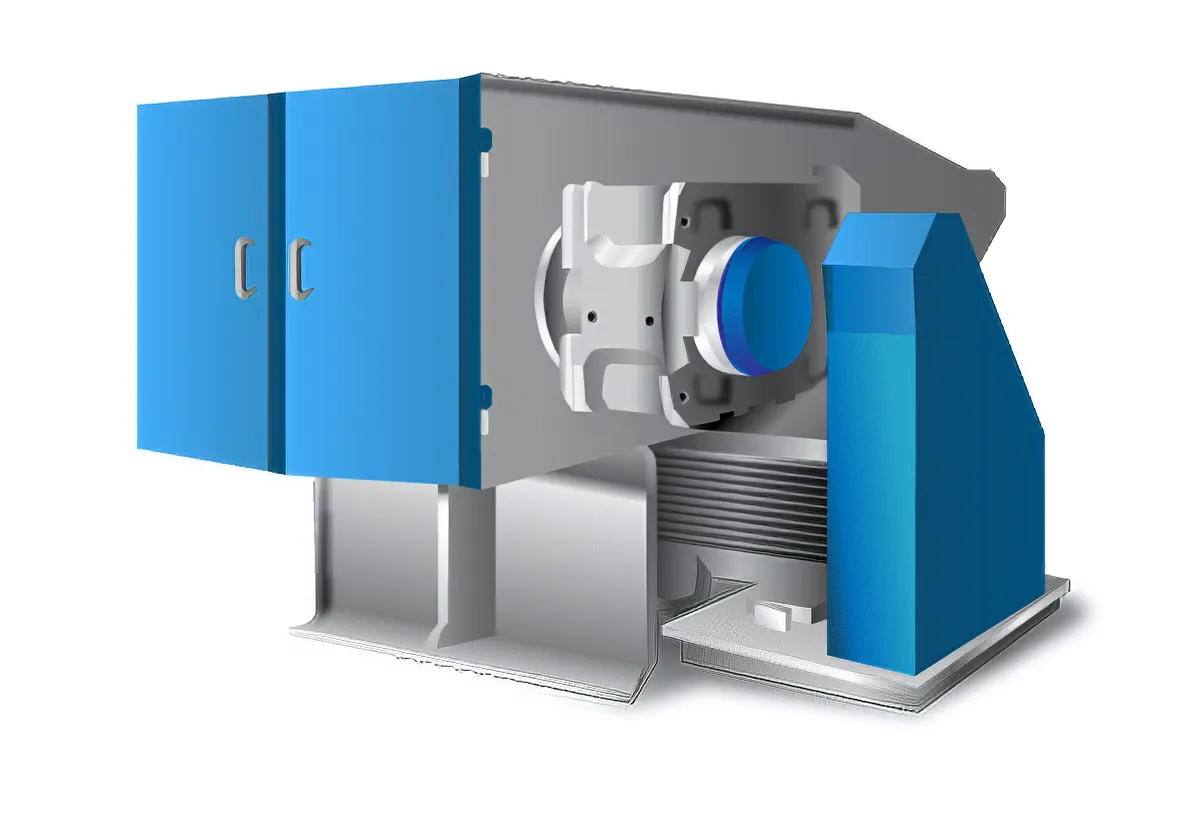

Crushers / Granulators

High-speed granulators for secondary size reduction, creating uniform regrind suitable for washing or direct reprocessing.

