Small Crusher Machine for Plastic Bottles

RUMTOO small plastic bottle crusher delivers uniform flakes in a compact footprint. V‑type knives, replaceable screens, and easy maintenance fit small to mid‑scale recycling lines.

Key Advantages

Compact Footprint

Space‑saving design installs easily in small workshops or alongside existing lines.

Efficient Crushing

Optimized V‑type blade layout for fast, consistent cutting with stable throughput.

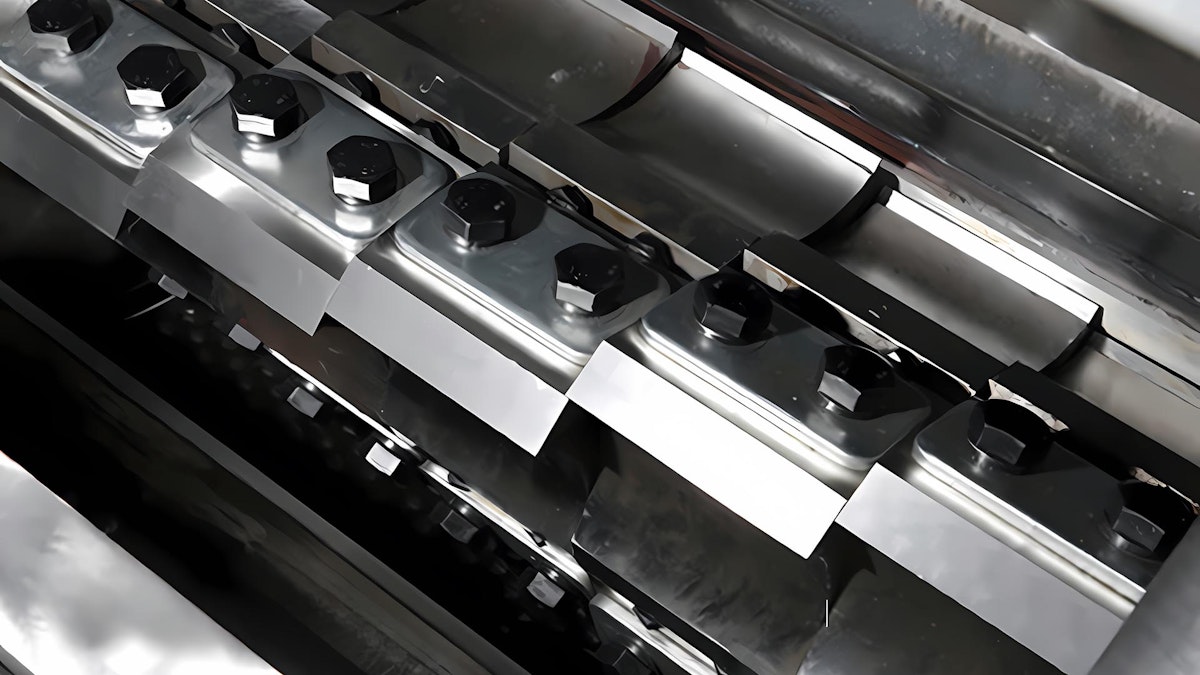

Durable Knives

Hardened steel knives in V‑type (scissor) configuration extend service life and cut clean.

How It Works

Simple, reliable size‑reduction for bottles and other small rigid plastics.

Inside the Crushing Chamber

- V‑type or scissor‑type knife geometry for clean, efficient cutting.

- Replaceable screen with selectable apertures to match flake size targets.

- Quick access for maintenance and knife sharpening.

- Optional soundproof hopper and safety interlocks available from rumtoo.

Applications

Bottles

PET water/juice bottles, HDPE milk jugs, cosmetic and household containers.

Small Rigids

Thin‑walled parts, small injection moldings, light‑wall pipes and fittings.

Line Integration

Pairs with conveyors, blowers, and washing lines for continuous recycling.

Frequently Asked Questions

Can it handle bottles with caps and labels?

Yes. PET/HDPE bottles with PP/PE caps and labels can be crushed together. Different materials are separated later in the washing and separation line.

Crusher (granulator) vs. shredder?

Granulators run at higher speed and use a screen to produce small, uniform flakes — ideal for hollow items like bottles. Shredders are low‑speed, high‑torque for bulky items and pre‑crushing.

Knife maintenance interval?

Depends on material and hours. For clean PET/HDPE, knives often run for long intervals before sharpening. Knives are re‑sharpenable multiple times.

Can it crush plastics other than bottles?

Yes. Effective for thin‑walled or small rigid plastics such as small containers and light‑wall pipes. Not recommended for very thick, dense blocks or soft films.

Get a Quote

Share your material, target flake size and layout. The RUMTOO team will recommend configuration and pricing.