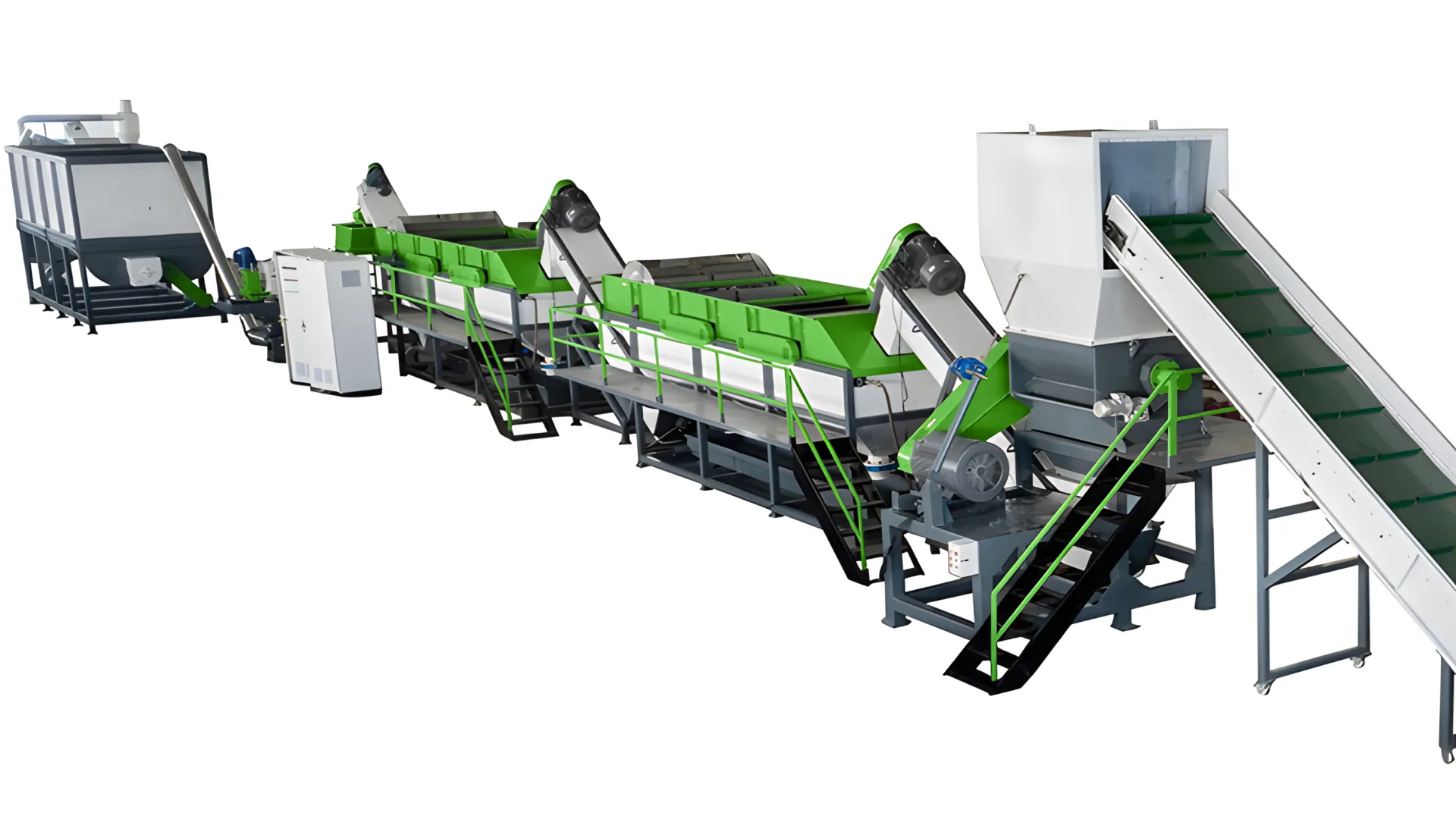

High-Performance Rigid Plastic Recycling Washing Line

Transform post-consumer and post-industrial rigid plastics like PP, HDPE, ABS, and PVC into high-value, clean regrind ready for profitable reuse.

Request a Custom SolutionFrom Waste Crates to Premium Regrind

Advanced recycling solutions for diverse rigid plastic materials

PP Regrind

Ideal for producing durable goods like chairs, automotive parts, pipes, and containers.

HDPE Regrind

Widely used for bottles, pipes, and playground equipment due to its high strength and chemical resistance.