Crushers & Granulators

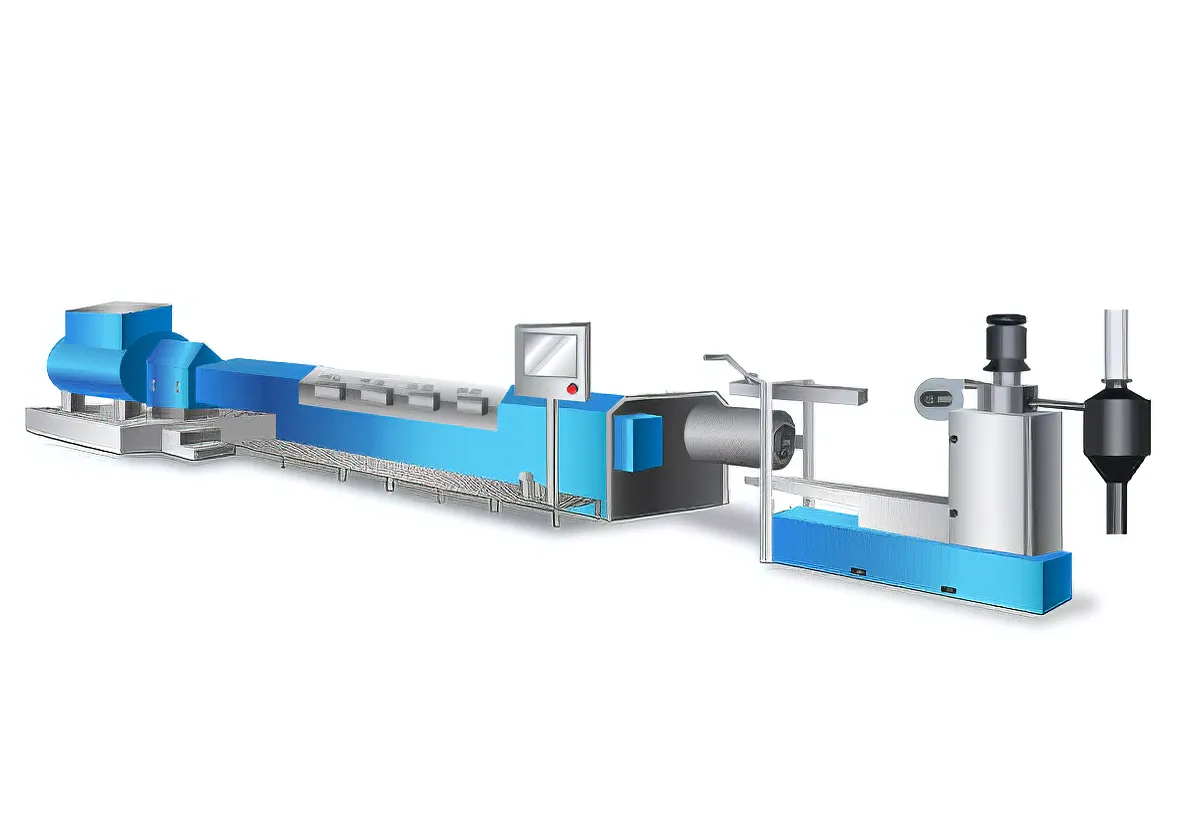

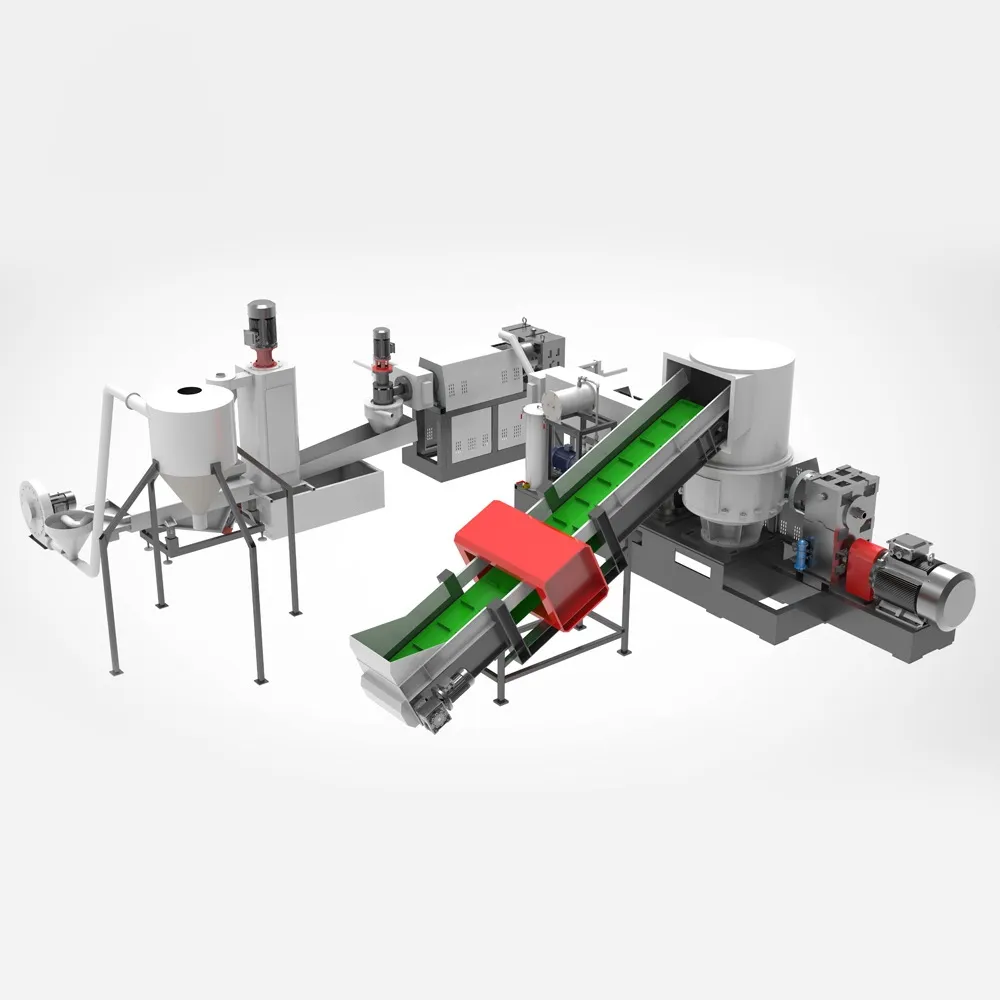

Pelletizing Lines

Advanced extrusion and pelletizing systems to convert cleaned plastic flakes into high-quality, reusable pellets.

