High-Torque Dual-Shaft Shear Shredders

Engineered by RUMTOO for high-volume processing, our dual-shaft shredders excel at reducing a wide array of challenging materials. From industrial plastics and scrap metals to end-of-life tyres, discover robust performance and precision with advanced shear cutting technology.

Tackling the Toughest Recycling Challenges

From bulky industrial plastics to scrap metal and end-of-life tyres, RUMTOO’s dual-shaft shredder transforms your most challenging materials into manageable, recyclable assets.

Common Problems

- Difficulty processing tough, dense, or bulky materials like metal drums and tyres.

- Frequent machine jamming and costly operational downtime.

- Inconsistent particle size and poor shred quality.

RUMTOO’s Dual-Shaft Solution

- High-torque shear cutting technology processes the toughest materials with ease.

- Intelligent PLC control with auto-reverse prevents jams and protects equipment.

- Customizable blade configuration ensures consistent output size and quality.

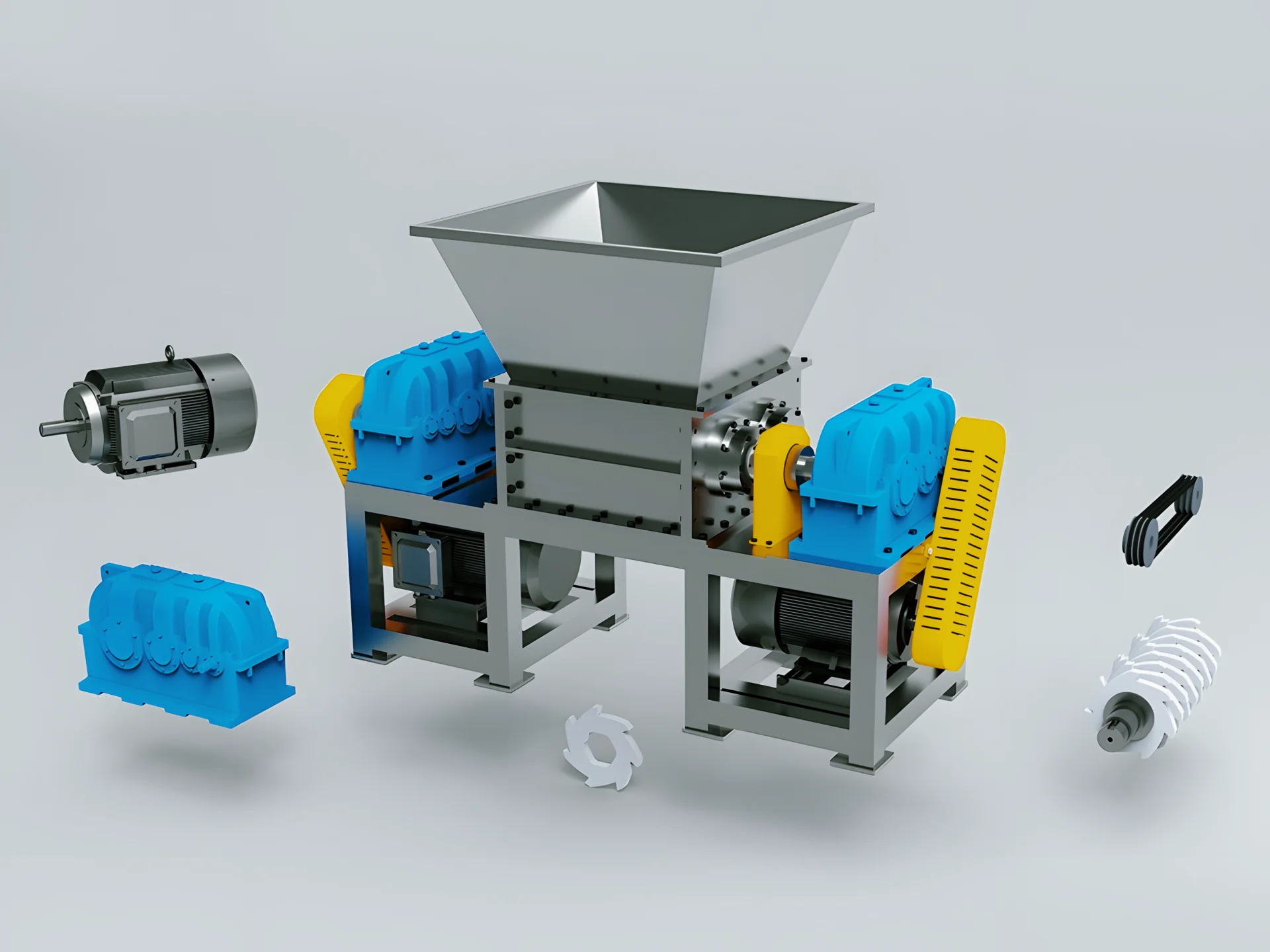

Core Engineering Features

Engineered by RUMTOO for maximum performance, reliability, and total cost of ownership.

