Plastic Film Washing Line

RUMTOO engineers modular PP/PE film washing lines that transform heavily contaminated film into clean, dry flakes ready for pelletizing. Each line is configured for your feedstock, layout, and moisture targets.

Built for International Recycling Projects

Rumtoo combines European safety standards with decades of plastic washing know-how. We tailor the line around contamination level, film type, and downstream pelletizing goals.

Common Bottlenecks

- Inconsistent cleaning results when switching between LDPE film, stretch wrap, and woven bags.

- High moisture (>15%) causing steam, bubbles, and feeding disruptions at the extruder.

- Complex layouts that waste floor space and require excessive operators.

Rumtoo Optimized Solution

- Configurable pre-treatment line-up (bale breaker, shredder, or wet granulator) for smooth feeding.

- Dual-stage friction and float separation backed by stainless steel contact zones.

- Mechanical + hot air drying package that meets global export moisture specs.

Complete Washing Workflow

A proven sequence that balances cleaning performance, energy efficiency, and operator safety.

Feed Preparation

De-baling, label removal, and magnetic separation prepare film for steady flow without tangles.

Size Reduction

Heavy-duty shredder or wet granulator slices film into 20–40 mm pieces while dosing water.

High-Impact Washing

Friction washer spins at ~1,000 RPM to scrub away organics, paper, and glue residues.

Float-Sink Separation

Customized tanks remove heavier particles while Rumtoo skimming design keeps water clean longer.

Mechanical Dewatering

Centrifugal dryers or our film squeezer reduce moisture by up to 80% before thermal treatment.

Final Drying & Buffer

Hot air pipes and cyclone silo deliver stable, low-dust flakes to pelletizing or agglomeration.

Applications & Feedstock Profiles

From municipal recycling plants to agricultural film recovery, Rumtoo designs each washing line to match the real-world materials you process daily.

Post-Consumer Film Recovery

Curbsided LDPE/LLDPE films, supermarket stretch wrap, and retail bags with labels, sand, and organic residue.

Outcome: Clean flakes certified below 1,000 ppm contamination for pelletizing into new film products.

Agricultural & Silage Film

Heavily soiled mulch films and silage wraps containing soil, stones, and fertilizer residues.

Rumtoo focus: Upgraded friction washing and tank agitation prevent mud build-up and shorten water change cycles.

Industrial Packaging Loops

Production scrap, pallet covers, and bubble film returned from logistics hubs seeking closed-loop reuse.

Result: Consistent, low-dust flakes ready for in-house compounding or blown film extrusion.

Woven Bag & Big Bag Upgrade

PP woven bags, raffia, and FIBCs with printing inks and bulk contamination from food or chemical handling.

Rumtoo advantage: Tailored drying and pelletizing integration to achieve stable feed density for PP extrusion.

Export-Grade Pellet Projects

Facilities aiming to meet EU and US import standards for recycled pellets with strict moisture and odor limits.

Support: Rumtoo engineers benchmark moisture, odor, and whiteness targets during commissioning.

Key Equipment Modules

Select the modules you need—Rumtoo engineers integrate controls, platforms, and piping so the line installs fast and runs predictably.

Heavy-Duty Bale Breaker

Unwinds compressed films safely and meters feed to avoid shock loads on downstream grinders.

Wet Granulator Shredding

Hardened knives and water curtain keep film cool, reduce dust, and launch the cleaning process.

Multi-Stage Washing

Stainless steel friction washers and zig-zag separators remove mud, paper, and light caps.

Centrifugal & Thermal Drying

Matched mechanical and hot-air dryers hit target moisture without melting or curling the film.

Smart Control Panel

Industry-grade PLC with remote support, recipe presets, and alarms in your language of choice.

Global Commissioning

Rumtoo technical teams handle installation, operator coaching, and preventive maintenance plans.

