Plastic Film Squeezer Machine

RUMTOO’s Plastic Film Squeezer efficiently dewaters and densifies washed plastic films, reducing moisture to 1-5% for optimal recycling and enhanced extruder performance.

The Challenge of Wet Plastic Films

Recycling post-consumer plastic films presents significant hurdles, primarily due to high moisture content after washing.

Common Problems

- Washed film typically holds up to 40% moisture, complicating further processing.

- Standard vertical dryers often leave 20-30% residual water in lightweight film flakes.

- Inconsistent feeding in recycling extruders and reduced output efficiency.

RUMTOO’s Solution

- Reduces moisture from 10-35% down to an exceptionally low 1-5%.

- Significantly faster drying compared to traditional centrifugal or hot air methods.

- Transforms loose film into high-density lumps for stable feeding into extruders.

From Waste Film to Densified Material

RUMTOO’s streamlined three-step transformation process.

Key Features & Benefits

Engineered by RUMTOO for maximum efficiency in plastic film recycling.

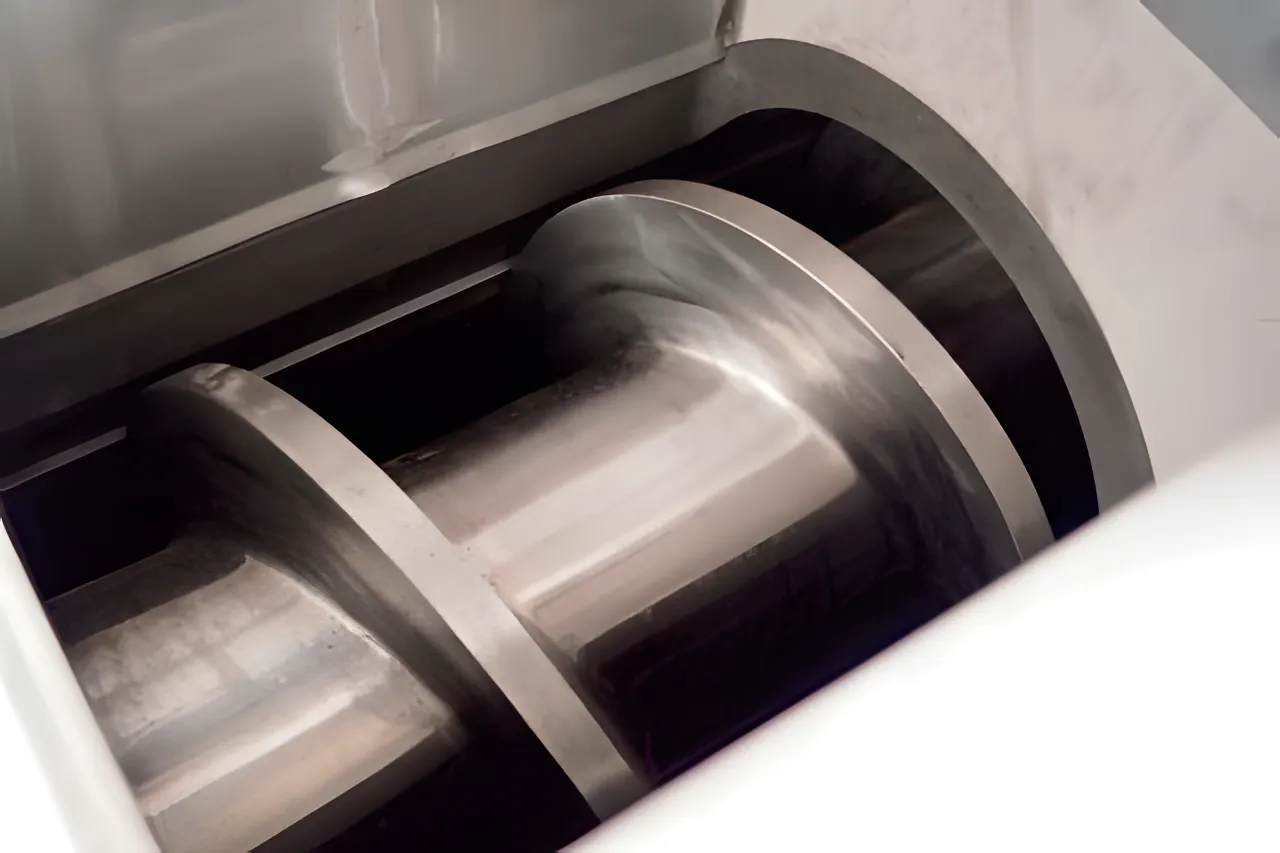

How It Works: The Squeezing Process

RUMTOO’s five-step dewatering and densification process.

Technical Specifications

RUMTOO offers multiple models to match your production requirements.

Note: Primary heating is from friction/pressure. Main motor power varies with configuration. Contact RUMTOO for detailed specifications.

Product In Action

See RUMTOO’s Film Squeezer Machine in operation.