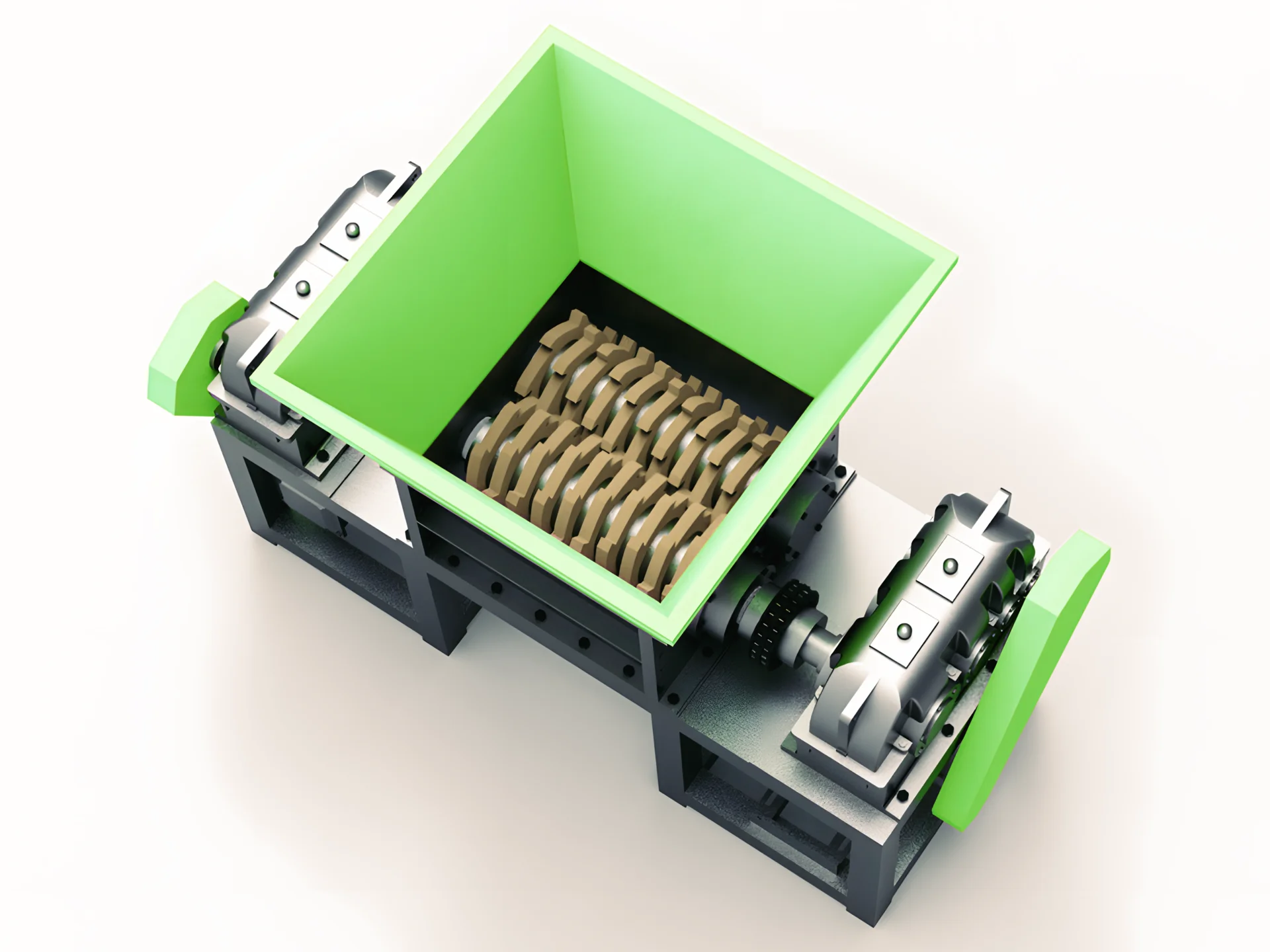

How It Works: A Simple 3-Step Process

RUMTOO’s streamlined dual-shaft workflow ensures maximum