Plastic Pelletizing Lines

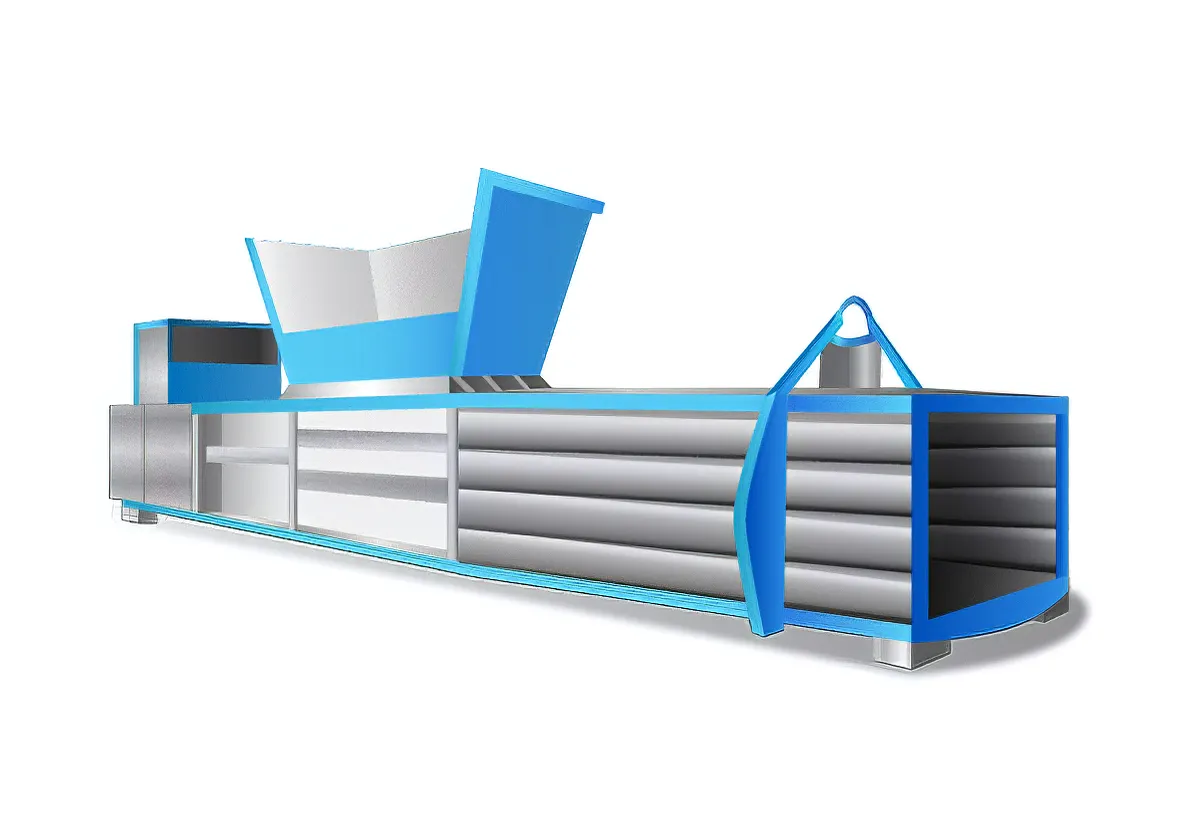

Baler Machines

Hydraulic balers for compacting loose plastic waste into dense, manageable bales for efficient storage and transportation.

