High-Output Plastic Pulverizer

The Rumtoo MF series pulverizers are engineered for grinding mid-hard, brittle, and high-impact plastics like PE, PVC, and PC into fine powder. Designed for high-output applications, these machines transform granulated input material (6-8 mm) into valuable, reusable powder.

- High output for industrial-scale operations

- Adjustable mesh size for output flexibility

- Integrated water cooling to prevent material degradation

- Closed-loop system for low energy use and minimal dust

How Our Plastic Pulverizer Works

Our MF Series utilizes a proven disc grinding principle to transform plastic granules into fine, uniform powder through a precise, multi-stage process.

1. Material Feeding

Pre-crushed PVC material (typically 6-8mm) is fed into the grinding chamber via a vibrating feeder, ensuring a consistent and stable flow.

2. High-Speed Grinding

Inside the chamber, a high-speed rotating disc works against a fixed disc. The material is pulverized by the intense shearing and cutting forces in the precisely controlled gap between them.

3. Screening & Collection

The resulting powder is drawn out by a fan and enters a vibrating sieve. Powder that meets the size requirement is collected, while oversized particles are automatically sent back for re-grinding.

Key Operational Advantages

High Output

Handles substantial throughput, ensuring efficient processing for industrial needs.

Precision Gap Control

The gap between rotating and fixed discs is externally adjustable for precise particle size control.

Quick Maintenance

Designed for fast and easy access to blades and screens, minimizing downtime during maintenance.

Robust Construction

Features a heavy-duty, welded steel housing built for durability and stable, long-term operation.

Energy Efficient

Optimized drive system consumes less energy compared to similar products, reducing operational costs.

Closed-Loop System

The fully enclosed design minimizes dust pollution and material loss, ensuring a clean working environment.

Technical Specifications

The MF series efficiently processes a variety of materials, turning waste into reusable granules. Here’s a closer look at their capabilities based on technical parameters.

| Feature | MF-500 | MF-600 | MF-800 |

|---|---|---|---|

| Main Power | 2.2 KW | 4 KW | 4 KW |

| Rotating Diameter | 500 mm | 600 mm | 800 mm |

| Fan Power | 4 KW | 5.5 KW | 11 KW |

| Number of Blades | 12+24 | 13+26 | 15+32 |

| Vibration Screen Dia. | 800 mm | 1000 mm | 1200 mm |

| Production Output | 150-200 kg/h | 200-450 kg/h | 500-800 kg/h |

| Weight | 1500 kg | 2000 kg | 2800 kg |

Choosing the Right Model

Select the MF model that best fits your production requirements.

A smart choice for smaller operations or pilot projects, delivering a production capacity of 150-200 kg/h.

Suitable for mid-sized facilities with larger production demands, with a capacity from 200-450 kg/h.

The most robust option for large-scale industrial applications, boasting an output of 500-800 kg/h.

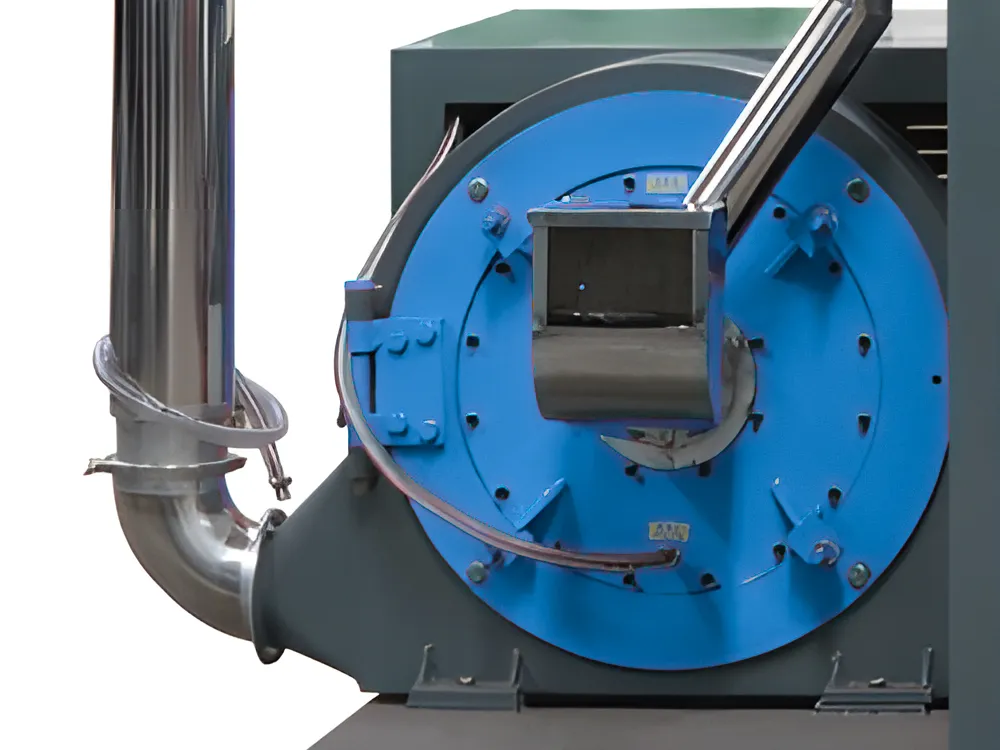

Plastic Pulverizer: Detailed Views

A closer look at the robust construction and key components of the MF Series pulverizer, from the cooling water inlet to the precision grinding blades.

The Role of Powder Fineness

The fineness of the output powder significantly affects its suitability for different manufacturing processes.

Fine Powders (<30 mesh)

Used in rotational molding, coatings, and some extrusion processes where a smooth finish is essential.

Medium Granules (30-80 mesh)

Common in injection molding and extrusion, offering a good balance of flowability and mechanical properties.

Coarse Granules (>80 mesh)

Suitable for certain extrusion processes and applications where surface finish is less critical.

Frequently Asked Questions

Find answers to common questions about the MF Series Plastic Pulverizer.

What types of PVC can this machine process?

Our MF series pulverizers are highly versatile and can efficiently process both rigid and flexible PVC materials. This includes post-industrial waste like pipes, window profiles, sheets, and production scraps, turning them into high-quality reusable powder.

How do I adjust the output powder size?

You have two primary controls for particle size. First, the fineness can be precisely adjusted by changing the gap between the fixed and rotating grinding discs. Second, the final output size is determined by the mesh size of the vibrating sieve installed after the grinding chamber.

Does the machine require a water cooling system?

Yes, a water cooling system is essential and integrated into the design. The grinding chamber, bearings, and discs are all water-cooled to effectively dissipate heat generated from high-speed friction. This prevents the PVC material from melting, sticking, or degrading, ensuring a high-quality powder output and protecting the equipment.

What is the maintenance schedule for the blades?

Blade life depends heavily on the type and cleanliness of the material being processed. We recommend regular weekly inspections. The blades are crafted from high-wear-resistant alloy steel and are designed to be sharpened multiple times before needing replacement, ensuring low operational costs.

Discuss Your Pulverizing Needs

Share your material type, capacity requirements, and target particle size. Rumtoo will return a tailored configuration and quote for the ideal MF pulverizer.

- 24/7 engineering hotline & remote commissioning

- Integrates with Rumtoo washing and pelletizing lines

- Global support for blades, screens, and motors