efficiency and throughput.

Machine Gallery

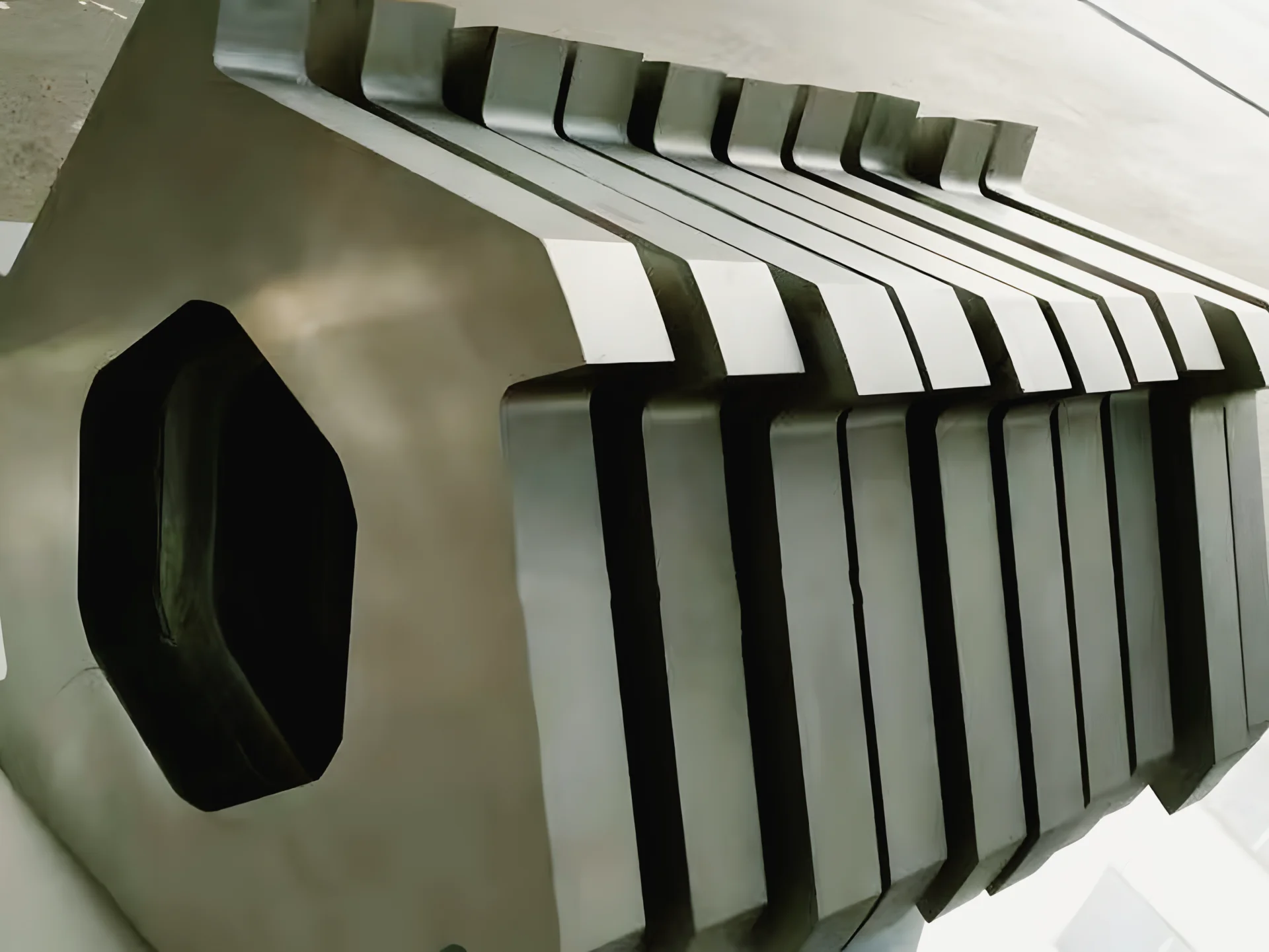

Explore RUMTOO’s dual-shaft shredder engineering excellence.