Baler MachinesAuxiliary & Separation Systems

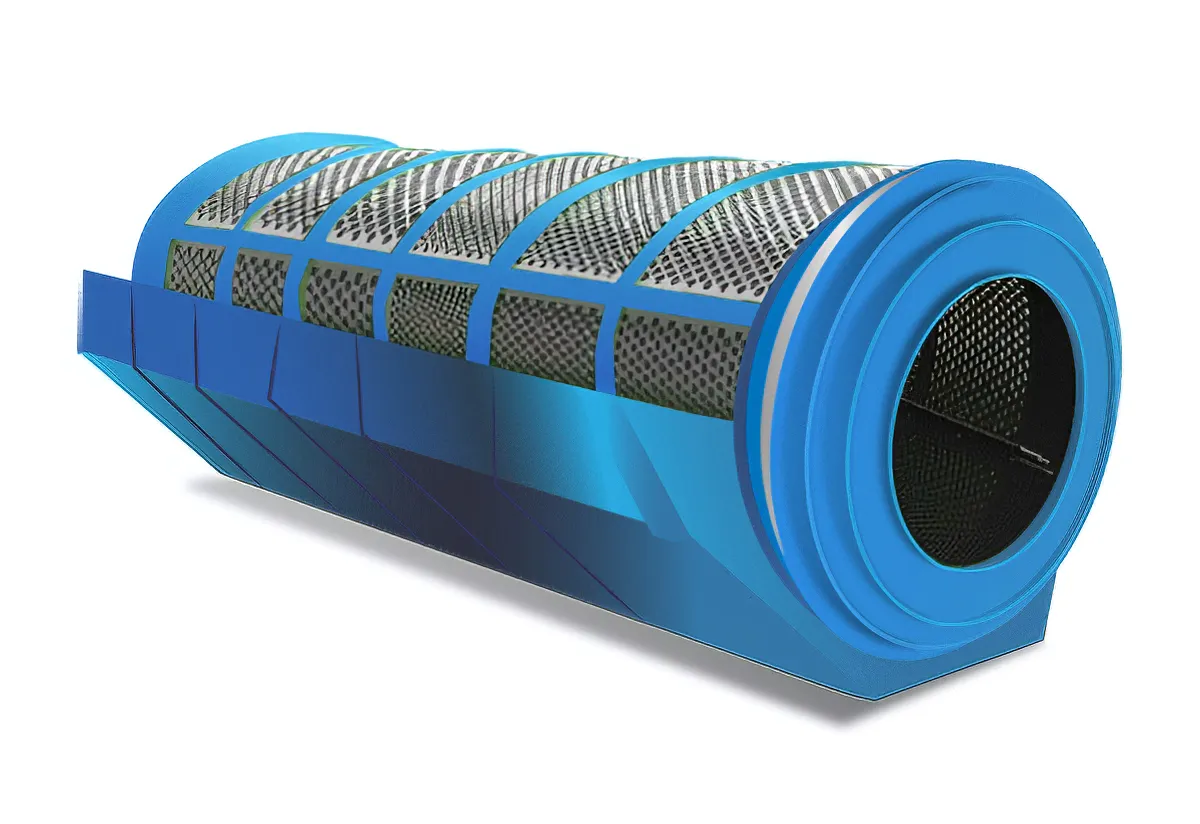

Sink-Float Separation Tanks

Utilizes water density to effectively separate different types of plastics, such as PET from polyolefins (PP/PE).

