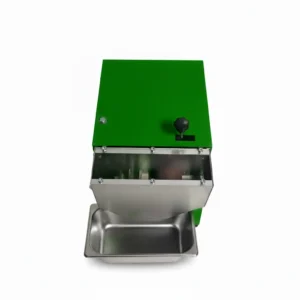

Laboratory Plastic Extruder

The Professional Lab Extruder is a cutting-edge, high-precision extruder designed for small-scale production and material testing. Engineered to process a variety of polymers and composites, this versatile machine ensures accurate temperature, screw speed, and pressure control for consistent results in research and development applications.

- Precision Engineering: Achieve perfect material extrusion with fine-tuned control.

- Flexible Processing: Supports a range of materials from thermoplastics to composites.

- Energy Efficient: Reduces energy consumption while maintaining top performance.

Perfect for R&D, material testing, and small-batch production!

描述

Core Advantages

Precision Engineering

Highly accurate extrusion process for research, development, and material testing with precise temperature control.

Flexible Processing Capabilities

Designed for a variety of materials, including polymers, composites, and more, with customizable settings for specific needs.

Energy-Efficient Operation

Minimizes energy consumption while maintaining optimal performance, saving costs and supporting sustainable practices.

Product Overview

Working Principle

How It Works

The lab extruder utilizes precise temperature and screw speed controls to melt and process various polymer materials into desired shapes or forms for testing. The system is designed to simulate large-scale production while offering flexibility for small-batch operations.

- Accurate temperature and screw speed control for precise extrusion

- Supports a wide range of materials, including thermoplastics and composites

- Ideal for lab-scale production and material testing

- Easy-to-use interface for fast setup and operation

Technical Specifications

Standard Model

- Capacity: Customizable based on requirements

- Material: Type 304 stainless steel

- Motor Power: Adjustable for different processing needs

- Warranty: 1 year limited

Ready to Upgrade Your Lab Extrusion Capabilities?

Contact us for pricing and customization options