Technical Specifications

Choose the perfect RUMTOO model for your throughput requirements.

| Model | Shaft Diameter (mm) | Rotor Knives (pcs) | Throughput (kg/h) | Motor Power (kW) | Dimensions (L×W×H mm) |

|---|---|---|---|---|---|

| RTM-600-DCR | 320×45 | 12 | ~800 | 18.5×2 | 2960×880×2300 |

| RTM-800-DCR | 320×45 | 16 | ~1000 | 22×2 | 3160×920×2400 |

| RTM-1000-DCR | 400×50 | 20 | ~2000 | 45×2 | 3360×980×2500 |

| RTM-1200-DCR | 400×50 | 24 | ~3000 | 55×2 | 3760×980×2550 |

| RTM-1600-DCR | 500×65 | 24 | ~5000 | 75×2 | 4160×1080×2600 |

| RTM-2000-DCR | 600×77 | 28 | ~8000 | 90×2 | 4600×1220×2800 |

Materials We Process

RUMTOO’s dual-shaft shredders handle a diverse range of challenging materials for volume reduction and recycling preparation.

Scrap Metal & Drums

Shred metal drums, IBC containers, and industrial scrap with ease.

End-of-Life Tyres

Process waste tyres into uniform chips for recycling and fuel applications.

Waste Wood & Pallets

Reduce bulky wood waste, pallets, and construction timber efficiently.

Frequently Asked Questions

Get answers to common questions about RUMTOO’s Dual-Shaft Shredder.

What materials can the dual-shaft shredder process?

RUMTOO’s dual-shaft shredder can process a wide range of materials including industrial plastics, scrap metal drums and IBC containers, end-of-life tyres, waste wood and pallets, construction timber, and other challenging materials requiring volume reduction for recycling.

How does the dual-shaft design improve performance?

The dual-shaft design features counter-rotating shafts with interlocking blades that create a high-torque shearing action. This powerful cutting mechanism efficiently processes tough materials while the intelligent load-sensing system prevents jamming and protects the equipment.

What maintenance is required for this shredder?