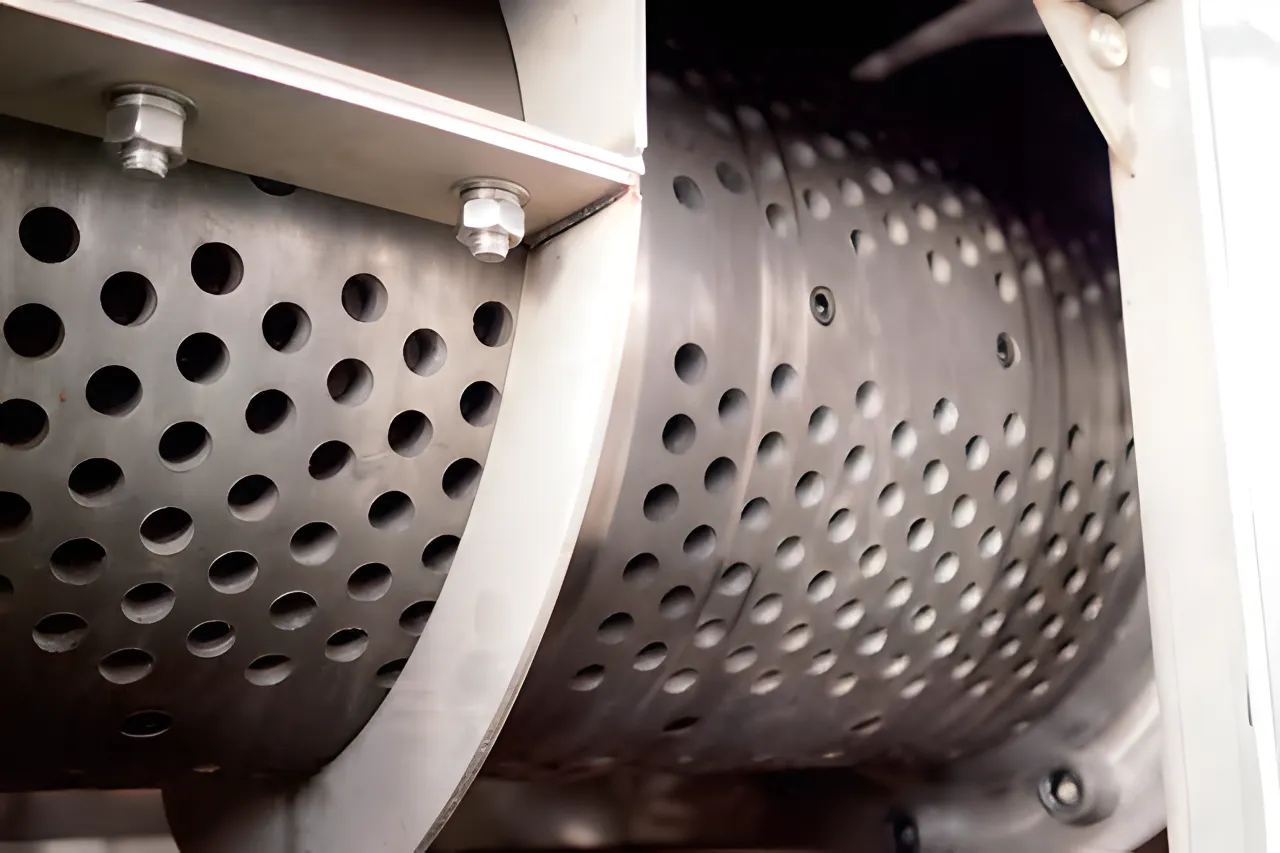

Machine Views

Seamless Integration with Your Washing Line

Maximize Your Output

Specially designed by RUMTOO to fit between the washing line and plastic recycling extruder, our squeezer optimizes the output and efficiency of compactor-extruder-pelletizing type recycling machines.

Typical Workflow Enhancement

Washing Line → Film Squeezer → Recycling Extruder

This strategic placement ensures pre-dried, densified material feeds perfectly into your extruder.

Frequently Asked Questions

Get answers to common questions about RUMTOO’s Film Squeezer Machine.

Why is a squeezer essential for plastic film recycling?

Plastic films hold significant moisture (up to 40%) after washing. Traditional dryers are often ineffective. RUMTOO’s squeezer drastically reduces this moisture to 1-5%, preventing extruder issues and improving output quality and efficiency.

What types of plastic film can this machine process?

RUMTOO’s squeezer is suitable for various washed plastic films, primarily PE (Polyethylene) and PP (Polypropylene) films, including post-consumer films, agricultural films, and industrial film waste.

How does the squeezer improve pellet quality?

By reducing moisture significantly and densifying the material, RUMTOO’s squeezer ensures a more consistent and stable feed into the pelletizing extruder. This minimizes voids and imperfections, leading to higher-quality, more uniform pellets.

Can this machine be integrated into existing recycling lines?

Yes, RUMTOO’s Film Squeezer is designed for seamless integration between your washing line and pelletizing extruder. Our engineers can assist with installation planning and setup to ensure optimal performance within your existing infrastructure.

What is the typical power consumption?

Power consumption varies by model and configuration. The primary heating comes from friction and pressure during the squeezing process, making it energy-efficient. Contact RUMTOO for detailed power specifications for your chosen model.

How does RUMTOO’s squeezer compare to traditional drying methods?

RUMTOO’s squeezer is significantly faster than traditional centrifugal or hot air dryers, especially for lightweight film flakes. It achieves lower moisture levels (1-5% vs 20-30%), uses less energy, and causes minimal material degradation due to the gentle mechanical drying process.

What warranty and after-sales support does RUMTOO offer?

Each RUMTOO recycling machine, including our film squeezer, comes with a 1-year limited warranty covering manufacturing defects. We provide installation services where our engineers can visit your site to assist with setup. Maintenance, operator training, and ongoing technical consultancy can also be arranged.

Revolutionize Your Film Recycling with RUMTOO

Ready to overcome moisture challenges and boost your plastic film recycling efficiency? Contact us for the latest prices, lead times, and a customized proposal.