0

Countries / Regions Served

Industrial Plastic Recycling Systems

From individual machines to turnkey washing and pelletizing plants. Factory-direct execution with global engineering support.

Trust Signals

0

Countries / Regions Served

0

Equipment & Line Projects

0

Engineering & Service Team

0

Industry Experience

Product Categories

Industrial shredders, crushers, and pulverizers for controlled particle preparation.

Learn MoreIntegrated washing modules for PET, films, and rigid streams with contamination control.

Learn MoreConfigured extrusion and pelletizing routes for stable recycled material output.

Learn MoreDesktop and pilot equipment for fast process validation and material development.

Learn MoreWhy Rumtoo

Process and equipment design focused on line stability, contamination control, and output consistency.

Installation, commissioning, and operator training support for international project deployment.

From line planning and module selection to startup and optimization under one engineering workflow.

Material-Based Solutions

High-purity PET flake routes for bottle, sheet, and fiber-grade downstream applications.

View Solution

Process architecture for soft, wet, and contaminated flexible plastic streams.

View Solution

Robust size reduction and conditioning route for HDPE, PP, and engineering rigid streams.

View Solution

Closed-loop workflows from print scrap to reusable pellets or filament feedstock.

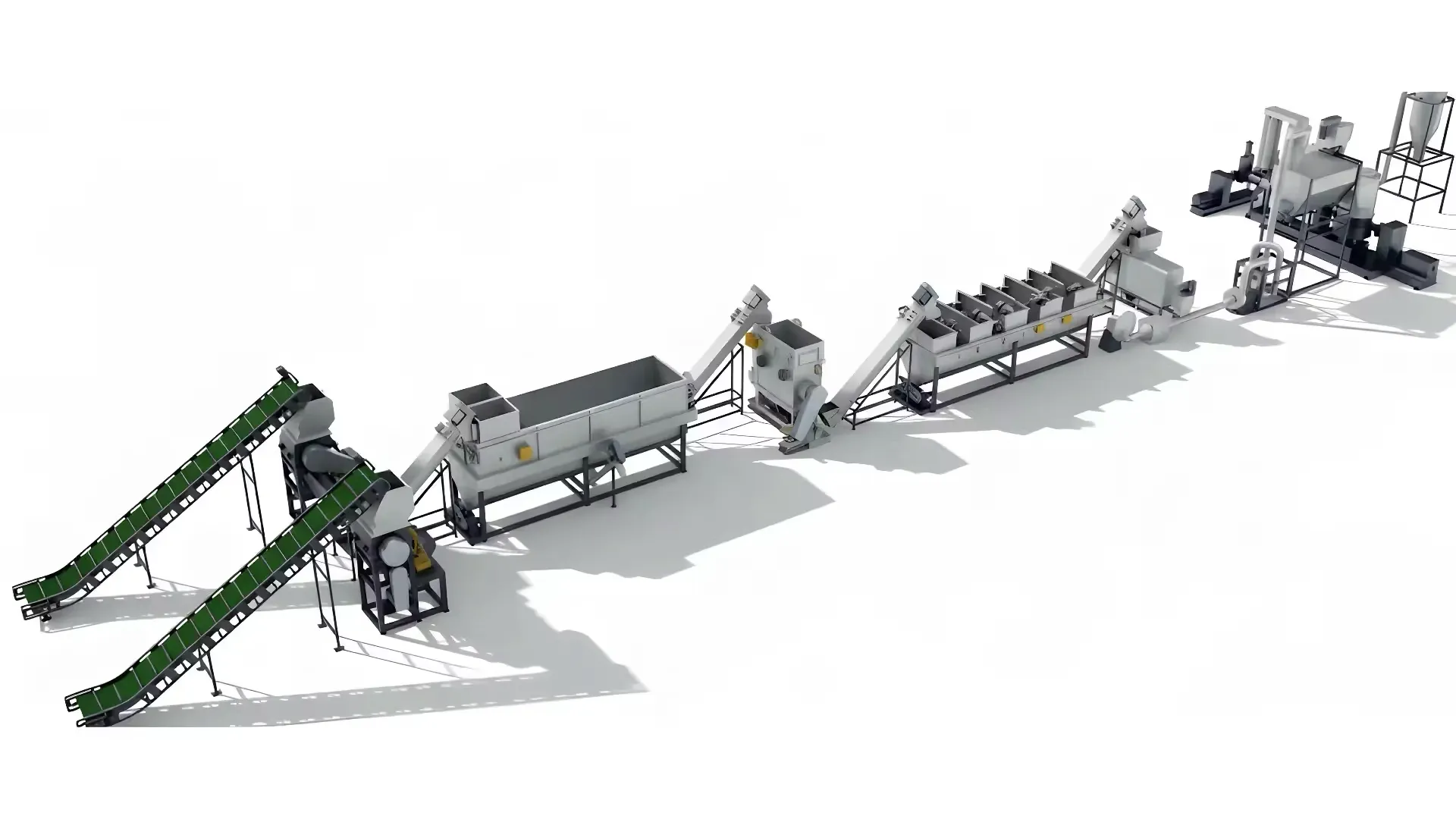

View SolutionMachine Process Flow

Stage 1

Bulky plastics are reduced into controlled-size feed suitable for continuous processing.

Stage 2

Multi-stage cleaning removes contaminants, labels, and mixed material fractions.

Stage 3

Mechanical and thermal modules stabilize moisture before extrusion and quality control.

Stage 4

Clean feed is converted into consistent recycled pellets for downstream manufacturing.

Trust & Content

Discover how to choose the right plastic recycling machine. Learn about shredding, washing, pelletizing lines, ROI optimization, and real-world throughput for your recycling facility.

Read Article

Recycling plant KPI dashboard template for tracking throughput, quality, downtime, and energy at line and plant level.

Read Article

Preventive maintenance checklist for plastic recycling washing lines to reduce unplanned downtime and protect quality output.

Read Article

Crusher and shredder configuration guide for matching cutting stages to PET bottles, rigid plastics, and film feedstock.

Read ArticleFrequently Asked Questions

Our industrial recycling systems process a wide range of materials including PET bottles, PE/PP agricultural films, rigid plastics (HDPE/PP), and 3D printing waste into high-quality reusable pellets.

Yes, we design, manufacture, and install complete turnkey lines covering shredding, washing, drying, and pelletizing, tailored to your specific feedstock and factory layout.

We ensure high-output purity through multi-stage friction washing, precise density separation, and advanced thermal drying and vacuum degassing during the extrusion phase.

Absolutely. Our heavy-duty shredders and specialized hot washing modules are engineered specifically to handle post-consumer waste with high levels of dirt, oil, and paper labels.

Yes, our global engineering team provides on-site installation, system commissioning, and comprehensive operator training worldwide to ensure your plant runs smoothly.

Tell us your material type and target throughput. We will return a modular line recommendation and deployment roadmap.