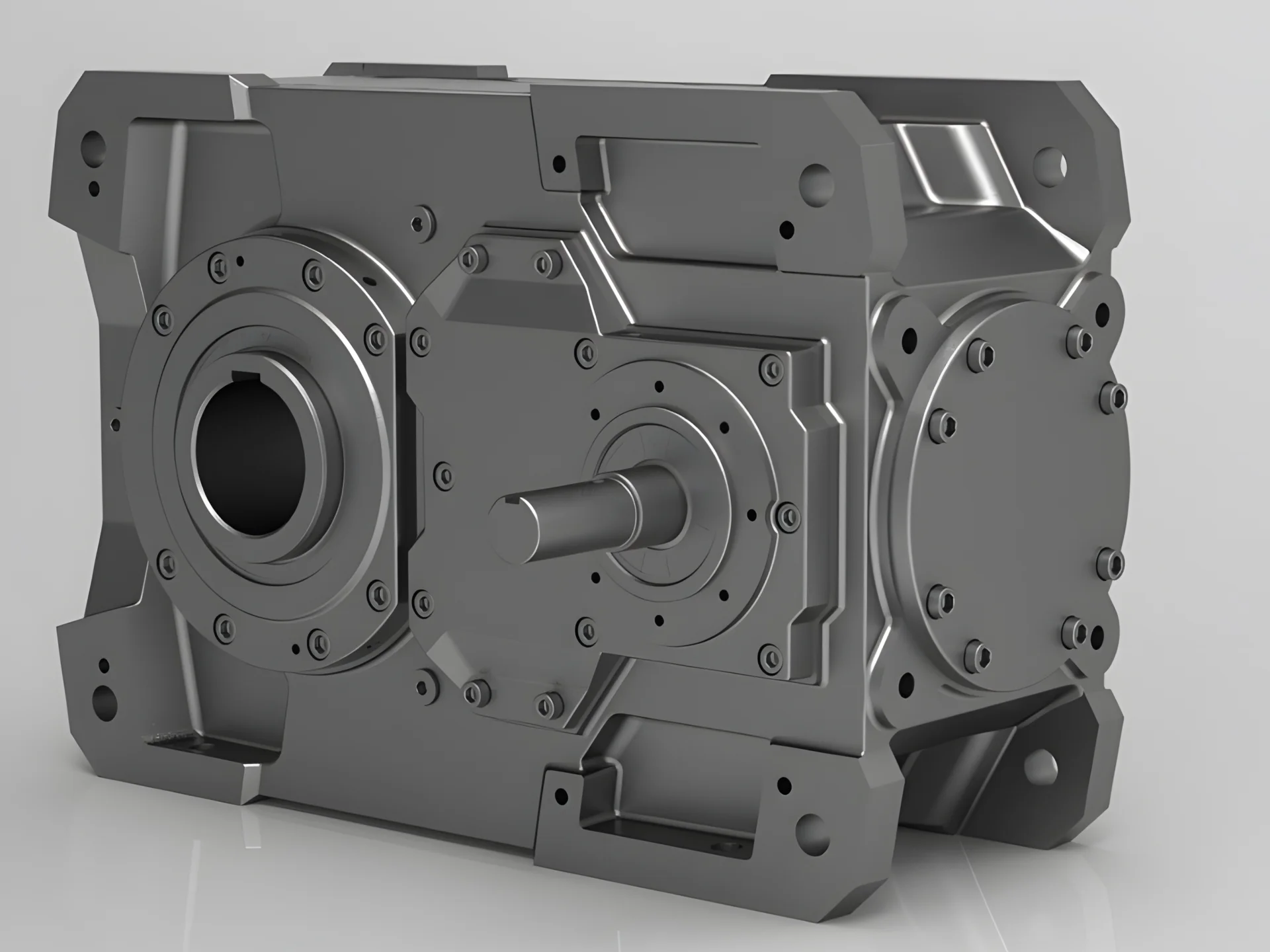

RUMTOO’s dual-shaft shredder features an advanced coupling system that simplifies maintenance. Blades are customizable and can be replaced as needed. The robust drivetrain design with planetary gear reducers ensures long service life with minimal maintenance requirements. Regular inspection of belts, pulleys, and blade condition is recommended.

Can the blade configuration be customized?

Yes, blade material, thickness, and hook design can be tailored to your specific application. This customization ensures optimal throughput and consistent shred size for your particular material type and processing requirements.

What control systems are available?

RUMTOO’s dual-shaft shredder is equipped with an intuitive Siemens PLC control system featuring automatic load-sensing and anti-jamming reversal. This ensures reliable, safe, and efficient autonomous operation with minimal manual intervention.

What throughput capacity should I choose?

RUMTOO offers models ranging from 800 kg/h (RTM-600-DCR) to 8000 kg/h (RTM-2000-DCR). The right capacity depends on your material type, volume, and desired output. Our specialists can help you select the optimal model for your specific requirements.

Does RUMTOO provide installation and training?

Yes, RUMTOO offers comprehensive installation services and operator training to ensure your team can operate the dual-shaft shredder safely and efficiently. Technical support is also available to assist with any questions or issues.

What makes RUMTOO’s shredder different from competitors?

RUMTOO’s dual-shaft shredder combines high-torque shear cutting technology, robust planetary gear reducers, advanced coupling systems for easy maintenance, Siemens PLC control, and fully customizable blade configurations. This results in superior performance, lower maintenance costs, and reliable operation for the toughest materials.

Ready to Enhance Your Recycling Operations?

Contact RUMTOO specialists today to discuss your material challenges. We will configure the perfect dual-shaft shredder solution to meet your specific throughput and output requirements.