PVC Regrind

Perfect for pipes, flooring, cable insulation, and window frames, valued for its durability.

ABS Regrind

Sought after for automotive parts, electronics housings, and toys due to its toughness and finish.

PET Regrind

Excellent for new bottles and food containers, offering superior clarity and barrier properties.

Mixed Rigid Plastics

Our lines can be configured to sort and process diverse waste streams from various industries.

Our Comprehensive Cleaning & Separation Process

Six-step system for optimal recycling results

Sorting & Pre-washing

Removes large contaminants and prepares materials for size reduction.

Granulation

Material is efficiently reduced to smaller, uniform flakes for deep cleaning.

Intensive Washing

A high-friction wash removes stubborn labels, dirt, and adhesives.

Density Separation

Floating tanks separate desired plastics (PP/PE) from sinking contaminants.

Dewatering

Centrifugal force removes the majority of water content efficiently.

Thermal Drying

A final hot air drying stage achieves optimal moisture levels for extrusion.

See Our Washing Line in Operation

Key Components of Our Washing Line

Industry-leading machinery and components

Wet Plastic Granulator

This robust granulator simultaneously cuts and pre-cleans rigid plastics, increasing efficiency and blade longevity.

- Blade Material: Durable D2 high-carbon, high-chromium steel

- Cutting Design: High-efficiency V-shape or double-scissor cut

- Benefit: Reduces dust and loosens surface contaminants early on

High-Speed Friction Washer

Uses high rotational speeds to create intense friction, effectively scrubbing away dirt, sand, and other adhered contaminants.

- Rotor Speed: 500-600 RPM for powerful cleaning action

- Operation: Continuous process for seamless line integration

- Function: Cleans and conveys material to the next stage

Floating Separation Tank

Precisely separates plastics based on density. Lighter plastics like PP and PE float, while heavier contaminants and other plastics sink.

- Construction: Corrosion-resistant Type 304 Stainless Steel interior

- Efficiency: Unique “W” shaped bottom improves separation

- Process: Cleans material while simultaneously separating it

Continuous Hot Washer

Essential for removing stubborn contaminants like oils, grease, and glues from materials such as post-consumer PET and HDPE bottles.

- Method: Hot chemical bath combined with high-speed friction

- Performance: Achieves superior cleaning in a single, continuous cycle

- Result: Produces exceptionally clean flakes for high-end applications

Centrifugal Dryer (Dewatering)

A low-energy dewatering unit that uses centrifugal force to mechanically remove the bulk of surface water from the plastic regrind.

- Speed: High-speed rotation (approx. 1,000 RPM) for efficiency

- Moisture Target: Reduces initial moisture to around 20-30%

- Versatility: Suitable for all types of rigid plastic regrinds

Thermal Dryer System

The final drying stage, employing a hot air dehydration system to achieve final moisture levels below 1%, critical for high-quality extrusion.

- Technology: Hot air circulation through stainless steel pipes

- Purity: Integrated cyclone separator removes fine dust

- Scalability: Modular design allows for increased capacity

Key Advantages of Our Technology

Eco-Friendly & Efficient

Our systems are optimized for reduced water and energy consumption, lowering your operational costs.

Premium Output Quality

Superior cleaning technology produces high-grade, pure regrind ready for profitable reuse.

Robust & Versatile

Our modular lines are built to last and can be configured to process various types of rigid plastic waste.

Frequently Asked Questions

Can this line separate different types of rigid plastics?

Yes, the core of our separation technology is the Floating Separation Tank, which effectively separates plastics based on density. It is excellent at separating floating plastics like PP and HDPE from sinking plastics like PVC and PET, as well as other heavy contaminants.

What is the final purity and moisture level I can expect?

Our systems are designed to achieve high levels of purity, often exceeding 99%, depending on the input material. The final moisture content after our thermal drying system is typically below 1%, which is ideal for direct use in high-quality extrusion and molding.

How do you handle materials with labels and metal components?

Our process is multi-staged. The Wet Granulator and Friction Washer are very effective at detaching paper and plastic labels. For metal components, we typically recommend installing an overband magnet and/or a metal detector before the granulator to protect the machinery and ensure final product purity.

Is the system modular and can it be customized?

Absolutely. Modularity is a key feature. We design each line based on the client’s specific input materials, contamination levels, and desired output capacity. We can add, remove, or resize components to create the most efficient and cost-effective solution for your facility.

Transform Your Rigid Plastic Waste into a Valuable Asset

Contact our engineering team today to discuss your project and receive a customized, no-obligation quote.

Get Your Free Quote Today