Sink-Float Separation Tanks

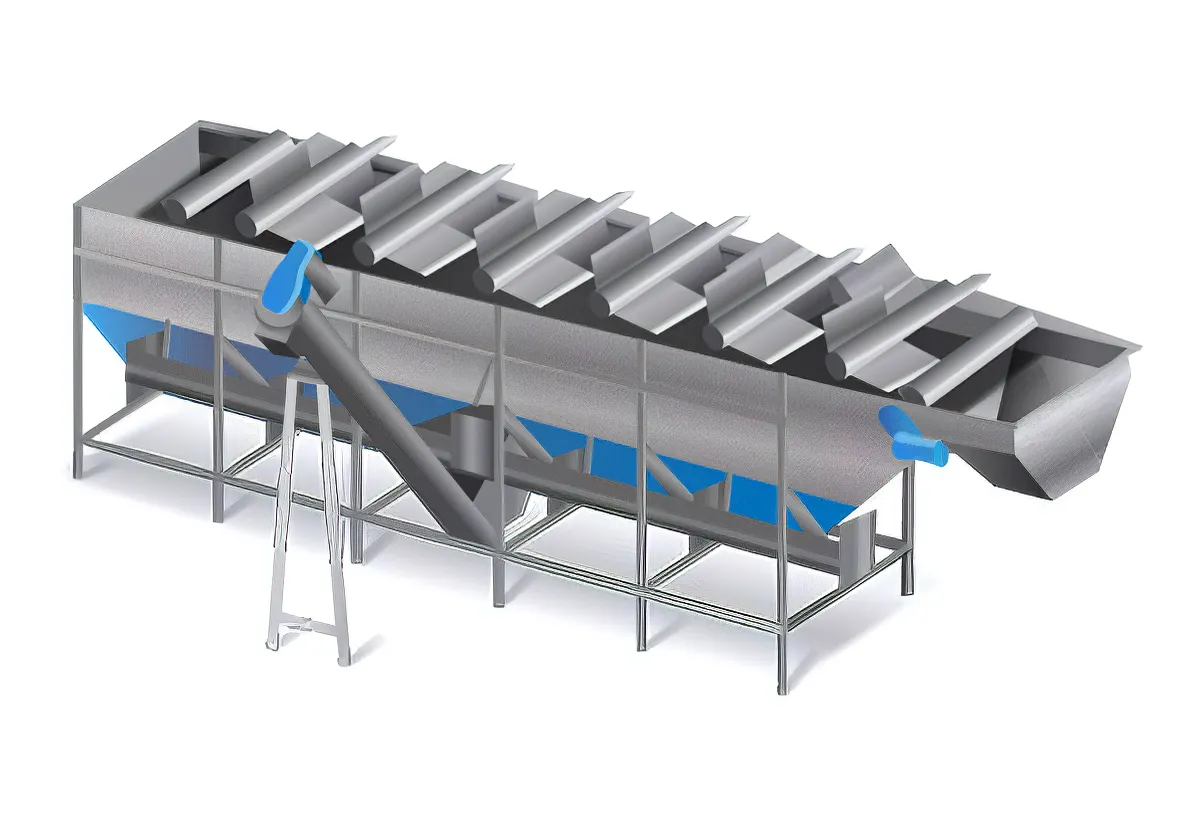

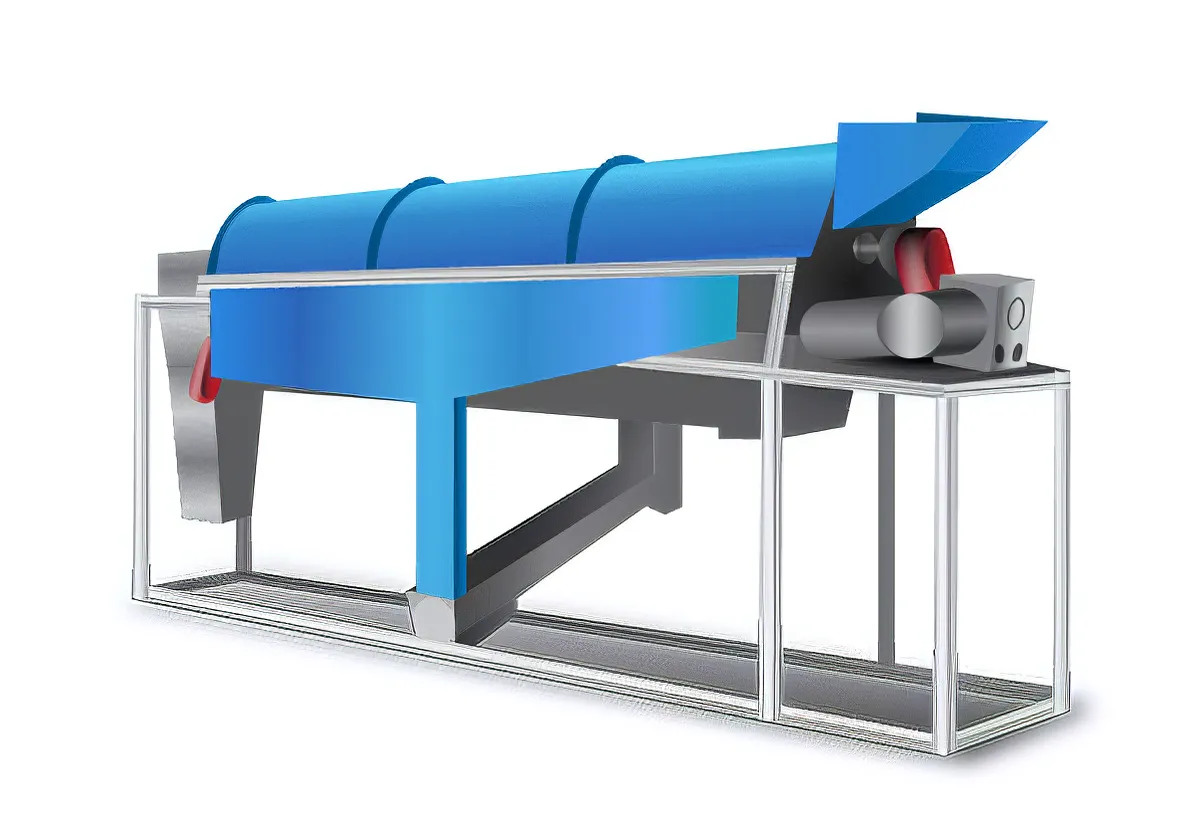

Trommels

Rotary screen separators for removing small contaminants like dirt, sand, and glass from the material stream before washing.

Trommels

Drying Systems

Includes centrifugal and thermal dryers to efficiently remove moisture from plastic flakes, ensuring low humidity for extrusion.

Plastic Drying Systems

Debalers

Breaks apart highly compressed bales of plastic bottles or film, preparing the material for the sorting and recycling process.

Debalers

Label Removers

Mechanically separates paper and plastic labels from PET bottles with high efficiency, reducing contamination in the final product.

Label Removers

Storage & Mixing Silos

Customizable storage and buffer solutions for raw materials, regrind, and finished pellets within the production line.

Storage & Mixing SilosA Wide Range of Processable Materials

PET Bottles

HDPE Barrels & Containers

LDPE / LLDPE Films

PP Woven Bags & Tapes

ABS / PS / PC Lumps

Equipment In Action

Frequently Asked Questions

What materials can your machines process? +

Our systems handle a wide range of plastics including PET bottles, HDPE barrels and containers, LDPE/LLDPE films, PP woven bags and tapes, and rigid plastics such as ABS/PS/PC lumps. Lines are configured based on your material mix and contamination level.

What capacity ranges are available? +

We design solutions from pilot to full‑scale production. Typical throughputs range from a few hundred to several thousand kilograms per hour depending on materials, contamination and the selected process modules.

What final moisture can be achieved after drying? +

With the appropriate combination of centrifugal and thermal drying, low residual moisture suitable for downstream extrusion and pelletizing is achievable. Actual performance depends on input material and line configuration.

Do you provide installation and after‑sales support? +

Yes. We offer line layout guidance, commissioning support, operator training and long‑term technical service, with spare parts and remote assistance to minimize downtime.

Can you customize a solution for our plant? +

Absolutely. We tailor equipment selection and line layout to your materials, space constraints, utilities and target output quality. Speak with our team to get a practical, cost‑effective configuration.

Ready to Optimize Your Recycling Operations?

Contact our experts today for a personalized consultation and a competitive quote on equipment tailored to your needs.

Request a QuoteSign up for our weekly campaign to receive offers on machines.