Optimized Footprint

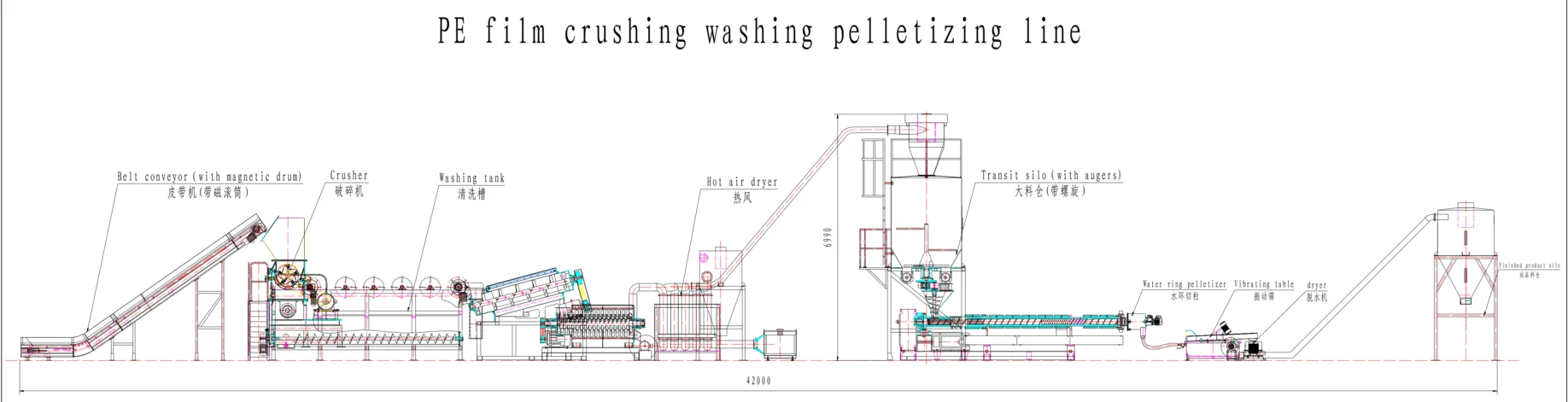

Sample layout for a 1,000 kg/h Rumtoo washing line. We adapt tank orientation, mezzanines, and utilities to suit your facility.

Watch the Line in Action

See how Rumtoo integrates shredding, washing, drying, and pelletizing into a continuous process.

Technical Specifications

Standard Rumtoo configurations. We can adapt layout, voltage, and material handling to match your project brief.

| Line Capacity (kg/h) | Required Space (L×W×H) | Recommended Operators | Installation Power (kW) | Water Circulation (T/H) |

|---|---|---|---|---|

| 500 | 42 m × 15 m × 6 m | 2 – 3 people | 250 | 2 |

| 1,000 | 50 m × 15 m × 6 m | 3 – 5 people | 350 | 3 |

| 1,500 | 60 m × 25 m × 6 m | 4 – 6 people | 470 | 3 |

| 2,000 | 80 m × 30 m × 6 m | 4 – 6 people | 650 | 4 |

| 3,000 | 80 m × 40 m × 6 m | 7 – 9 people | 850 | 5 |

Frequently Asked Questions

Answers to the questions Rumtoo receives most often from North American and European buyers.

Which plastic films can Rumtoo washing lines process?

Our lines handle post-consumer LDPE, LLDPE, HDPE film, stretch wrap, agricultural mulch film, and woven PP bags. We validate cleaning performance with material samples before manufacturing.

Can I integrate the washing line with existing pelletizing equipment?

Yes. Rumtoo engineers match discharge moisture, bulk density, and feeding height to your current pelletizer or compounding extruder. We can supply a complete pelletizing package if needed.

How long does installation and commissioning take?

A standard 1,000 kg/h line installs in roughly 25–30 working days including electrical wiring, water balancing, and operator training. Larger custom projects may require an additional 1–2 weeks.

What after-sales support does Rumtoo provide?

You receive a one-year warranty, lifetime technical support, and optional preventive maintenance visits. Remote diagnostics and spare parts stocking plans keep uptime high.

Start Your Rumtoo Washing Line Project

Share your feedstock mix, contamination level, utility availability, and target capacity. Our engineers will return a tailored process layout, budget, and timeline.