Wet Plastic Granulator Machine

RUMTOO wet granulator integrates water into the cutting chamber to cool blades, pre‑wash plastics, and suppress dust — delivering cleaner flakes, longer knife life, and smoother downstream washing and pelletizing.

Why Wet Granulation?

Compared with dry cutting, wet granulation from RUMTOO reduces heat, dust, and contamination while improving flake cleanliness and machine longevity.

Typical Issues (Dry Cutting)

- Blade heating causes faster wear and potential melting/smearing on plastics.

- High dust levels, requiring more housekeeping and filters.

- Contaminants remain on the surface, increasing load on washing lines.

RUMTOO’s Wet Solution

- Continuous water spray cools knives and material to protect cutting edges.

- In‑chamber pre‑washing removes dirt, labels, and residues upfront.

- Less dust, cleaner flakes, and more stable downstream processing.

How It Works

A robust cutting system with integrated water delivers clean, uniform flakes.

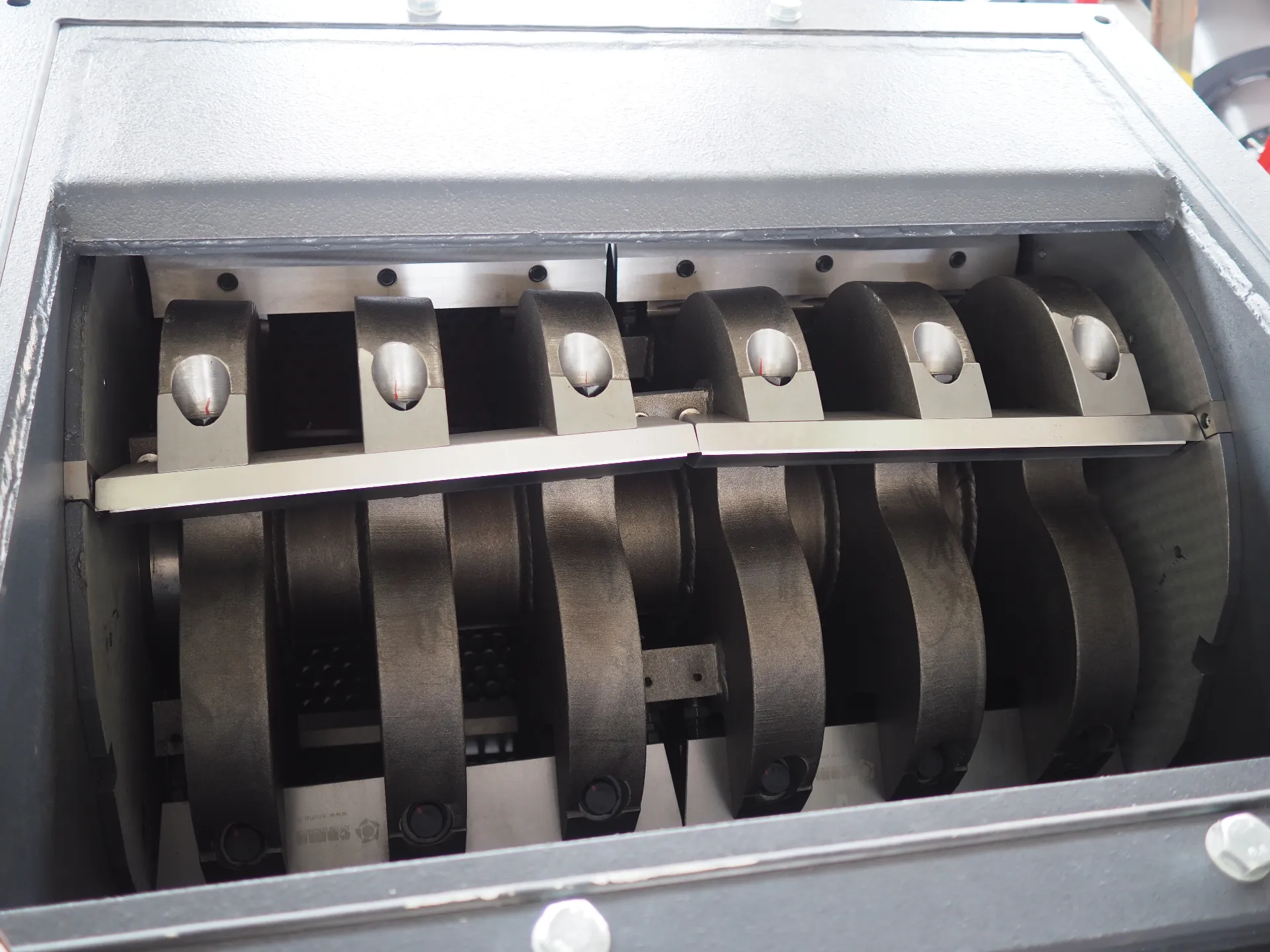

Engineered for Clean, Cool Cutting

Open rotor with ultra‑durable D2 knives rotates at 400–600 rpm. Water injection cools the cutting zone, washes the surface, and suppresses dust — a practical upgrade recommended by the rumtoo engineering team for high‑contamination streams.

Product In Action

See the wet granulator’s robust structure and steady cutting performance.

Key Advantages

Effective Pre‑Cleaning

Integrated spray loosens dirt, food residues, paper and labels, improving downstream washing efficiency.

Lower Heat & Wear

Water cools blades and material, extending knife life and keeping cuts sharp and uniform.

Less Dust, Safer Shop

Wet cutting suppresses dust at the source for a cleaner, safer environment.

Versatile Applications

Designed to handle both flexible and rigid plastics in recycling lines.

Bottles & Rigid

- PET bottles, HDPE jugs

- Drums, buckets, crates

Films

- LDPE/LLDPE packaging film

- PP woven bags and raffia

Pre‑washing Role

Acts as the first cleaning step before friction washers, sink‑float tanks, and dewatering equipment.

Granulator vs. Shredder

A granulator is a high‑speed cutter for secondary size reduction, producing uniform flakes. A shredder is low‑speed, high‑torque for primary reduction of bulky or tough items. In high‑capacity lines, a shredder often feeds a granulator for final refinement.

Frequently Asked Questions

Which plastics work best with a wet granulator?

Common inputs include PET bottles, HDPE/PP rigid containers, drums, buckets, LDPE/LLDPE films, and PP woven bags. For very thick or bulky items, pair with a shredder first — our RUMTOO team can advise.

Will water increase corrosion or contamination?

Critical components use wear‑resistant materials. Proper water quality and routine cleaning prevent scale or deposits. Downstream equipment separates water and solids before further washing and drying.

What screen sizes are available?

Standard screens range from 10–100 mm. Select larger apertures for high‑throughput pre‑washing, or smaller sizes for tighter flake control.

How does it integrate into a washing line?

Typical flow: Feeding → Wet Granulator → Friction Washer → Sink‑Float Tank → Dewatering → Dryer. rumtoo can tailor the layout for your plant.

Get a Quote & Warranty Details

All recycling machines include a 1‑year limited warranty. Share your material, capacity and layout — the RUMTOO team will respond with sizing and pricing.