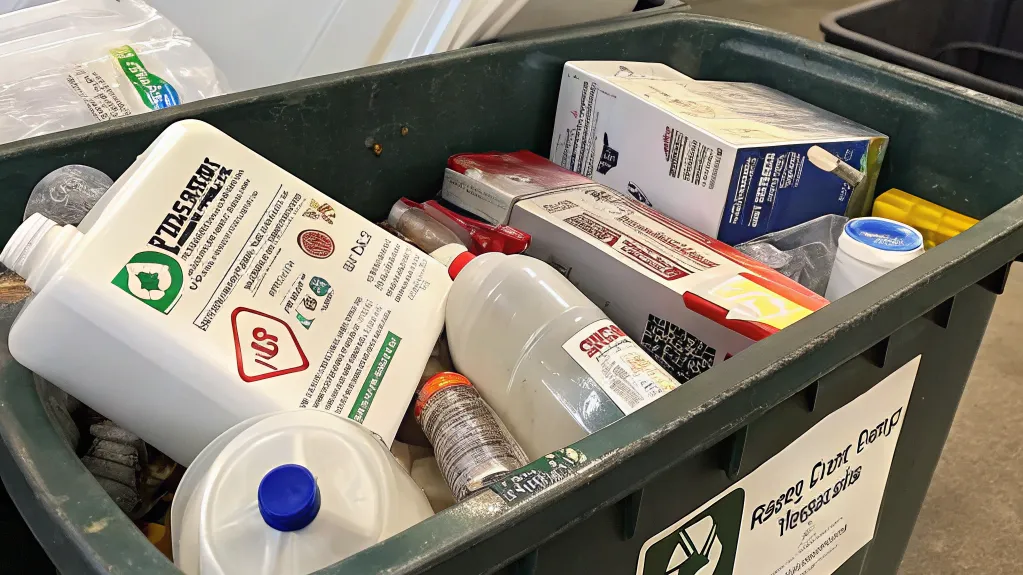

Rigid plastics, including items like containers, bottles, and sturdy goods, form a considerable part of plastic waste. Recycling these materials not only preserves resources but also mitigates environmental impact. Here’s how to choose the most suitable machine for recycling rigid plastics:

1. Identify the types of plastics you’ll recycle

• HDPE (High-Density Polyethylene): Commonly found in milk jugs, detergent bottles, and grocery bags.

• PET (Polyethylene Terephthalate): Used in beverage bottles and food packaging.

• PP (Polypropylene): Seen in yogurt containers, straws, and bottle caps.

• PVC (Polyvinyl Chloride): Utilized in pipes, siding, and wrapping materials.

• ABS (Acrylonitrile Butadiene Styrene): Often used for electronic housings and automotive components.

Each type has distinct properties that may necessitate specific recycling technologies. For instance, HDPE can be processed using a shredder and an extruder, while PET might require extra steps such as washing to eliminate residues.

2. Machine efficiency and capacity

• Throughput: Calculate the daily plastic volume you intend to process. Machines vary in size, with capacities from 80 kg/hr to over 1000 kg/hr.

• Energy efficiency: Seek machines with energy-saving features. Contemporary equipment often incorporates optimized motors or systems to lower energy use, which is vital for controlling costs and promoting sustainability.

3. Durability and maintenance

• Material quality: Machines made with premium steel or other resilient materials ensure extended service life. Durable machines endure the demands of continuous operation.

• Ease of maintenance: Choose machines designed for simple cleaning and part replacement to minimize downtime. Look for models offering straightforward maintenance processes.

4. Technology and features

• Sorting and cleaning: Effective sorting systems, such as optical sorters or sink-float separators, greatly improve the quality of recycled materials. Washing lines are critical for eliminating contaminants, as highlighted by Genius Machinery.

• Automation: Automatic feeding, real-time monitoring, and self-cleaning features can substantially boost productivity while reducing labor costs.

• Filtration systems: As emphasized by POLYSTAR’s Repro-Flex, efficient filtration removes impurities, crucial for producing superior-quality pellets.

5. Safety and environmental compliance

• Safety features: Verify that the machine includes safety interlocks, emergency stops, and protective enclosures to ensure worker safety.

• Environmental impact: Machines with closed-loop water systems or designs that minimize waste are advantageous. This conserves resources and aligns with regulatory requirements.

6. Brand reputation and support

• Recognized brands: Brands like Vecoplan, Rumtoo, and HERBOLD are known for their expertise in plastic recycling machinery. Opt for brands with robust service support for troubleshooting and maintenance.

• Customer reviews and case studies: Seek feedback or success stories from businesses similar in size or type of plastic processed.

7. Cost vs. ROI

• Initial investment: Although lower-cost machines may seem appealing, consider long-term savings from improved efficiency and superior output quality.

• Operational costs: Machines that save on energy, labor, and maintenance provide a better return on investment over time.

8. Training and usability

• User training: Machines should come with detailed operator training to ensure optimal and safe usage.

• User-friendly interface: Modern machines with intuitive controls help reduce the learning curve and improve operational efficiency.

Incorporating best practices

• Regular maintenance: Following a strict maintenance schedule ensures machine longevity and sustained efficiency.

• Staff training: Continuous education on safety and operational best practices helps maintain smooth and compliant operations.

• Optimizing automation: Take full advantage of automation features to enhance productivity and reduce manual labor.

By considering these factors, businesses can efficiently manage rigid plastic waste, transforming it into a valuable resource while reducing environmental impact. This guide draws from insights provided by industry leaders such as CP Manufacturing and practical expertise from pioneers like POLYSTAR, helping you select a machine that meets both operational needs and environmental objectives.